Overview:

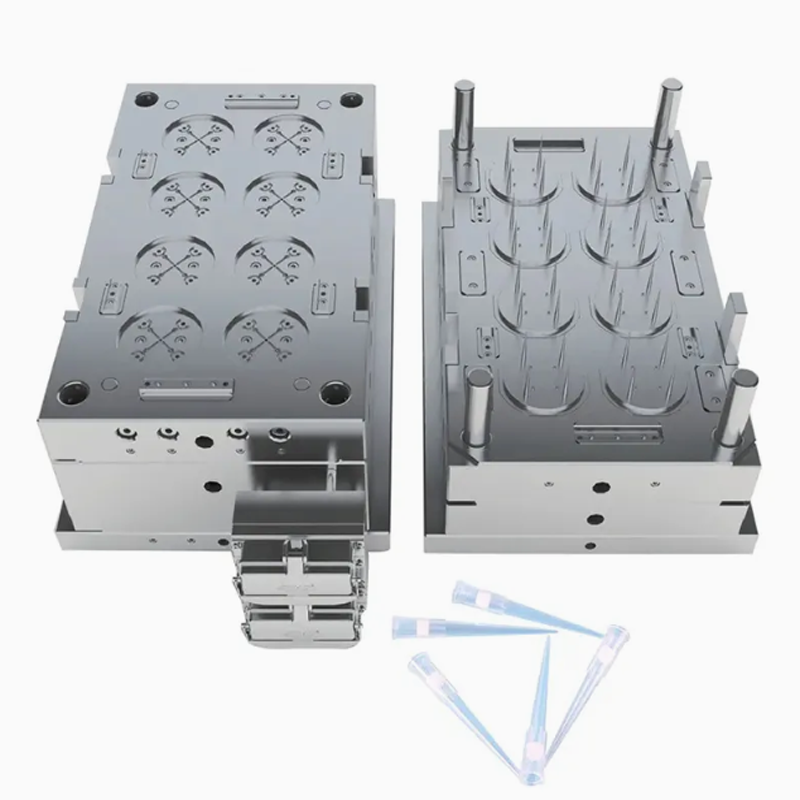

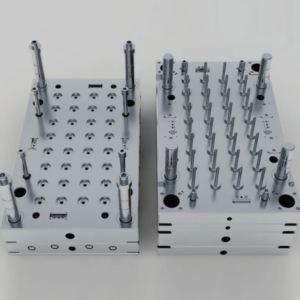

Our Personalized High Standard Stainless Steel Precision Medical Injection Tooling Moulds are designed for the manufacturing of high-precision medical-grade parts. These molds are constructed using premium stainless steel to ensure the utmost durability, resistance to wear, and compliance with strict medical industry standards. Engineered through advanced CNC machining and EDM (Electrical Discharge Machining) techniques, these molds provide unmatched precision and operational efficiency, making them ideal for producing a wide range of medical components. With a strong focus on custom-tailored solutions, we offer molds that meet your specific requirements, ensuring optimal performance in medical applications that demand the highest quality and reliability. We provide a complete range of services, from mold design to production, to ensure your parts are produced to the highest standards, in line with ISO 13485 and other industry certifications.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Stainless Steel |

| Runner System | Hot/Cold Runner |

| Mould Design Software | UG, PROE, SOLIDWORKS, CAD |

| Sample | Available |

| Certification | ISO 9001, IATF 16949, ISO 13485 |

| Packaging | Custom |

| MOQ | According to your requirement |

| Lead Time | 30-35 days |

Why Partner with Us?

- Precision Engineering: Utilizing advanced CNC machining and EDM technologies for high-precision manufacturing, ensuring tight tolerances and perfect part replication.

- High-Quality Materials: Made from durable stainless steel, ensuring longevity, high strength, and resistance to wear and tear.

- Customization: We provide personalized solutions to meet the exact design specifications of different types of medical parts.

- Cost-Effective Manufacturing: With optimized tooling designs, we provide affordable solutions for both large-scale and low-volume production.

- Rigorous Quality Assurance: Stringent quality control at every stage of production to ensure compliance with industry standards.

Surface Treatment Options:

- Nickel Plating:

Offers excellent corrosion resistance and enhances mold durability, making it ideal for medical-grade applications that demand high standards of hygiene and long-term performance. - Hard Anodizing:

Increases surface hardness, wear resistance, and ensures the mold maintains precision and longevity, even after repeated use in injection molding processes. - Chromium Plating:

Provides a hard, smooth finish that prevents wear and corrosion, ensuring molds maintain optimal performance and longevity in the most demanding medical applications. - Polishing:

Improves surface finish and reduces friction during the molding process, enhancing the quality of molded parts and ensuring easy removal from the mold without compromising integrity.

Manufacturing Process:

- Material Selection & Preparation:

We begin by sourcing the finest stainless steel materials that meet stringent industry standards. Materials are carefully selected to ensure resistance to corrosion and wear, critical for medical-grade components. - Tooling & Die Design:

We use cutting-edge software such as UG, PROE, SOLIDWORKS, and CAD to design customized tooling and molds. The design ensures the molds meet your precise specifications, offering flexibility for various types of medical parts. - CNC Machining & EDM:

Utilizing CNC machining, we achieve high precision in mold components, followed by EDM for intricate, detailed features. This combination allows us to achieve tight tolerances, high-quality finishes, and complex geometries that are essential for medical parts. - Injection Molding:

Once the molds are ready, they are used in precision injection molding to create medical-grade components. This process ensures uniformity and accuracy in the final parts. - Inspection & Testing:

We employ high-precision inspection tools such as coordinate measuring machines (CMM), hardness testers, surface roughness analyzers, and electrical conductivity testers to verify that each mold meets the exact standards. The molds undergo rigorous testing for accuracy, material integrity, and overall performance. - Final Assembly & Packaging:

After successful molding and inspection, the molds are assembled and packaged securely for shipment, ensuring they reach you in perfect condition, ready for use in the manufacturing of medical parts.

Quality Assurance:

Our Personalized High Standard Stainless Steel Precision Medical Injection Tooling Molds are manufactured under a robust quality management system, fully compliant with ISO 9001 and IATF 16949 certifications, and adhering to ISO 13485 to meet the stringent standards required for medical device manufacturing. To ensure superior performance and reliability, our experienced quality control team utilizes advanced testing equipment throughout the production process. This includes Coordinate Measuring Machines (CMM) for precise dimensional checks, hardness testers to assess material properties, surface roughness analyzers to inspect mold finishes, and conductivity testers to verify electrical conductivity for medical components that require it. These measures ensure that our molds consistently meet the highest quality standards for medical applications.

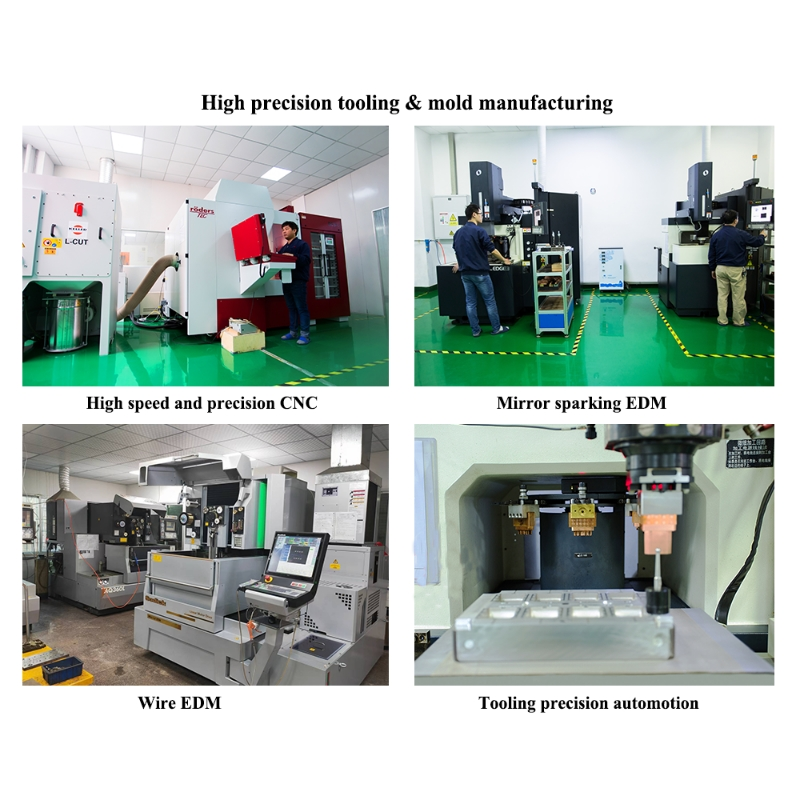

Factory Show:

Our advanced manufacturing facility is equipped with state-of-the-art technologies to ensure precision and high-quality mold production. CNC Machining Centers enable precision milling of mold components, achieving tight tolerances and superior quality. Our EDM Stations, featuring both mirror-finish and conventional EDM capabilities, are utilized to create complex mold cavities and intricate features that traditional machining methods cannot achieve. For complex geometries, we rely on precision wire cutting systems, delivering high-precision cuts for intricate designs.

In addition to these technologies, our facility is equipped with rubber compression molding and LSR injection molding machines, allowing us to scale production while maintaining tight tolerances and consistent results. We also incorporate automated systems, such as AutoDryers, high-speed doming machines, and precision die-cutting equipment, to enhance operational efficiency and ensure high productivity, all while upholding rigorous quality standards.