Overview:

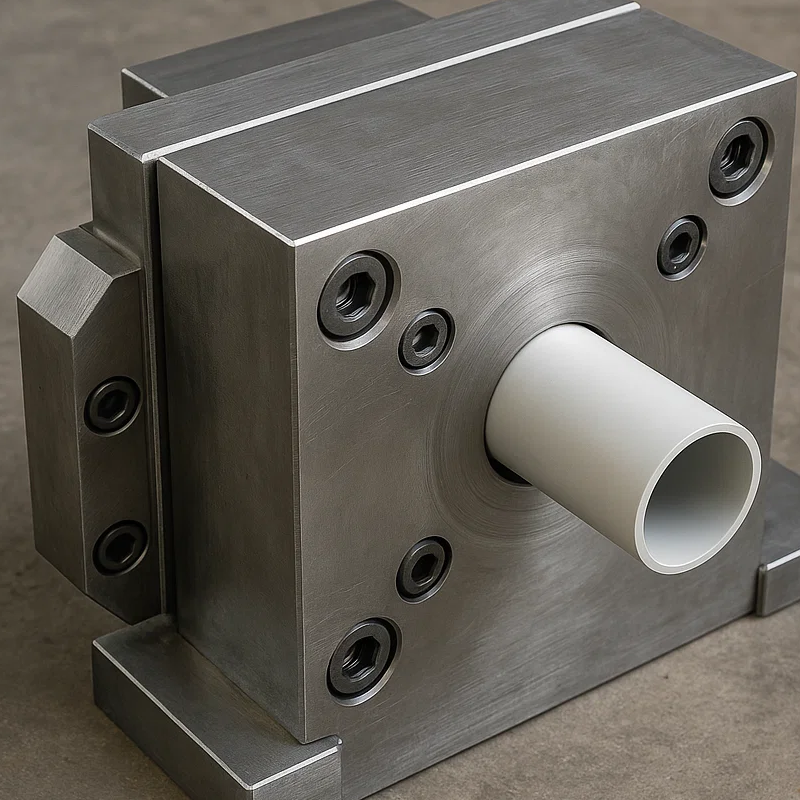

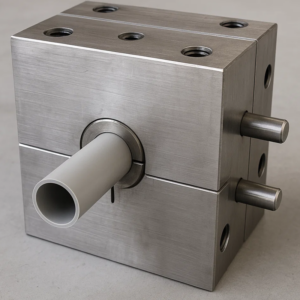

The Customized P20 Extrusion Die Molding Tooling for PVC Pipe Application is a high-precision solution designed to produce durable and high-quality PVC pipes for various industrial applications. Manufactured from premium P20 steel, these extrusion dies ensure optimal performance and long-lasting durability, even under demanding production conditions. Using advanced CNC machining, Mirror EDM, and slow-speed wire-cutting technologies, we achieve the precise tolerances and smooth surfaces required for efficient extrusion processes. As a trusted OEM manufacturer, we provide end-to-end services, from design and prototyping to mass production and delivery, ensuring that our extrusion tooling meets the most rigorous standards for accuracy and functionality.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Product Material | P20 Steel |

| Runner System | Hot/Cold Runner |

| Mould Design Software | UG, PROE, SOLIDWORKS, CAD |

| Sample | Available upon request |

| Certification | ISO 9001, IATF 16949 |

| Packaging | Custom |

| MOQ | According to your requirement |

| Lead Time | 25-30 days |

| Surface Treatment Options | Nickel Plating, Chromium Plating, Polishing |

Surface Treatment Options:

- Nickel Plating: Enhances corrosion resistance and extends tool life under extreme working conditions.

- Chromium Plating: Provides improved hardness and resistance to wear, making the die suitable for high-precision extrusion processes.

- Polishing: Reduces friction and ensures a smooth surface finish, promoting better quality for the extruded PVC pipe.

Quality Assurance:

We adhere to stringent quality control protocols throughout the production process for our P20 Extrusion Die Molding Tooling. Our factory is ISO 9001 and IATF 16949 certified, ensuring that all products meet the highest industry standards. We perform rigorous inspections using advanced testing equipment such as Coordinate Measuring Machines (CMM), hardness testers, and surface roughness analyzers to ensure that each extrusion die meets precise dimensions and material integrity. Additionally, we conduct in-depth performance testing to validate the dies’ functionality during PVC pipe extrusion, ensuring reliable and efficient operation.

Factory Show:

Our advanced manufacturing facility is equipped with cutting-edge technologies, including CNC machining centers, Mirror EDM, and slow-speed wire-cutting systems. These tools guarantee high levels of precision in mold fabrication, providing the exact specifications needed for extrusion processes. To ensure consistent product quality, we use 15 rubber compression presses and 2 LSR injection molding machines, optimizing production efficiency while maintaining high tolerance levels. Our dedicated quality control team uses tools like 3D projectors, sealing testers, and elasticity gauges to monitor and maintain high manufacturing standards throughout each production stage. With ISO 9001 and IATF 16949 certifications, we guarantee that all extrusion dies are made with the highest attention to detail and craftsmanship.