Description:

We design and manufacture precision custom compression molding tooling for durable consumer electronics parts. Our molds produce high-quality silicone rubber components like seals, gaskets, and grips with exceptional consistency. We provide full OEM support from design to high-volume production.

Basic Information:

| Basic Information | Details |

|---|---|

| Mold Type | Precision Compression Molding Tooling |

| Mold Material Options | Pre-hardened Steel (P20, 718), H13, Stainless Steel |

| Mold Base Standards | Custom or Standard (LKM, DME) |

| Tooling Construction | Single/Multi-Cavity, Positive/Negative Molds |

| Design Software Supported | UG NX, SolidWorks, AutoCAD |

| Manufacturing Equipment Used | CNC Machining, EDM, Precision Grinding |

| Compatible Raw Materials | Silicone Rubber (HCR), TPE, Fluorosilicone, EPDM |

| Part Complexity | Medium to High (with integrated inserts, undercuts) |

| Packaging Method | Reinforced Wooden Case |

| OEM Services | Supported (Provide 3D models/samples) |

| Lead Time (T1 Sample) | 30-45 days |

Advantages of Our Molds:

-

Exceptional Durability for High-Volume Runs: Engineered from premium tool steels to withstand repeated high-temperature and high-pressure cycles, ensuring long service life and consistent part quality.

-

High Precision for Complex Part Geometries: Advanced machining and finishing techniques achieve tight tolerances and fine details, critical for intricate seals, buttons, and multi-material components in electronics.

-

Optimized for Efficient Production & Easy Maintenance: Designed with efficient cooling channels and robust ejection systems to minimize cycle time. Modular design simplifies maintenance and repair, reducing downtime.

-

Superior Surface Finish & Part Release: Precision-polished cavities and advanced surface treatments ensure flawless part surfaces and easy, consistent demolding, reducing waste and secondary operations.

Surface Coating Options:

-

PTFE (Teflon) Impregnated Coating: Reduces surface friction significantly, facilitating the release of sticky elastomers like silicone and preventing material buildup for faster cycles.

-

Hard Chrome Plating: Provides excellent corrosion resistance and a very hard, durable surface that resists abrasion from filled rubber compounds.

-

Nickel-PTFE Composite Coating: Combines the durability of electroless nickel with the non-stick properties of PTFE, offering superior release and extended mold life for high-volume production.

-

Titanium Nitride (TiN) Coating (PVD): A hard, wear-resistant coating ideal for molds producing parts with abrasive fillers, protecting critical edges and surfaces from premature wear.

Production Process:

-

Design & DFM Analysis: Our engineers analyze your 3D part model for moldability, suggest design optimizations for compression molding, and create the mold design.

-

Material Selection & Mold Fabrication: Select the appropriate mold steel. Utilize CNC machining, EDM, and deep-hole drilling to create the precision cavities, cores, and cooling channels.

-

Mold Assembly & Fitting: All components, including guide pillars, ejection system, and heating/cooling lines, are meticulously assembled and fitted for smooth operation.

-

Trial Molding & Sample Validation (T1): The mold is installed in a compression press to produce first articles. Parts are evaluated for dimensions, flash, and material cure.

-

Mold Fine-Tuning & Approval: Based on T1 results, adjustments are made (e.g., venting, land area). Approved samples are sent to the customer.

-

Final Surface Treatment & Documentation: The approved mold receives the specified surface coating. Final documentation, including mold drawings and maintenance guides, is prepared.

-

Production Release & Support: The mold is released for mass production, with ongoing technical support available.

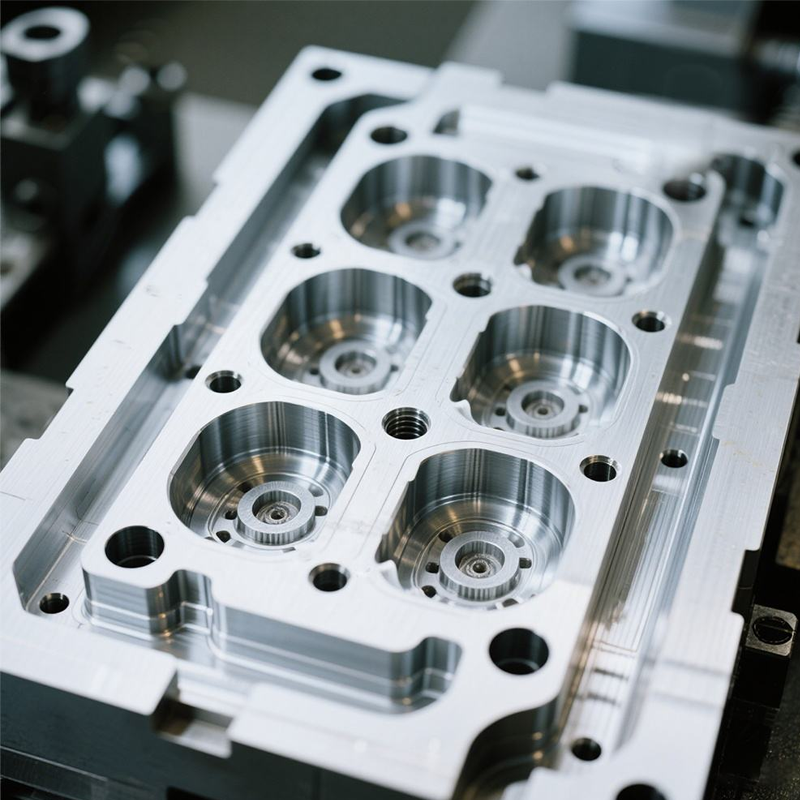

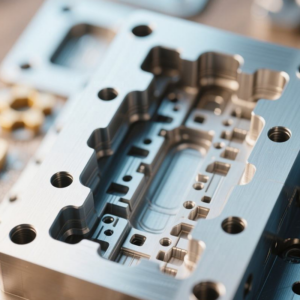

Factory Show:

Our manufacturing hub is equipped with a dedicated tool room featuring state-of-the-art CNC machining centers, wire EDM, and sinker EDM for crafting high-precision compression molds. We operate multiple compression molding presses of various tonnages for mold testing and validation. Our quality assurance is supported by CMMs for dimensional verification and advanced polishing stations for achieving required surface finishes. This integrated capability ensures we deliver robust, reliable tooling capable of producing the consistent, high-quality rubber components demanded by the consumer electronics industry.