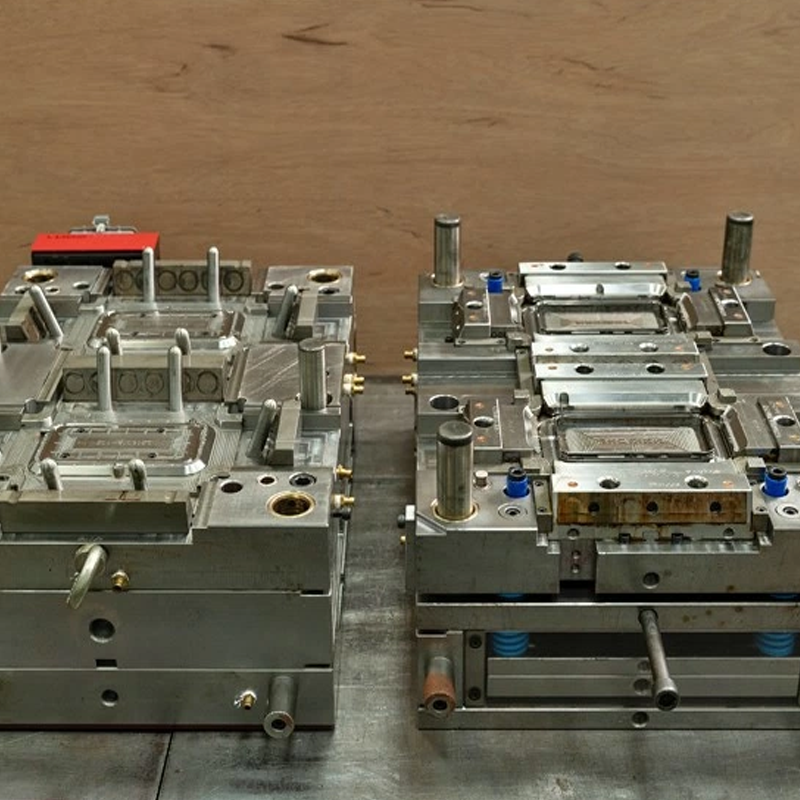

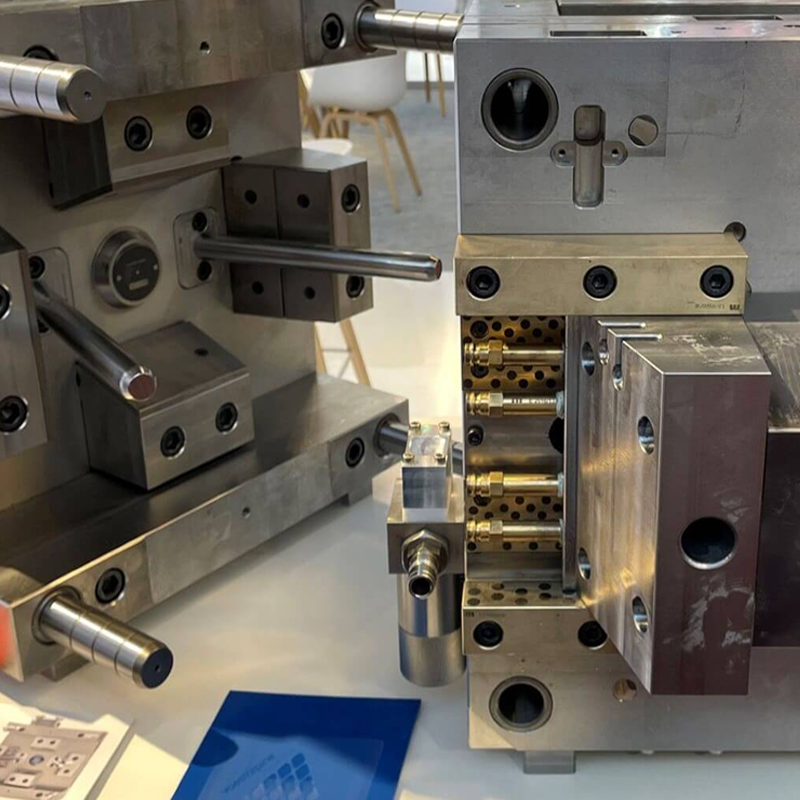

Injection molding has become one of the most refined and versatile manufacturing processes worldwide. Whether you’re producing tiny components no larger than a fingernail or large parts like automotive doors, injection molding is a reliable solution for mass production. The key to its efficiency lies in creating precise molds that ensure consistent output. For businesses looking to manage production costs, selecting the right country for mold-making services can be crucial—sometimes more important than other factors like material or design.

At LSRmold, we understand that injection mold-making requires precision, efficiency, and cost-effectiveness. As a leading provider of Liquid Silicone Rubber (LSR) molding services, we have worked with clients globally, helping them optimize costs while maintaining the high quality that the injection molding process demands. In this blog, we’ll explore injection mold-making services across key manufacturing countries like China, Mexico, India, and Southeast Asia, offering a comparison of costs and considerations to guide your decision-making.

Key Factors Influencing Injection Mold Manufacturing Costs

When selecting a manufacturing location, several factors directly impact the cost of injection mold-making. Below are the primary considerations to take into account:

Material Costs

The raw materials used in injection molding—both the metal for the molds and the plastic resins for injection—have a significant impact on manufacturing expenses. Availability, quality, and the overall market conditions of the materials used can drive costs up or down. Bulk buying and high production volumes often enable manufacturers to negotiate better prices on raw materials, reducing costs for the final product.

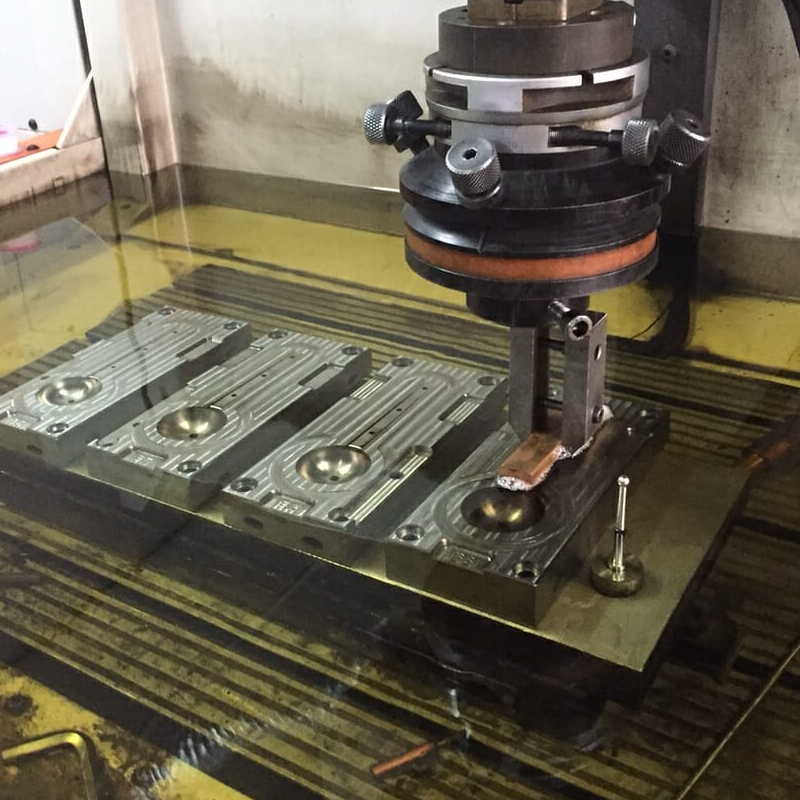

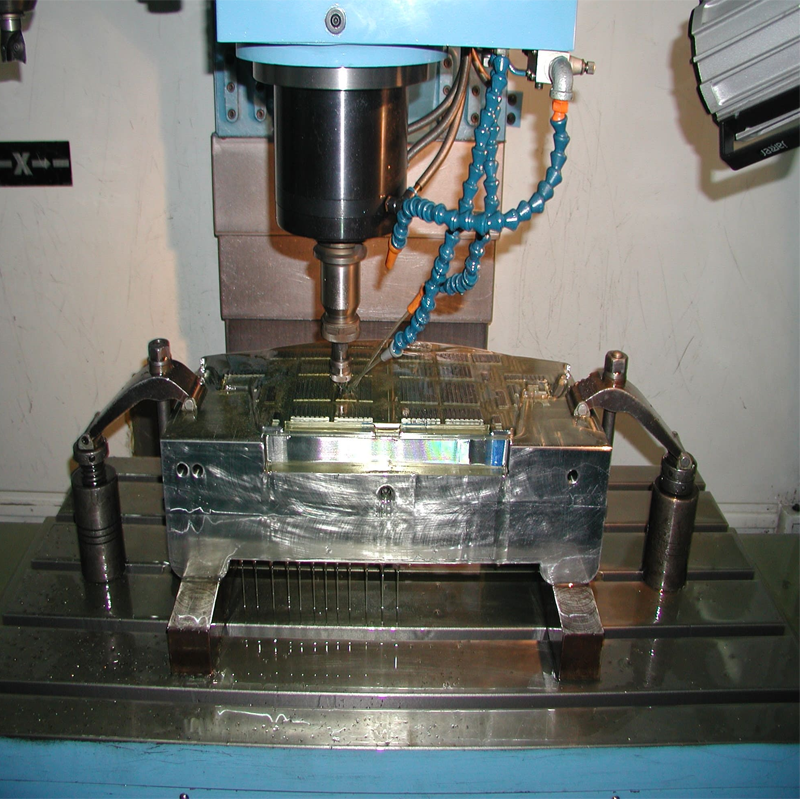

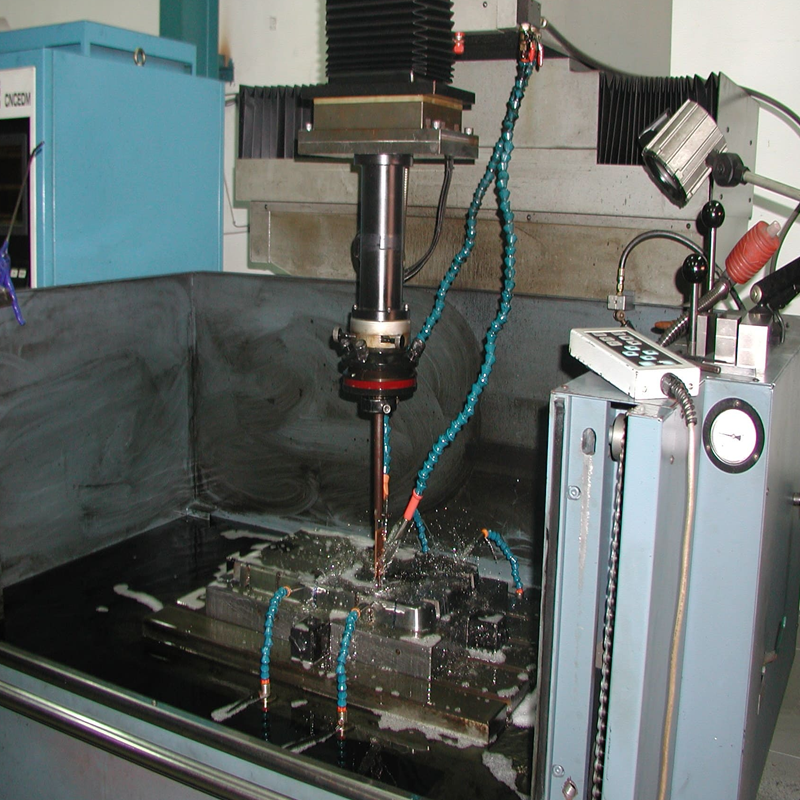

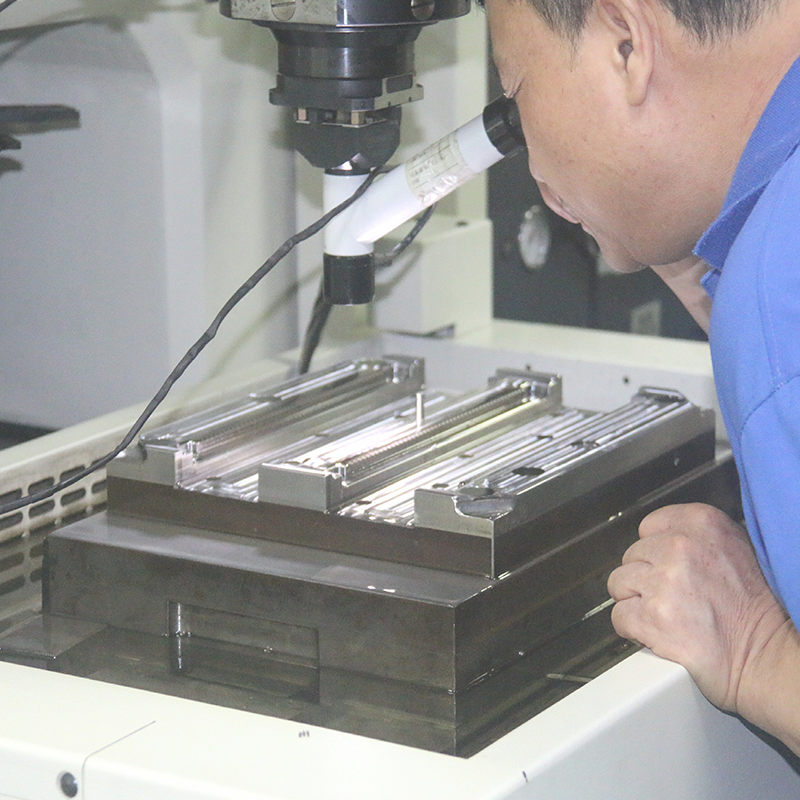

Machine Power and Efficiency

The efficiency of the machines used in the molding process plays a crucial role in reducing overall production costs. High production volumes lower the cost per unit, and manufacturers that optimize their operations can improve efficiency, reduce production time, and minimize energy consumption. Efficient machinery can reduce production costs significantly, especially in automated systems like LSR molding, which is often employed for high-precision applications.

Mold Design and Complexity

The complexity of the mold design affects both the material costs and labor costs. Intricate designs may require additional materials and more advanced tooling, which increases the overall cost. Even small changes in design can result in significantly different pricing.

Labor Costs

Labor costs vary from country to country, and they play a substantial role in determining overall manufacturing costs. In countries with lower labor wages, manufacturers can save on production costs, but quality control and skilled labor are essential to achieving the necessary precision in mold-making.

Manufacturing Location

Geography has a significant impact on costs. Proximity to suppliers, shipping costs, and local taxes all influence the total cost of manufacturing. For example, Mexico’s proximity to the U.S. makes it an attractive location for businesses looking to save on shipping costs and reduce lead times.

Technology and Equipment

The quality and type of machinery used for mold-making affect both the speed and accuracy of production. Countries with advanced manufacturing technologies, like LSR molding systems and automated injection molding machines, tend to produce more precise molds, but the initial cost of setting up these systems may be higher.

Leading Countries for Affordable Injection Molding Services

Several countries have become well-established as global leaders in injection molding services due to their competitive pricing and reliable service. At LSRmold, we work closely with manufacturers in regions like China, Mexico, India, and Southeast Asia to help clients make the best decision for their needs.

1. China: A Global Leader in Injection Molding

China has long been a powerhouse for injection molding services, offering affordable pricing, a large manufacturing base, and advanced technological capabilities. The country’s extensive infrastructure and experienced workforce make it an attractive option for high-volume production, though costs have been rising as wages increase.

Advantages of Mold-Making in China:

- Cost Efficiency: China offers cost advantages, particularly for large orders. Volume discounts make it an excellent choice for bulk production.

- Massive Production Capacity: China has more than 580,000 mold-making factories, which makes it ideal for handling large-scale projects.

- Technological Advancements: Continuous investment in machinery and automation has improved efficiency and precision in mold-making.

- Developed Infrastructure: China’s established supply chain minimizes material and transportation costs.

Challenges:

- Language and Cultural Barriers: Communication can be challenging for businesses unfamiliar with Chinese language and business culture.

- Intellectual Property Concerns: Although many factories in China now implement non-disclosure agreements (NDAs), the risk of intellectual property theft remains.

At LSRmold, we’ve worked extensively with manufacturers in China to help businesses take advantage of its cost-effective molding services while ensuring quality and protection for proprietary designs.

2. Mexico: An Attractive Option for North American Businesses

Mexico offers a significant cost advantage for businesses looking to produce injection molds close to North American markets. The country’s proximity to the U.S. reduces shipping times and transportation costs, while labor costs remain competitive compared to China.

Advantages of Mold-Making in Mexico:

- Lower Labor Costs: Mexico’s labor costs are lower than those in the U.S. and rising labor costs in China, making it an attractive option for North American companies.

- Reduced Transportation Costs: With proximity to the U.S., transportation costs are significantly reduced, offering quicker turnaround times for manufacturers.

- Duty-Free Access: Mexico’s free trade agreements, such as USMCA, provide tariff-free access to North American markets, further reducing costs.

- Shorter Supply Chains: Companies in Mexico benefit from shorter supply chains, reducing the lead time and costs associated with international shipments.

Challenges:

- Limited Production Capacity Compared to China: While Mexico has a strong manufacturing presence, it doesn’t match China’s sheer scale of production.

- Quality Control Variability: While quality standards in Mexico are high, businesses must ensure that manufacturers adhere to international standards.

3. India: Cost-Effective with Low Labor Costs

India has emerged as a cost-effective alternative for injection molding, thanks to its low labor costs, favorable exchange rates, and modern manufacturing capabilities. The country is attracting more foreign investment due to government initiatives such as “Make in India” and its robust manufacturing infrastructure.

Advantages of Mold-Making in India:

- Low Labor Costs: India offers some of the lowest labor costs globally, which makes it an attractive choice for companies focused on cost reduction.

- Skilled Labor: India’s pool of skilled engineers and technicians has bolstered its reputation as a reliable injection molding destination.

- Government Support: Initiatives like SEZs (Special Economic Zones) help reduce taxes and facilitate a business-friendly environment.

Challenges:

- Quality Control: While India has made significant strides in quality, businesses must carefully vet suppliers to ensure high-quality production.

- Logistics: Shipping times from India can be longer, especially for companies located in the U.S. or Europe.

4. Southeast Asia (Vietnam, Thailand, Indonesia)

Countries like Vietnam, Thailand, and Indonesia have rapidly become global manufacturing hubs due to their skilled labor forces, strategic locations, and favorable economic conditions. These regions are particularly attractive to businesses seeking lower labor costs than China, with the added benefit of trade agreements like ASEAN Free Trade Area (AFTA).

Advantages of Mold-Making in Southeast Asia:

- Competitive Labor Costs: Southeast Asia offers affordable labor, making it a cost-effective choice for high-volume injection molding.

- Strategic Location: Countries in this region are well-connected to global supply chains, reducing transportation costs.

- Emerging Markets: Southeast Asia’s rapidly growing economy and improving infrastructure make it an attractive manufacturing destination.

Challenges:

- Inconsistent Quality: Not all manufacturers in Southeast Asia offer the same level of quality, making supplier selection critical.

- Language and Cultural Barriers: Like China, communication can be a challenge for businesses unfamiliar with local practices.

Cost Comparison: Injection Molding in China vs. Mexico vs. India vs. Southeast Asia

When comparing injection molding costs across these regions, businesses should consider both the direct costs (e.g., labor, materials, logistics) and indirect costs (e.g., quality control, intellectual property protection). Here’s a quick breakdown:

| Country | Labor Costs | Material Costs | Transportation Costs | Quality Control |

|---|---|---|---|---|

| China | Low to Moderate | Competitive | Higher for exports | High |

| Mexico | Moderate | Competitive | Low | High |

| India | Very Low | Low | Moderate | Moderate |

| Southeast Asia | Low | Competitive | Moderate | Varies |

Conclusion: Selecting the Right Injection Mold-Making Location

Choosing the right country for injection mold-making services is critical for achieving cost savings, high quality, and reliable production. At LSRmold, we understand the complexities involved in selecting a manufacturing location. We assist our clients in making informed decisions based on their specific needs.

Are you ready to optimize your injection mold-making process and achieve cost-effective solutions? Contact LSRmold today to discuss your needs, and let us help you find the perfect manufacturing solution for your project.