Overview

The OEM High Precision Overmolding Two-Shot Injection Moulding Tooling Mold is engineered for manufacturing complex silicone-and-plastic composite parts with unmatched accuracy and efficiency. Constructed from premium tool steels (e.g., H13, S136) and utilizing advanced technologies like CNC machining, EDM, and conformal cooling, this mold enables seamless multi-material bonding for applications requiring superior sealing, ergonomics, and durability. As an IATF 16949-certified manufacturer, we provide end-to-end custom solutions—from design optimization to high-volume production—ensuring compliance with automotive, medical, and consumer electronics standards.

![]()

![]()

Characteristics

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Product Material | Tool Steel (H13/S136), Aluminum (prototypes) |

| Runner System | Hot Runner (primary), Cold Runner (secondary) |

| Mould Design Software | UG NX, SOLIDWORKS, AutoCAD, Moldflow |

| Sample | Available (functional overmolded parts) |

| Certification | ISO 9001, IATF 16949, ISO 13485 (medical) |

| Packaging | Custom wooden crates, anti-rust protection |

| MOQ | 1 set (volume production supported) |

| Lead Time | 30–35 days (includes DFM and prototyping) |

Benefits of Our Mold Tooling

-

Dual-Material Precision: CNC-machined cavities (±0.01mm tolerance) and EDM-finished surfaces (Ra ≤0.1μm) ensure perfect alignment between silicone and plastic components, eliminating flash or bonding defects.

-

Enhanced Productivity: Conformal cooling channels and optimized runner systems reduce cycle times by 25%, while rotary platens enable seamless two-shot injection for high-volume orders (500k+ cycles).

-

Surface Excellence: Mirror polishing (VDI 3400 #A1) and textured finishes (e.g., MT-11000) minimize part ejection issues and post-processing, delivering ready-to-use overmolded parts.

-

Durability & Maintenance: Hardened tool steels with PVD coatings (e.g., TiN) extend mold life to 1M+ cycles, supported by predictive maintenance protocols for minimal downtime.

Surface Treatment Options

-

PVD Coating (TiN/CrN): Enhances wear resistance and reduces friction for silicone injection.

-

Nitriding: Increases surface hardness (≥1,000 HV) for prolonged durability against abrasive materials.

-

Electropolishing: Improves corrosion resistance and facilitates demolding of sticky silicone parts.

-

Laser Texturing: Creates custom surface patterns (e.g., grip textures) for ergonomic part designs.

Quality Assurance

Our quality assurance process adheres to IATF 16949 and ISO 13485 standards, integrating rigorous checks from design to delivery. We perform DFM analysis to prevent defects, use CMMs (±0.005mm) for cavity/core alignment validation, and conduct trial runs with actual materials (silicone/plastic) to verify bonding strength and dimensional accuracy. Advanced tools like 3D scanners (for part geometry) and pressure sensors (for injection monitoring) ensure consistency, while material certifications (USP Class VI, UL94) guarantee compliance for critical industries.

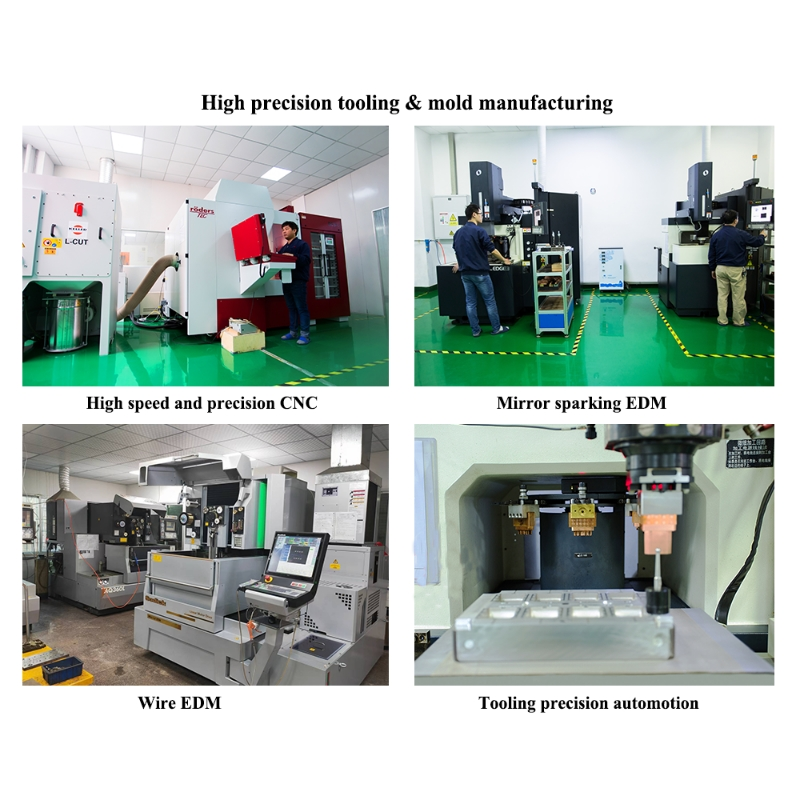

Factory Show

Our facility features 5-axis CNC machines (±0.002mm accuracy), mirror EDM for intricate geometries, and automated robotic systems for mold assembly and testing. With 15 injection molding machines (50–500 tons) and 2 two-shot rotary presses, we support complex overmolding production. Quality is enforced through Zeiss CMMs, Moldflow simulation software, and cleanroom environments for medical-grade parts. Automation solutions like auto-dryers and vision inspection systems ensure efficiency and defect-free outputs, aligning with global standards for automotive and medical applications.