In today’s injection molding industry, the performance of your molds defines the consistency, accuracy, and long-term reliability of your production. If you are experiencing part defects, cycle time inconsistencies, or premature tooling wear, you’re not alone—these issues are common across the industry, especially as molds age or production volumes increase. At LSRmold, our team is dedicated to supporting manufacturers and suppliers who need dependable, high-quality, and cost-effective mold repair and modification services. If you’re searching for a factory partner that offers expert-level solutions with true custom service, we welcome you to discover how our capabilities can support your operational success.

For molders producing automotive, consumer goods, medical components, industrial parts, or specialty LSR products, mold maintenance is not simply a task—it’s an essential investment that directly influences product quality and operational efficiency. As a professional factory-level mold manufacturer, LSRmold understands that every customer depends on stable production, predictable results, and long service life of their tooling. That’s why we provide an end-to-end approach to mold repairs and modifications that prioritizes accuracy, transparency, and long-term tooling performance.

Why Mold Repairs and Modifications Are Essential for Modern Manufacturing

Injection molds endure high temperatures, continuous mechanical stress, and repetitive cycles. Even the most meticulously designed molds eventually require attention due to:

- Wear and tear of shut-offs and parting lines

- Cooling channel corrosion or blockage

- Degating or runner damage

- Design revisions or part updates

- Unexpected tooling crashes or material contamination

Ignoring early signs of damage not only leads to more costly repairs later—but also reduces product quality and increases scrap rates. LSRmold’s repair and modification services help our partners maintain production stability while prolonging mold life significantly.

LSRmold’s Complete Mold Repair & Modification Workflow

Our factory uses a structured, highly controlled process that ensures every mold—whether built by us or by other manufacturers—receives a high-precision evaluation and repair plan. This approach is part of our commitment to delivering consistently high-quality custom service.

Step 1: Issue Identification and Customer Communication

Every repair starts with clear and immediate communication.

When a customer reports part defects, flashing, dimensional inconsistencies, or operational issues, we begin by:

- Reviewing images, videos, or defect samples

- Documenting symptoms and suspected causes

- Providing an initial assessment and recommended next steps

For customers sending molds from other suppliers or factories, we request a brief tooling history and recent production notes. This allows us to create an accurate preliminary evaluation before the mold even arrives.

Our goal is to give every customer a fast, informed response so production interruptions remain minimal.

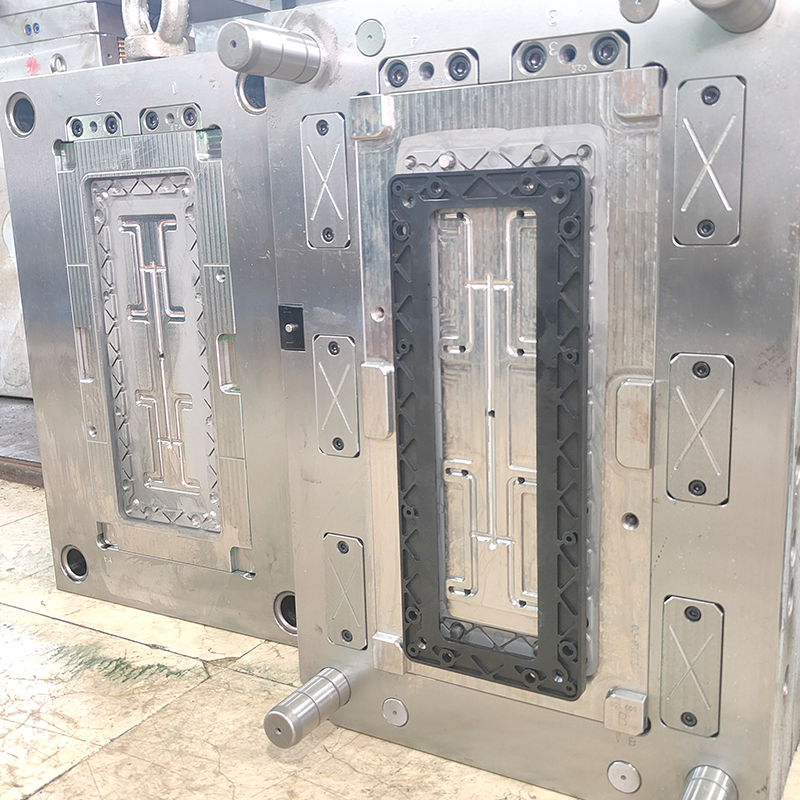

Step 2: Full Mold Disassembly and Root Cause Analysis

Once the mold arrives at our facility, our toolmakers perform a controlled teardown to inspect:

- Cores and cavities

- Slides, lifters, and inserts

- Ejector system

- Cooling lines and connectors

- Hot runner or cold runner components

- Venting, parting lines, and shut-offs

We evaluate not only the visible damage but also hidden underlying issues that often go unnoticed in standard inspections—such as internal corrosion, incorrect tolerances, dimensional drift, or misalignment caused by improper clamping or resin build-up.

Root cause analysis is the foundation of our high-quality repair strategy. Fixing symptoms alone is never acceptable at LSRmold—we address the true reason the mold failed.

Step 3: Detailed Repair Proposal & Transparent Costing

After diagnostic evaluation, LSRmold prepares a professional, easy-to-understand repair report that includes:

- A description of all problems found

- Recommended repair procedures

- Any components that require replacement

- Optional mold performance upgrades

- Accurate lead-time estimates

- Transparent pricing with no hidden charges

This step reinforces our commitment to open communication and factory-level accountability. Before we proceed, customers review and approve every detail, ensuring full alignment with production schedules and cost expectations.

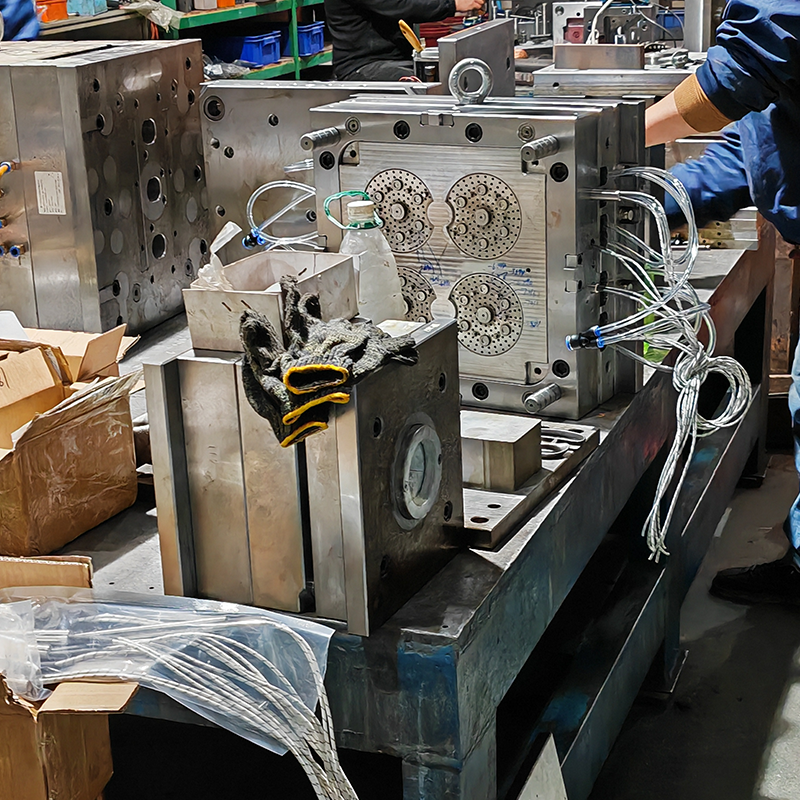

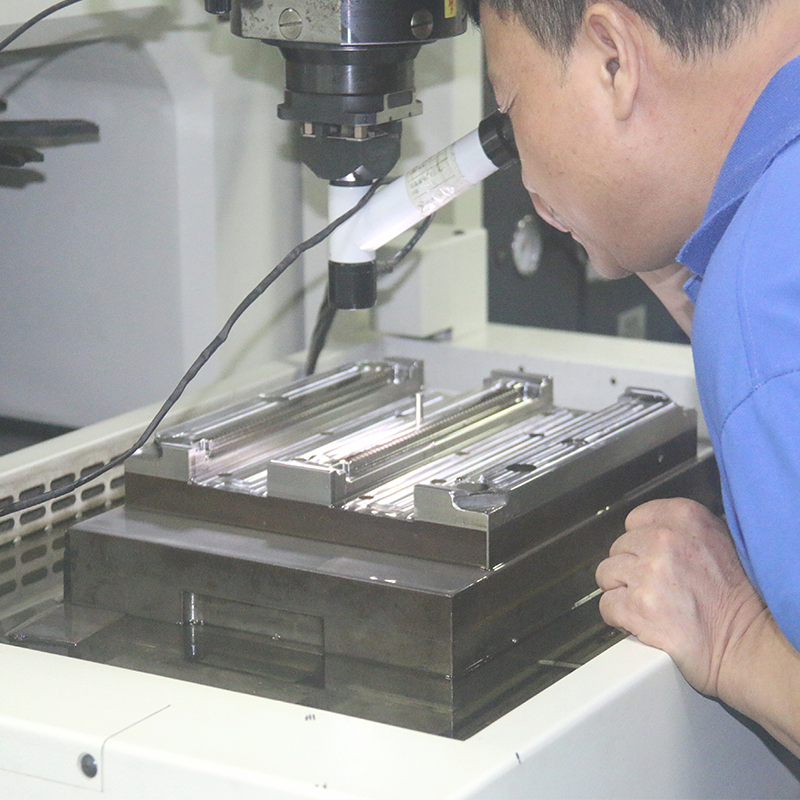

Step 4: Skilled Execution of Mold Repairs and Upgrades

Once approved, our technicians begin the repair using advanced equipment such as:

- High-precision CNC machining centers

- EDM and wire-cut EDM machines

- Laser welding and TIG welding stations

- Precision grinders and polishing systems

Typical repair and modification work includes:

- Reworking damaged shut-off surfaces

- Re-machining cores, cavities, and inserts

- Precision welding of worn or broken tooling features

- Restoring venting and parting lines

- Replacing gates, pins, bushings, or wear plates

- Cleaning and refinishing cavity surfaces

- Improving cooling channel performance

Every repair is executed to OEM-level standards—or higher. As a professional mold factory, LSRmold understands the critical tolerances required for consistent mass production.

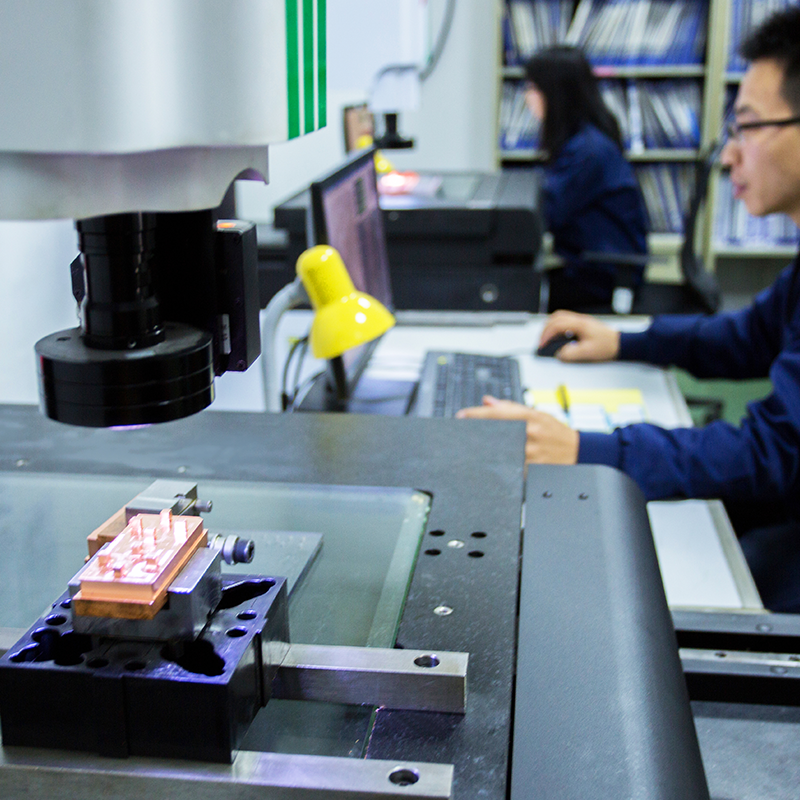

Step 5: Testing, Validation, and Quality Assurance

After repairs are completed, our factory performs:

- Dimensional checks

- Mold alignment and function testing

- Water channel pressure checks

- Ejector system verification

- Surface finish inspection

If required, we conduct trial molding to validate:

- Dimensional accuracy

- Cycle time stability

- Surface quality

- Part-to-part repeatability

Only after the mold meets our high-quality standards do we sign off for delivery back to the customer.

Frequently Asked Questions

1. How are repairs and modifications different from routine maintenance?

- Maintenance prevents damage by cleaning, lubricating, and adjusting components.

- Repairs fix actual wear or damage.

- Modifications alter tooling to meet new product requirements or improve performance.

2. What typically causes mold damage?

Common reasons include metal wear, high-volume cycles, poor cooling, misalignment, resin contamination, and inadequate maintenance. Even molds built by top manufacturers eventually require service.

3. How long does a repair typically take?

Timelines vary depending on complexity. LSRmold always provides a clear timeline estimate and maintains strong communication throughout the repair cycle.

4. Can LSRmold repair molds built by other suppliers?

Yes. We frequently receive molds from other factories—both domestic and international. Our team is experienced in repairing molds of all brands, designs, and complexities.

5. What types of molds can LSRmold handle?

We specialize in:

- Thermoplastic injection molds

- Liquid silicone rubber (LSR) molds

- Multi-cavity production molds

- Hot runner and cold runner tooling

- Large industrial and automotive molds

Why Manufacturers Choose LSRmold

As a professional factory and mold manufacturer, LSRmold stands out because of our:

Extensive Tooling Expertise

Our toolmakers bring decades of combined experience in mold building, repair, and optimization.

High-Quality Repair Standards

Every mold is restored to peak operational performance using advanced machinery and precise craftsmanship.

Custom Service for Every Customer

We tailor repair strategies, modification plans, and lead times based on your project needs, not generic templates.

Comprehensive In-House Equipment

We operate CNCs, EDMs, grinders, welding stations, and trial machines—all under one roof.

Reliable Support for Manufacturers & Suppliers

We understand downtime costs. Our rapid response and structured workflow help customers resume production faster.

Request a Mold Repair or Modification Quote Today

If your tooling is showing signs of wear, if part quality is declining, or if you need structural modifications for a new product design, LSRmold is ready to support you. Our factory team will analyze your mold, provide a transparent quotation, and deliver high-quality repair work that restores efficiency and extends mold lifespan.

Contact LSRmold today to request a consultation or obtain a custom repair quote.

We look forward to partnering with you and ensuring your production continues to run smoothly, efficiently, and without interruption.