Overview

Our Personalized Plastic Injection Molding Mold Tooling for Electronics Parts & Household Products — China delivers precision, repeatability, and fast time-to-market for consumer electronics, small appliances, connectors, enclosures, switches, and other household components. Custom-designed per part geometry and production volume, these molds combine optimized hot-runner or cold-runner systems, balanced cooling, and precision cavity machining to ensure consistent part quality, short cycle times, and long tool life.

Basic Information

| Specification | Details |

|---|---|

| Material Options | P20, H13, S136, NAK80, Aluminum 7075 (prototype) |

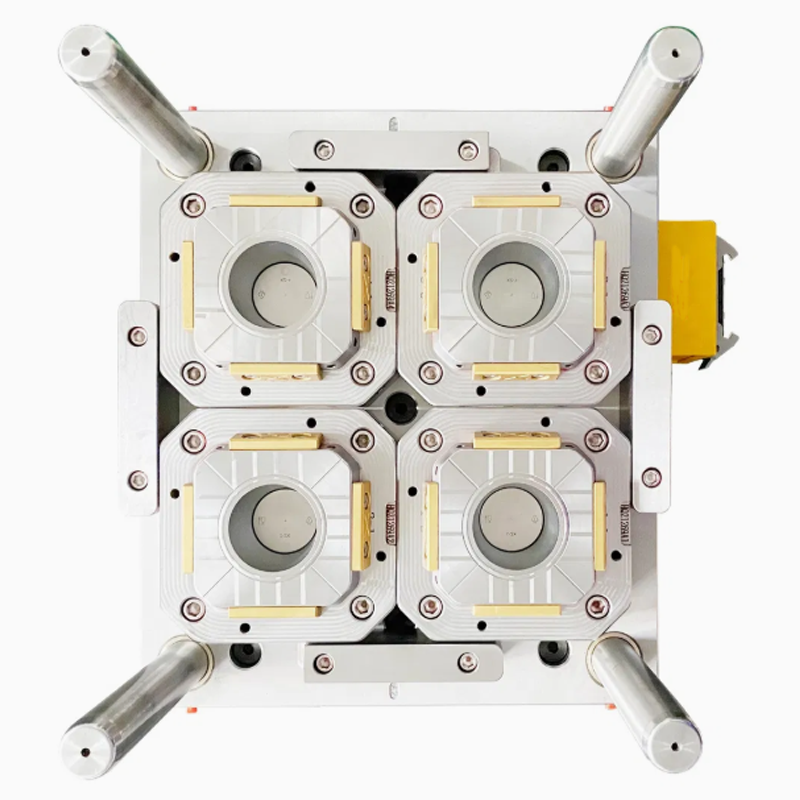

| Mold Type | Single / Multi-cavity, Family molds, Insert molds, Stack molds |

| Core Processes | 5-axis CNC machining, Mirror EDM, Wire EDM, High-speed milling, Precision grinding |

| Surface Finish | Polished / textured cavities (typical Ra ≤ 0.8 µm; optical parts Ra ≤ 0.2 µm) |

| Runner System | Hot runner (valve gate optional) or Cold runner — custom per part & cycle |

| Typical Tolerance | ±0.01 mm (standard); ±0.005 mm achievable for critical features |

| Lead Time | Prototype tooling: 15–25 days; Production tooling: 3–6 weeks (depends on complexity) |

| Compatible Materials | ABS, PC, PC/ABS, POM, PA6/PA66, PP, PET, LCP, TPU |

| Cavity Count | Single to high-cavity (designed for balanced filling & consistent cooling) |

| Tooling Life | 100,000 → 1,000,000+ shots (steel grade & coating dependent) |

| Certifications | ISO 9001, IATF 16949, RoHS / CE support available |

| Origin | Xiamen, China — full OEM service & export packaging |

Key Advantages

- Precision & Repeatability: Tight tolerances and consistent part weights through CNC + EDM-finished cavities.

- Optimized Cycle Efficiency: Advanced cooling channel layouts and hot-runner design reduce cycle time and part deformation.

- Surface & Cosmetic Control: Mirror polishing and SPI texturing to meet aesthetic and tactile requirements for consumer-facing parts.

- Scalable Production: From rapid prototype aluminum tools to hardened steel multi-cavity production molds.

- Full OEM Service: DFM review, Moldflow simulation, pilot runs, and production ramp support — single-source solution from CAD to shipment.

Surface Treatment & Finishing Options

- Mirror Polishing / SPI A1: For gloss optical surfaces and cosmetics.

- Texturing (MT / SPI): Anti-fingerprint, matte, or custom textures.

- Hard Chrome Plating: Longer life, improved release for abrasive resins.

- Nitriding / Case Hardening: Increased surface hardness and wear resistance.

- PVD / DLC Coatings: Low friction and anti-adhesion for specialty polymers.

- Electropolish & Passivation: Corrosion resistance for stainless tool components.

Quality Assurance

We implement end-to-end QA: incoming steel certification, in-process dimensional control, final CMM verification, and first-article sample reports. Tools are validated with trial shots and full part testing (shrinkage, dimensional stability, mechanical fit). Moldflow and CAE are used during design to predict filling, warpage, and cooling performance. All documentation (material certificates, trial data, maintenance guides) is supplied for traceability.

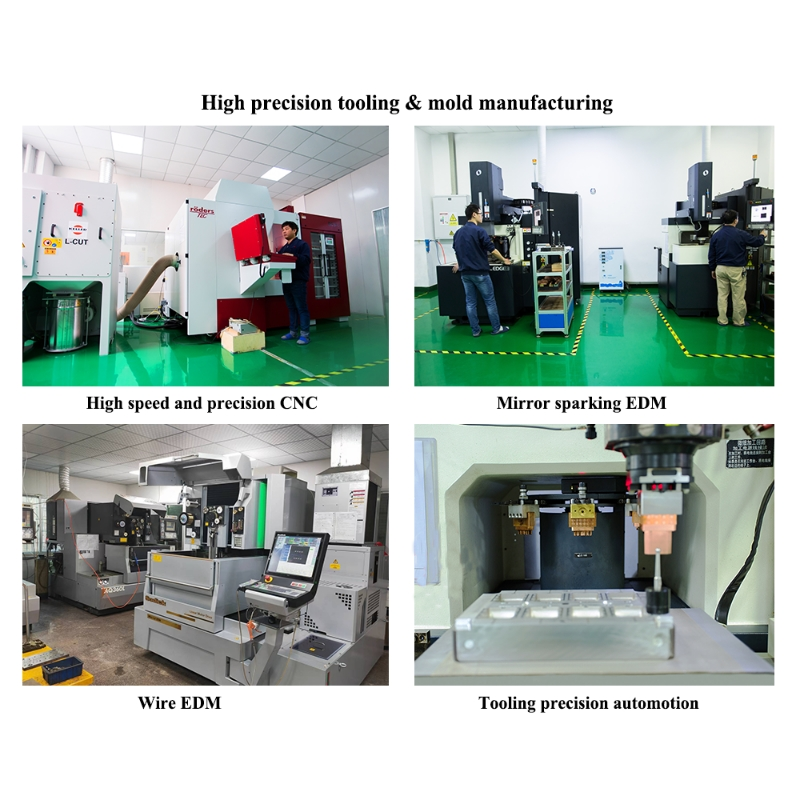

Our Factory

Our tooling shop integrates high-speed 5-axis CNC centers, mirror EDM, precision wire EDM, and automated polishing stations to guarantee cavity accuracy and surface quality. We run in-house heat treatment, coating, and assembly lines, and validate molds on programmable press benches with hot-runner tuning and sample runs. Backed by ISO 9001 and IATF procedures, our engineering team provides DFM, rapid prototyping (aluminum molds), pilot validation, and production ramp support to meet global OEM requirements.