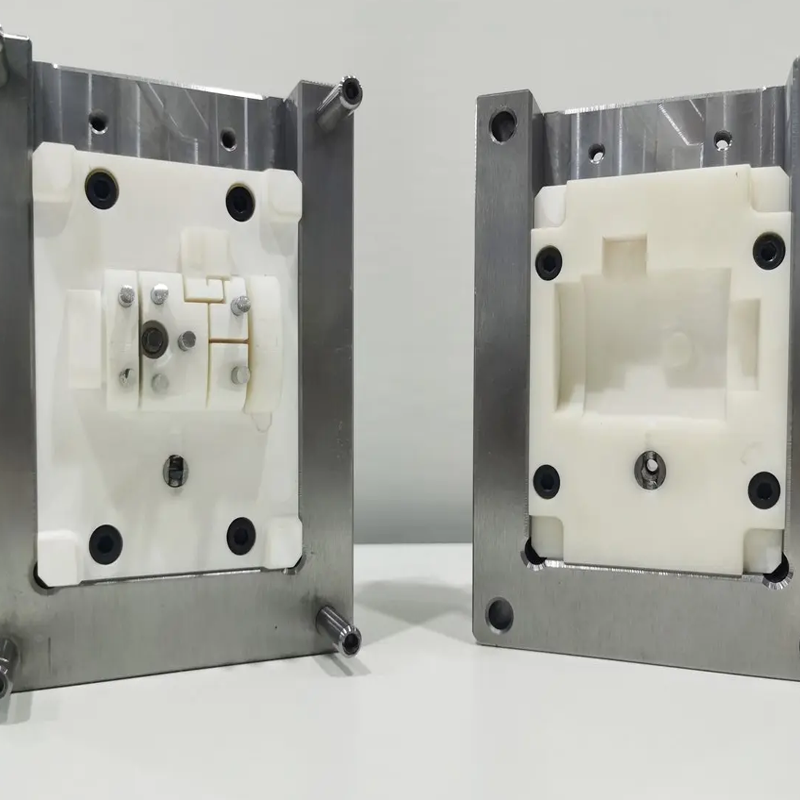

In today’s manufacturing world, companies are constantly evaluating new technologies to speed up production, reduce costs, and optimize their processes. One such advancement that has gained attention is 3D printing, specifically for creating molds for injection molding. While 3D-printed molds can offer rapid prototyping and cost-effective solutions for low-volume production, they may not always be the best option for all applications.

At LSRmold, we specialize in high-quality custom injection molding and tooling. In this blog, we’ll explore the differences between 3D-printed molds and aluminum tooling, focusing on how each method impacts precision, durability, cost, and manufacturing efficiency. Let’s dive into when each method is best suited for your injection molding needs and how our team of experts ensures that your project meets the highest standards of performance and cost-effectiveness.

The Key Differences Between 3D-Printed Molds and Aluminum Tooling

When it comes to selecting the right mold-making technique for your project, understanding the strengths and weaknesses of both 3D-printed molds and aluminum tooling is critical. While 3D printing may seem like a cost-effective alternative, there are important considerations that can make aluminum tooling the more reliable and durable choice for high-volume production.

1. Quality and Surface Finish

The surface finish quality of a mold directly affects the final product’s appearance and performance. While 3D printing has come a long way in terms of precision, it still falls short when it comes to achieving the smooth, flawless surface finishes required for many industrial applications.

3D-Printed Molds:

3D printing builds objects layer by layer, which can leave a stair-step effect on angled surfaces or walls. This can lead to imperfections in the surface finish, especially for parts that require tight tolerances or a smooth texture. While additional sanding and machining can mitigate these issues, the speed advantage of 3D printing is diminished as a result.

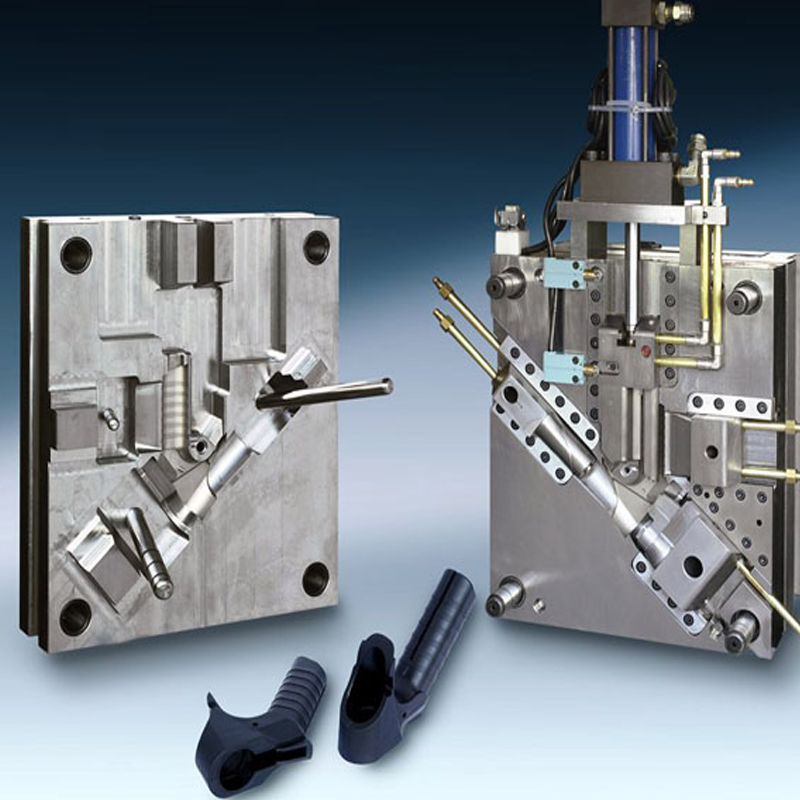

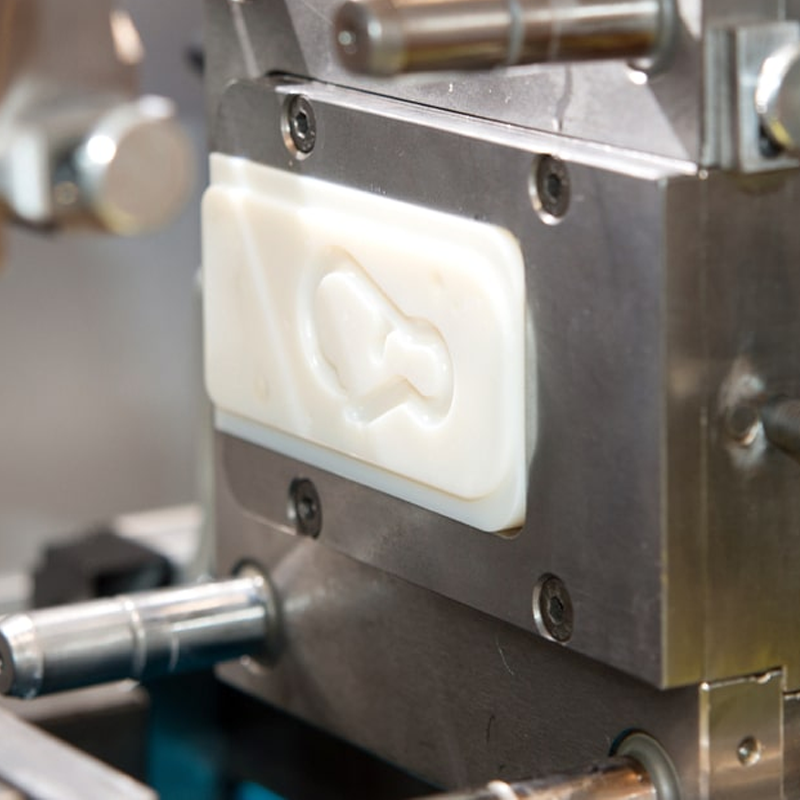

Aluminum Tooling:

In contrast, aluminum molds can achieve high-quality surface finishes without the need for extensive post-processing. The smooth, precise mold surfaces created by aluminum tooling ensure that the finished parts come out with a high-quality surface, without the need for additional sanding or adjustments.

At LSRmold, we use state-of-the-art CNC machining and electrical discharge machining (EDM) technologies to ensure our aluminum tooling delivers superior surface finishes with tight tolerances, making it ideal for parts that require high levels of precision.

2. Material Performance and Durability

The durability of a mold is critical, especially for high-volume production. The performance of 3D-printed molds under high temperatures and pressure is limited compared to traditional metal molds.

3D-Printed Molds:

Although 3D printing can produce molds quickly, they typically have a much shorter lifespan than aluminum molds. A printed mold made from thermoplastic or photopolymer resins can only withstand approximately 100 shots before it begins to degrade, especially under the high temperatures and pressures used in injection molding. This means that 3D-printed molds may not be suitable for long-term, high-volume production.

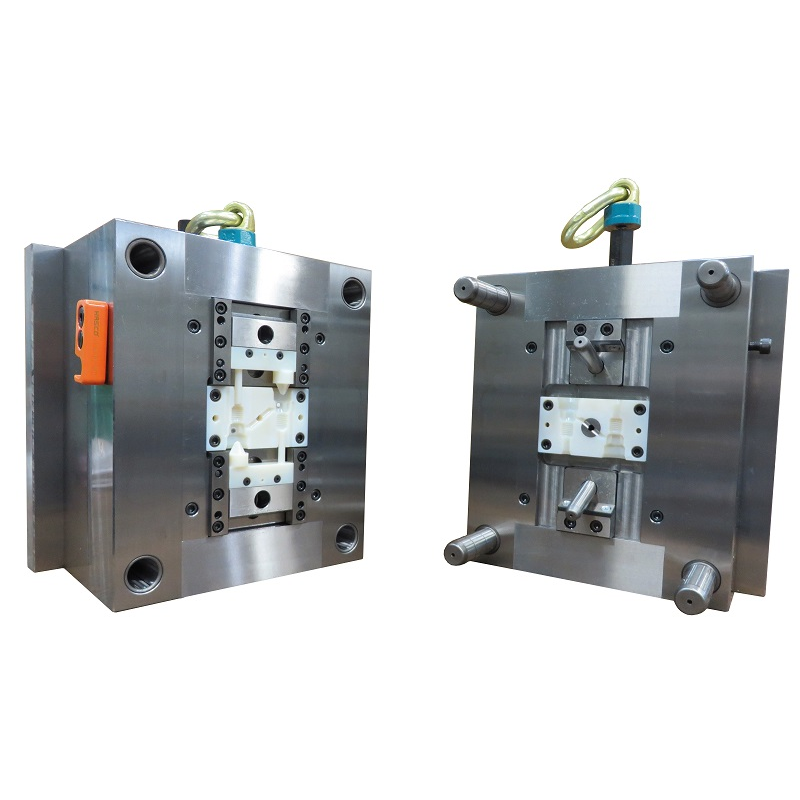

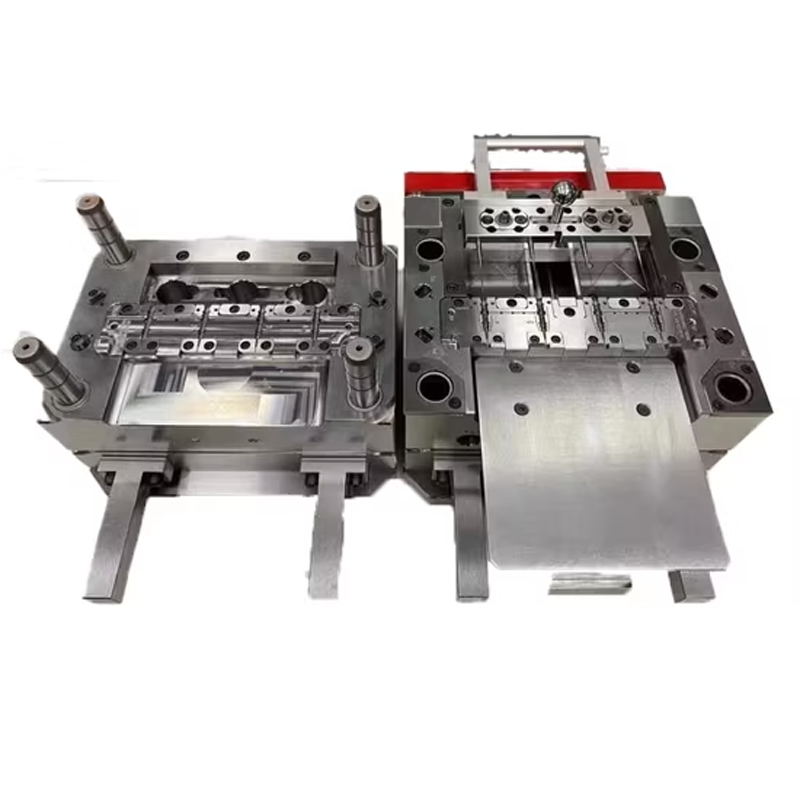

Aluminum Tooling:

On the other hand, aluminum molds can withstand thousands of shots, even with demanding materials like high-temperature plastics. In fact, aluminum molds can often produce well over 10,000 shots without significant degradation, making them much more reliable for large-scale manufacturing runs. This longer lifespan also means fewer costs related to mold replacements, making aluminum tooling a better option for mass production.

At LSRmold, our aluminum molds are designed to provide durability and longevity, ensuring that your parts are produced with consistent quality over time. We provide comprehensive DFM (Design for Manufacturing) services to ensure that the molds are optimized for both material performance and long-lasting production runs.

3. Cost and Speed

When comparing costs, 3D-printed molds may appear to be the more economical choice, especially for low-volume production runs. However, when considering the total cost of ownership—including labor, material costs, and the need for frequent mold replacements—the cost-effectiveness of 3D-printed molds diminishes.

3D-Printed Molds:

3D-printed molds are cheaper upfront, often costing only a fraction of the price of aluminum tooling. However, because they typically wear out after a limited number of shots, businesses may need to replace them frequently. Additionally, the post-processing required to fix surface imperfections can add to the overall cost.

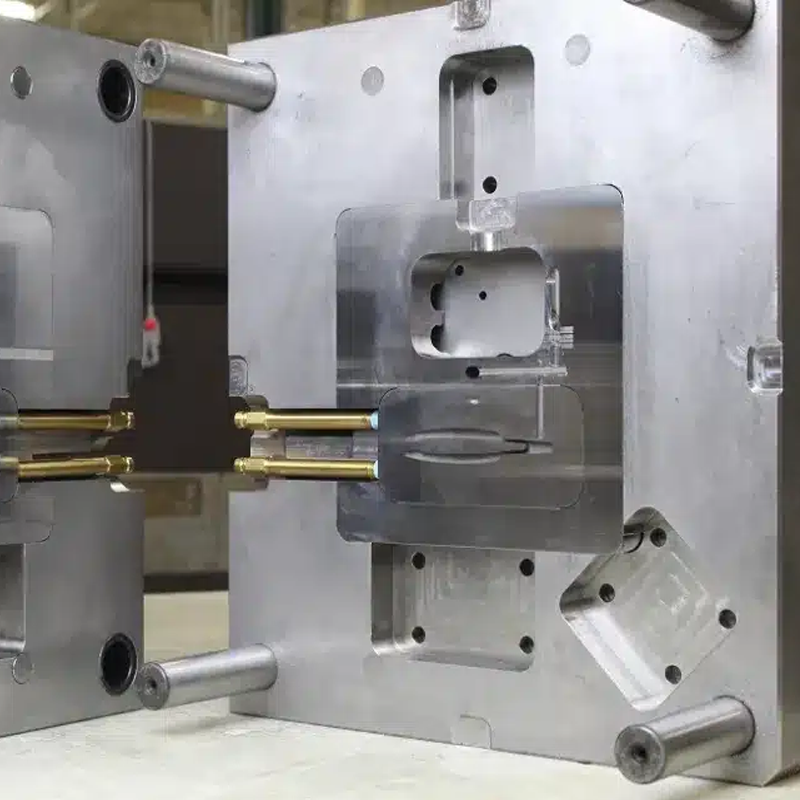

Aluminum Tooling:

Aluminum molds come with a higher initial price tag, but their durability and longevity make them a more cost-effective choice in the long run. Furthermore, aluminum molds can handle more complex geometries and are suitable for larger parts, which can provide further savings in terms of time and material costs.

At LSRmold, we offer custom services to help our clients choose the right molding option based on their project’s unique needs. We understand that each project has its own requirements and budget, so we work with you to determine the most cost-effective solution that meets your production goals.

4. Complexity of Part Design

Some designs are more complex than others, requiring molds that can accommodate intricate features. 3D-printed molds may struggle with very fine details or parts that require high precision in the cavity design.

3D-Printed Molds:

3D printing is well-suited for simple parts or prototypes but can struggle with producing parts that require complex geometries. The material flexibility of 3D printing may lead to some unwanted deformation, especially when parts are subjected to high injection pressures.

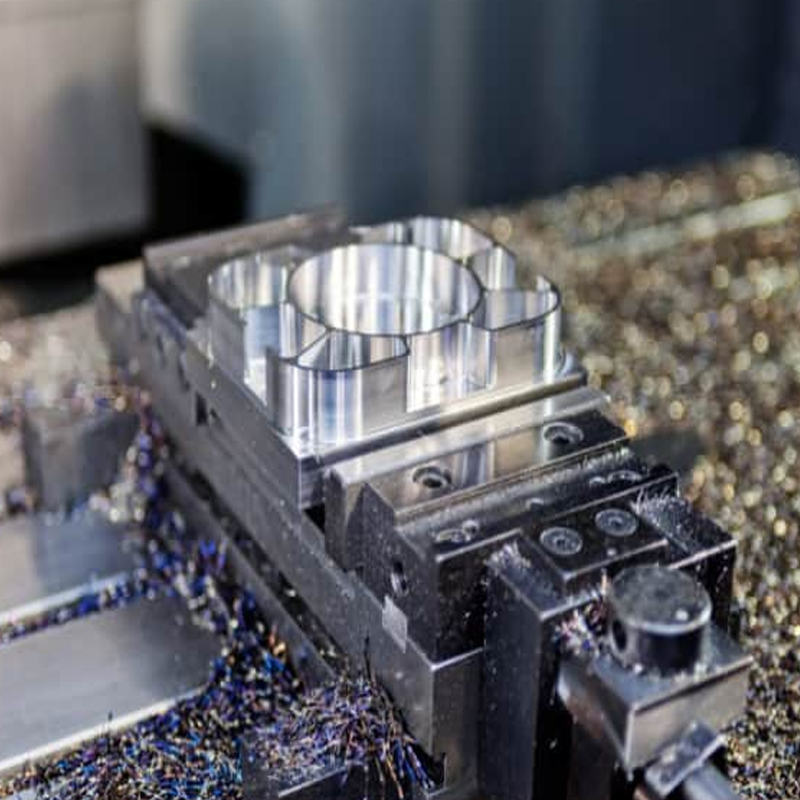

Aluminum Tooling:

Aluminum tooling, particularly when using CNC machining and EDM, can handle intricate designs, fine details, and tight tolerances with ease. Aluminum molds allow for precise control of the part cavities and can support features that are challenging for 3D printing to replicate.

At LSRmold, we take pride in our ability to manufacture complex injection molds that meet the highest standards of precision. Our team works closely with clients to understand the complexity of their part design and offer custom manufacturing solutions that achieve optimal results.

5. Design Flexibility and Adaptability

The flexibility of a mold design is important for projects that may require adjustments or adaptations over time.

3D-Printed Molds:

Since 3D-printed molds are relatively quick to produce, they offer more flexibility in the design process, especially for prototypes and low-volume runs. However, the mold’s design can be difficult to modify after production, and any design changes may require a new mold.

Aluminum Tooling:

While aluminum molds require a larger upfront investment, they offer greater adaptability for future design changes. With the right modifications, aluminum molds can be adjusted or repurposed for different product variations without needing a full replacement.

Conclusion

Choosing between 3D-printed molds and aluminum tooling ultimately depends on your production needs. If you need rapid prototyping or are working with low-volume runs, 3D-printed molds might be the best solution. However, for high-volume, high-precision applications, aluminum tooling is the preferred choice due to its durability, reliability, and cost-effectiveness over time.

At LSRmold, we provide both options to meet your specific requirements, with a focus on custom manufacturing solutions and one-stop service. Whether you need to prototype a new part or scale up production, we ensure that your molds are optimized for quality, efficiency, and cost savings.

If you’re ready to get started on your next injection molding project or need help deciding the right option for your manufacturing needs, contact us today. Let our team of experts guide you through the decision-making process and provide the support you need to bring your products to market with precision and reliability.