When sourcing high-quality mold-making supplies, selecting the right mold supplier is crucial to ensure the success of your project. As a leading manufacturer, LSRmold understands that choosing a professional mold supplier goes beyond simply considering pricing and delivery times. A reliable supplier must provide a complete range of mold-making products, offer precise, high-quality components, and be able to meet specific production requirements. In this blog, we will explore five essential questions to ask when choosing the right mold supplier for your business needs.

1. What is the Purpose of the Injection Mold and How Does It Impact Your Project?

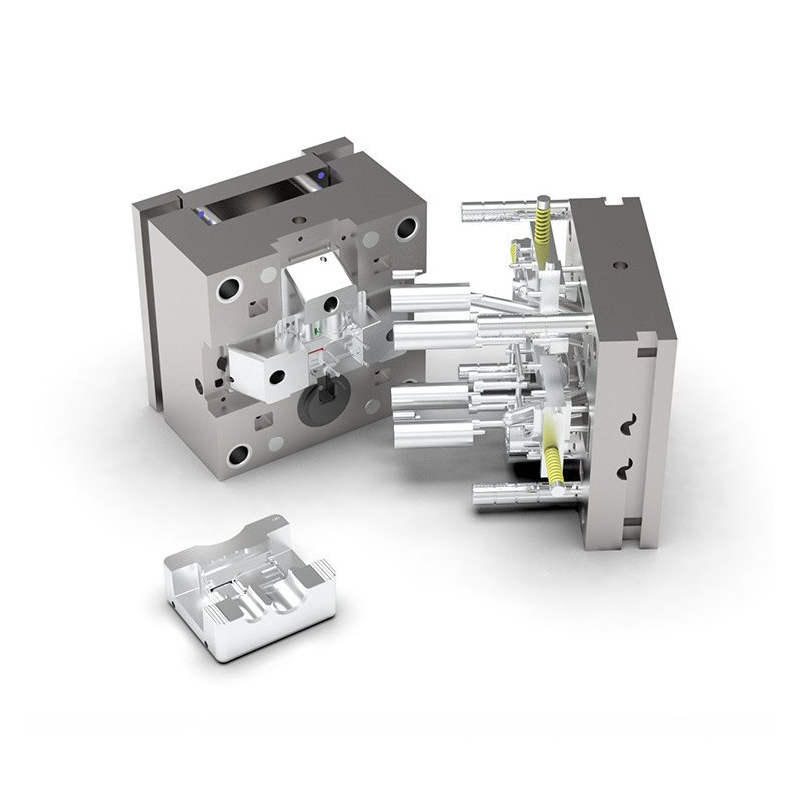

Understanding the primary purpose of an injection mold is crucial to making the right decision. A mold’s efficiency, such as its ability to dissipate heat quickly, plays a key role in reducing cycle times and increasing production efficiency. The faster the cooling process, the faster the part is produced, reducing overall costs and lead times.

At LSRmold, we focus on designing molds with efficient melt delivery and cooling systems. By ensuring that these systems are precisely engineered, we can minimize cycle times and scrap, which ultimately leads to cost savings. The type of steel, mold size, slide actions, and location of tool construction are all factors that contribute to the cost and performance of the mold. Make sure your mold supplier fully understands these aspects to help you optimize the production process and minimize operational costs.

2. Are You Paying Your Supplier on Time and Are You Getting the Best Deal?

While paying promptly to suppliers may seem like a simple aspect, it can actually have a significant impact on your project’s overall costs. LSRmold recommends having clear, upfront conversations with your supplier regarding payment schedules and potential discounts for early payments. Paying on time can help to establish a long-term working relationship with your supplier, which may result in future cost savings or better terms on subsequent orders.

By negotiating favorable terms, you can avoid incurring additional costs from late payments or project delays. As a high-precision mold manufacturer, we at LSRmold ensure that we provide fair pricing without sacrificing quality, and we always work with our clients to meet their specific needs.

3. What Is the Total Cost of the Mold?

This is one of the most frequently asked questions when selecting a mold supplier. Understanding the total cost of the mold is essential because the upfront cost of the mold is one of the largest expenses in manufacturing. Be sure to request a clear and detailed price breakdown from your supplier.

At LSRmold, we understand that pricing transparency is important for our customers. We provide our clients with a clear breakdown of mold costs, including design, tooling, and production costs. Whether you’re looking for prototype molds for small production runs or mass-production molds for large-scale manufacturing, we offer cost-effective solutions without compromising on quality. Our team works closely with customers to provide high-precision molds tailored to meet their exact specifications.

4. Does the Mold Supplier Meet Your Exact Needs?

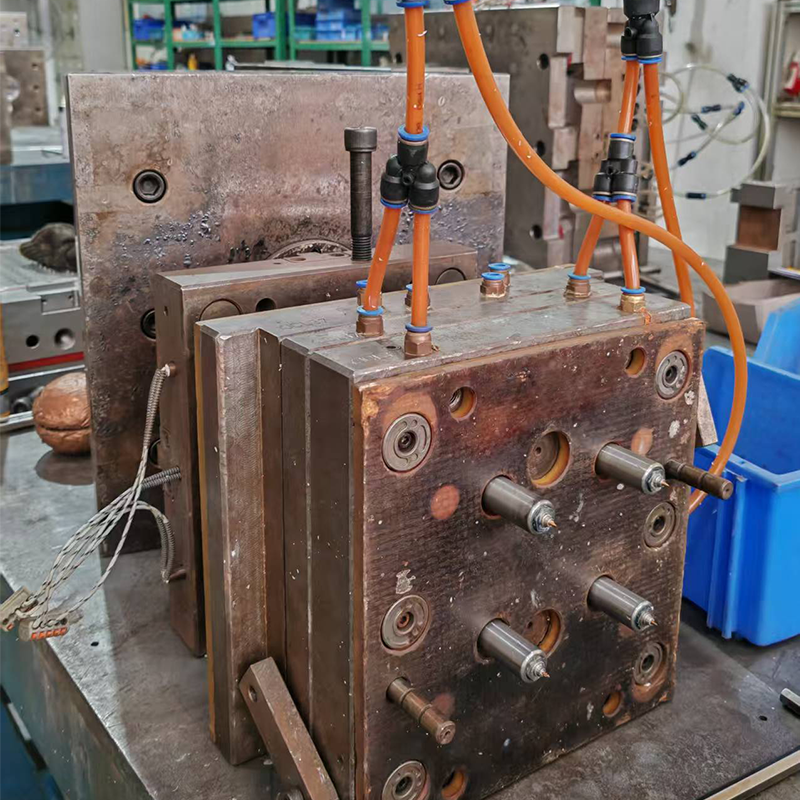

It’s essential to work with a supplier who understands your business requirements and can adapt to changes as needed. Unfortunately, some suppliers may not have the financial stability or necessary resources to meet ongoing project needs. Ensure that your supplier has a solid business foundation, a history of reliable deliveries, and a commitment to quality manufacturing.

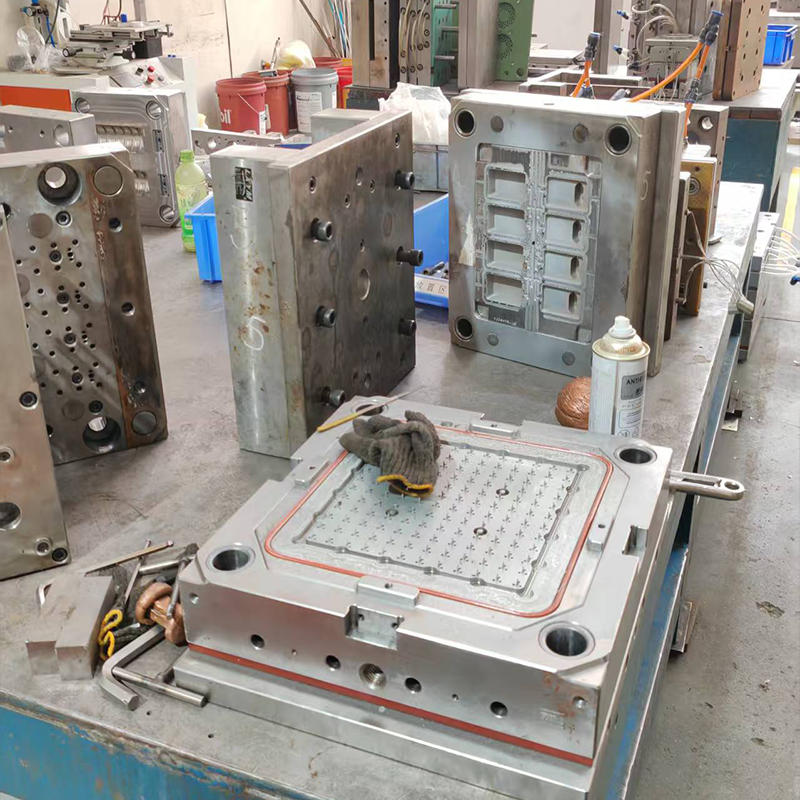

LSRmold excels in providing both high-volume and low-volume molds, offering the flexibility to adapt to any project, regardless of its scale. Our team works diligently to ensure that your mold meets your expectations, with continuous improvements through training programs, modern equipment, and future-focused investments. This enables us to handle projects efficiently, from prototype molds to high-precision, large-scale manufacturing.

5. How to Ensure You’ve Chosen the Right Mold Supplier?

Choosing the right mold supplier can sometimes be challenging. The supplier must not only provide high-quality products but also meet your production timelines and provide excellent customer service. Before making a final decision, review the supplier’s reputation and past work to ensure they have the necessary experience in delivering molds for your specific industry.

At LSRmold, we pride ourselves on our reputation as a leading mold manufacturer. We provide high-precision, custom services tailored to your unique needs. Our extensive portfolio of successful projects includes plastic injection molds, die-casting molds, and other custom tooling solutions. We are committed to offering one-stop services to meet the needs of our clients, ensuring that we provide high-quality, precision molds for industries ranging from automotive to consumer goods.

Why Choose LSRmold for Your Mold Manufacturing Needs?

Choosing the right mold supplier is crucial for the success of any manufacturing project. At LSRmold, we stand out from other suppliers due to our:

- Comprehensive Capabilities: We provide a wide range of mold solutions, including injection molds, die-casting molds, and precision parts, ensuring we can meet your unique needs.

- Custom Solutions: Our design and engineering teams work closely with clients to create custom solutions, ensuring that every mold meets your specific performance and quality requirements.

- High Precision Manufacturing: With our state-of-the-art equipment and highly skilled team, we offer precision molds that meet the most stringent industry standards.

- Quality Assurance: At LSRmold, we adhere to strict quality control measures throughout the production process, ensuring that every mold is manufactured to the highest standard. Our high-quality products have made us a trusted partner in the mold manufacturing industry.

- On-Time Delivery and Competitive Pricing: We understand the importance of meeting deadlines and delivering products within budget. Our team works efficiently to ensure timely deliveries without compromising quality.

Get in Touch with LSRmold for Your Custom Mold Manufacturing Needs

Choosing the right mold supplier is a crucial decision for your business, and at LSRmold, we are committed to providing the best possible solutions for your project. Whether you’re looking for prototype molds, mass production molds, or anything in between, we offer high-quality, precise, and custom solutions that meet your unique requirements.

If you’re ready to get started on your next project or need more information about our capabilities, contact LSRmold today. Our team is ready to work with you every step of the way, ensuring that you receive the best molds for your manufacturing needs. Let us help you bring your vision to life with our high-precision molds and superior customer service.