Custom Mold Display

Here are molds spanning various industries, each meticulously designed and manufactured with rigorous processes. Additionally, we offer comprehensive customization services, ensuring that no matter your industry, we can tailor a mold to meet your specific needs.

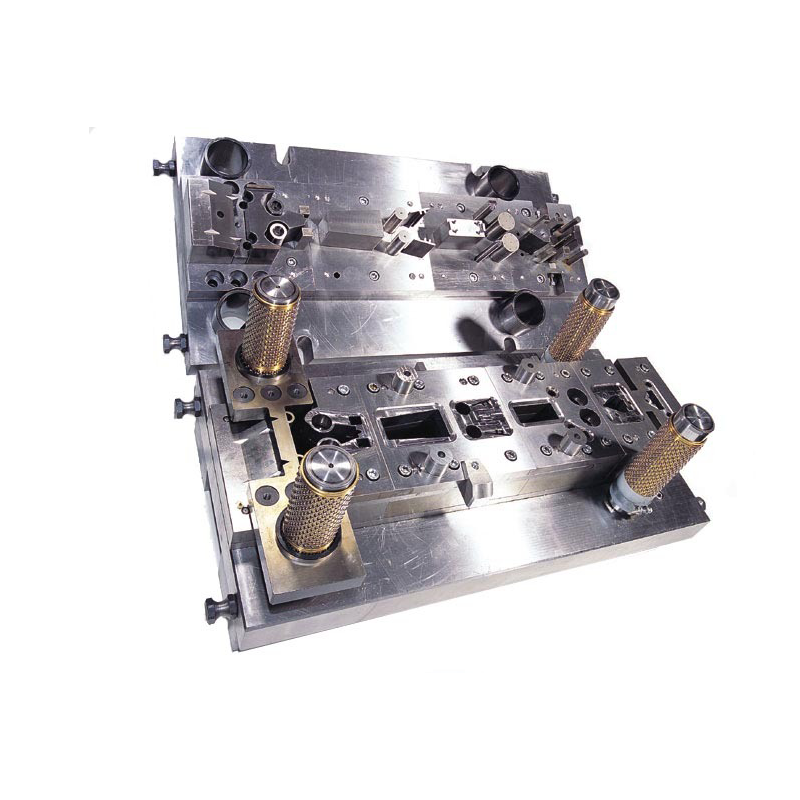

Tool Die and Mould Making is a precision manufacturing process used to create custom tools, dies, and molds for producing high-quality parts in industries like automotive, consumer goods, and electronics. This process involves designing and fabricating tools that can shape, cut, or form materials such as metal, plastic, or rubber. With advanced techniques like CNC […]

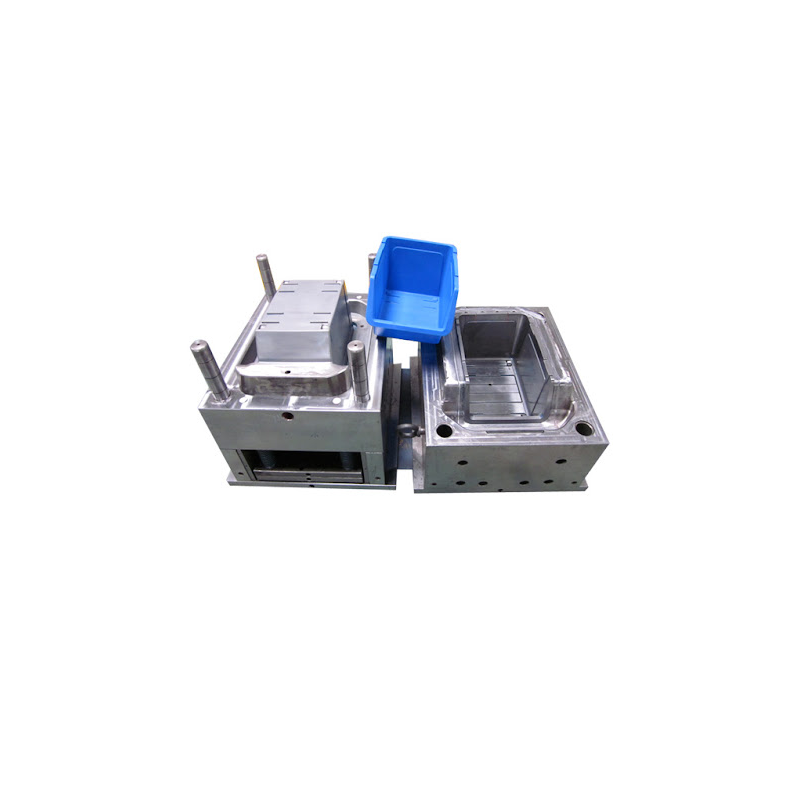

Tool box mould is a custom-designed mold used to manufacture durable and functional tool boxes, typically made from plastic or other sturdy materials. This mould is engineered to shape and form the tool box into its desired size and design, ensuring precise dimensions, smooth finishes, and strong structural integrity. Tool box moulds are widely used […]

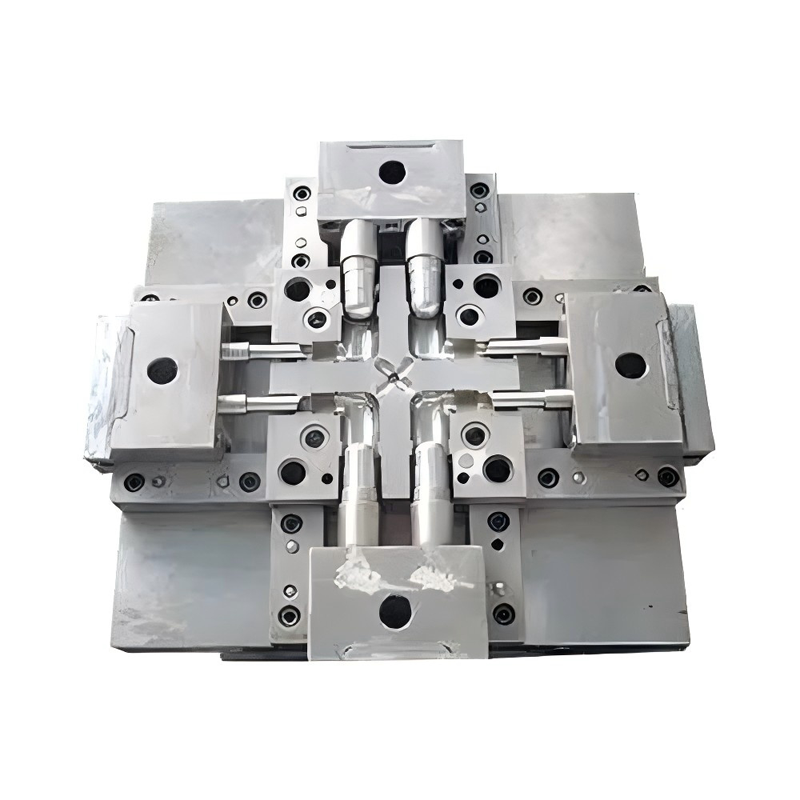

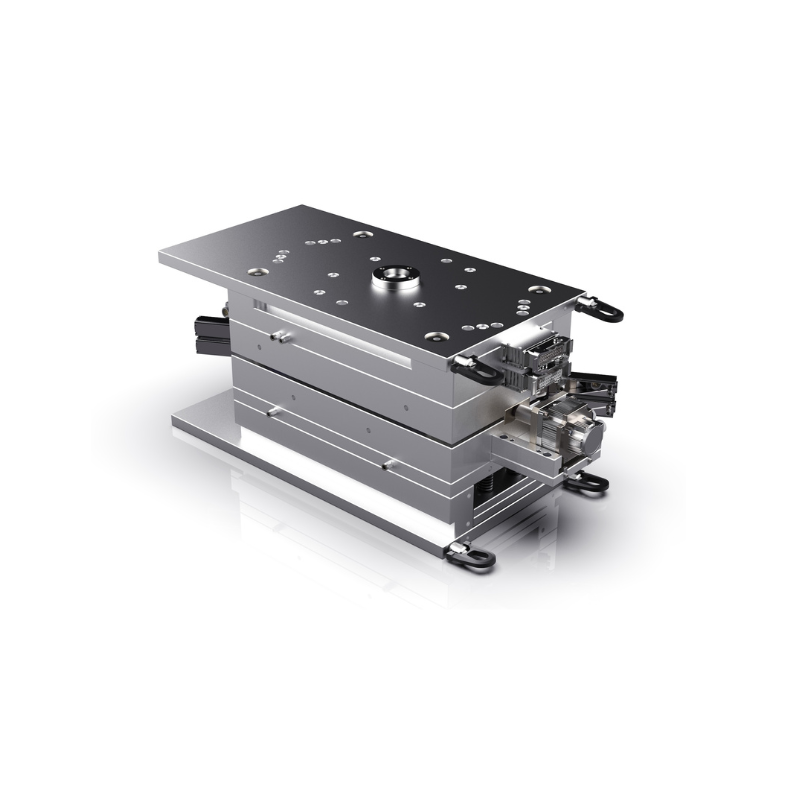

Prototype mould tools in London are specialized tools used to create prototype plastic parts quickly and cost-effectively, typically for product testing or design validation. These moulds are often made from softer materials, such as aluminium, to reduce production time and cost compared to traditional steel moulds. Prototype moulding allows companies to produce low to medium […]

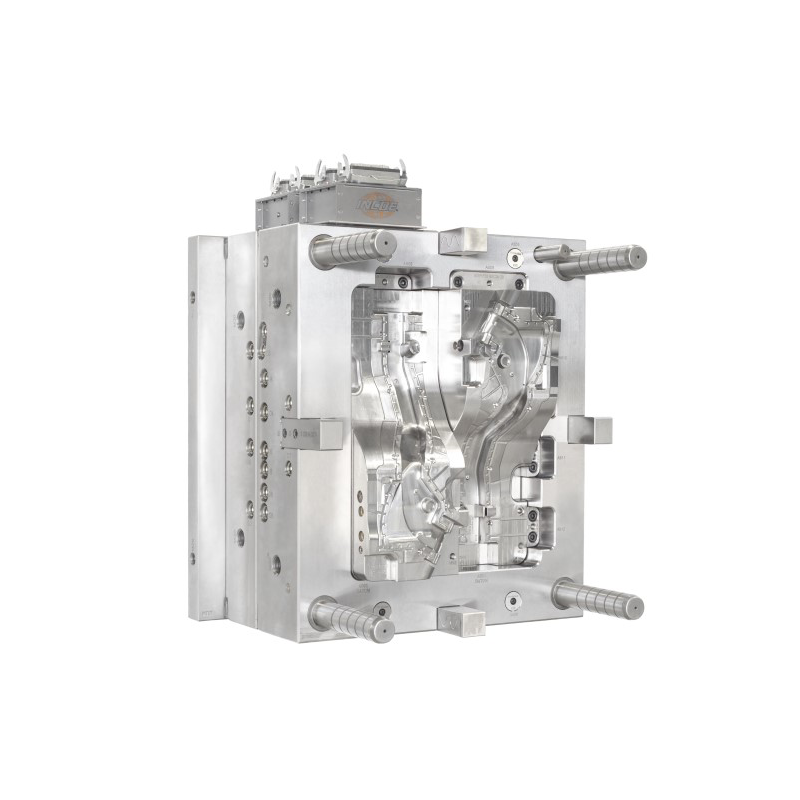

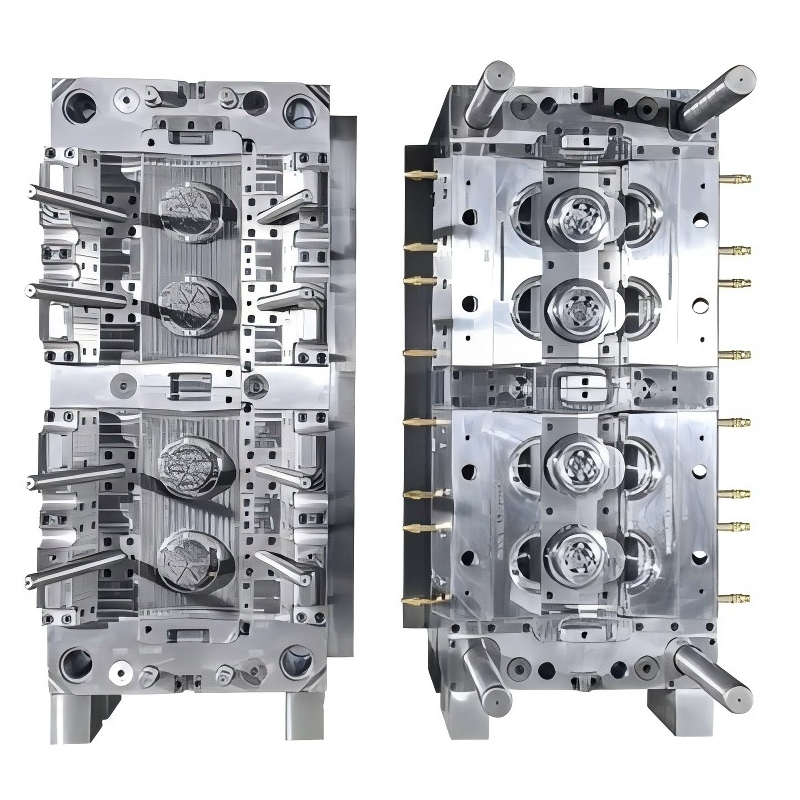

A plastic mold tool is a custom-designed mold used in the plastic injection molding process to manufacture plastic parts in high volumes. Made from strong materials like hardened steel or aluminum, the mold tool contains one or more cavities that shape molten plastic into the precise geometry required for each part. The tool is designed […]

Form molds and tooling are essential components in various manufacturing processes, specifically designed to shape materials into precise forms for a wide range of products. Form molds refer to the physical cavity or structure into which raw material, such as plastic, metal, or rubber, is introduced to be shaped. These molds are engineered to reflect […]

Injection mold tooling is the process of creating molds used in injection molding to mass-produce complex plastic parts with high precision and consistency. This involves designing and fabricating steel or aluminum molds that can withstand the high pressures and temperatures involved in injection molding. The tooling process uses advanced techniques such as CNC machining, EDM […]

Molding tools are critical components in the manufacturing process, shaping materials such as plastic, metal, and rubber into precise forms. These tools encompass a range of equipment, including injection molds, compression molds, blow molds, and extrusion dies, each suited for specific molding methods. Typically made from durable materials like hardened steel or aluminum, molding tools […]

Producing Automobile Parts Molds entails crafting highly precise molds for a variety of vehicle components, including bumpers, dashboards, engine covers, and interior trims. These molds play a critical role in providing structural integrity and functionality for automotive assemblies. Constructed from durable materials and designed to meet rigorous industry standards, these molds are built to endure […]

Our furniture molds are expertly crafted to meet the diverse demands of modern furniture manufacturing, designed for precision, durability, and flexibility in producing high-quality components. Utilizing advanced molding technologies, our molds can be customized for various furniture parts, including chair backs, armrests, table bases, and intricate decorative elements. Built with robust materials and engineered for […]

A storage box mould is a specialized injection mold designed for manufacturing plastic storage boxes used in homes, offices, warehouses, and more. Crafted from high-grade steel, the mould is built for durability and high-volume production, ensuring that each storage box produced has precise dimensions, a smooth finish, and excellent durability. It can be customized to […]