Overview:

A Customized Plastic Baby Bathtub Mold Tooling is a precision-engineered system designed for manufacturing safe, ergonomic infant bathtubs via injection molding. Crafted from high-grade materials like pre-hardened steel, stainless steel, or aluminum alloys, these molds undergo advanced processes including CNC machining, EDM (Electrical Discharge Machining), and mirror polishing to ensure flawless surface finishes and dimensional accuracy. Our factory specializes in OEM and fully custom mold tooling services, offering end-to-end support from design to production. Equipped with state-of-the-art technology, we deliver durable, FDA-compliant molds optimized for high-volume efficiency or small-batch flexibility. Trust our expertise to create tailored solutions that meet your exact specifications, ensuring superior product quality and faster time-to-market.

Basic Information:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Product Material | Plastic |

| Certification | ISO, FDA |

| Cavity | Custom |

| Design | 2D or 3D |

| Runner Type | Cold runner |

| Mould Steel | P20H / 718 / 2316 / 2738, etc. |

| Mould Life | 500,000–1,000,000 shots |

| Sample Time | 45–60 days |

Surface Coating Options:

- Hard Chrome Plating:Provides a highly wear-resistant, low-friction surface that extends mold life and eases part release.

- Electroless Nickel Plating:Offers uniform corrosion protection and excellent hardness, even in complex cavity geometries.

- PVD Titanium Nitride (TiN) Coating:Delivers superior abrasion resistance and thermal stability, reducing cycle times and maintenance.

- Diamond-Like Carbon (DLC) Coating:Combines ultra-low friction with exceptional hardness for maximum durability and flawless surface finish.

Quality Assurance:

Our QA process ensures precision and compliance through rigorous material testing (XRF spectrometers), dimensional verification (CMM machines), and durability assessments (pressure/cycle testing). Molds undergo surface finish inspection (3D profilometers) and tolerance checks (±0.01mm accuracy) to meet ASTM, ISO, and FDA standards. Certified under ISO 9001 and IATF 16949, we utilize advanced equipment like CT scanners and Rockwell hardness testers to validate mold integrity and performance. Every tool is documented with full traceability, ensuring safety, functionality, and compliance for infant products.

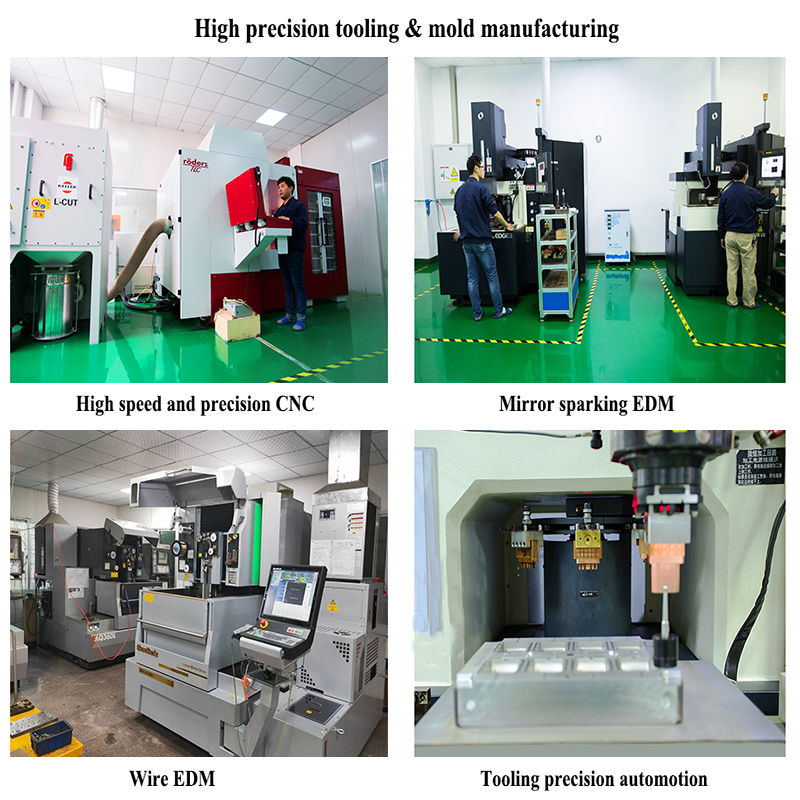

Our Factory:

Our state-of-the-art manufacturing campus is equipped with leading-edge CNC machining centers, mirror EDM, conventional EDM, and ultra-precise wire-cutting systems to ensure exceptional mold accuracy, consistency, and repeatability. On the molding floor, fifteen rubber compression presses and two high-speed liquid silicone rubber (LSR) injection machines support large-volume production and complex custom tooling projects, delivering rapid cycle times and tight tolerances. Quality assurance permeates every phase under our ISO 9001 and IATF 16949 certifications: seasoned QC engineers employ 3D optical projectors, sealing-integrity testers, Shore durometers, and elasticity gauges for rigorous inspections, while automated AutoDryers, high-throughput doming stations, and precision die-cutters streamline process uniformity. This integrated approach guarantees performance-critical components that consistently surpass the highest industry standards.