Overview:

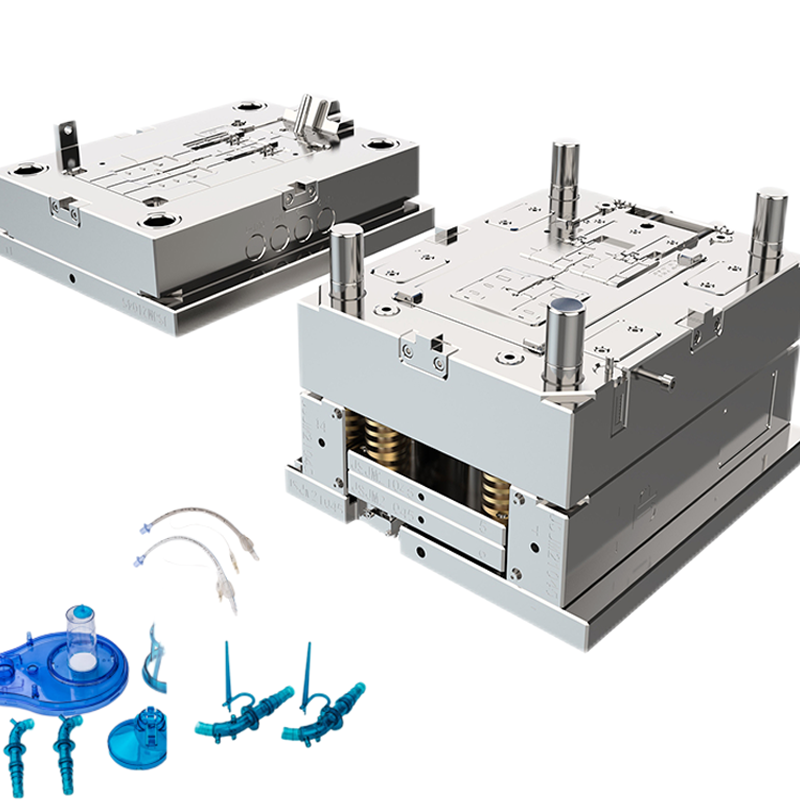

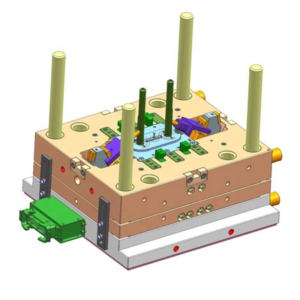

The Customized High Quality Medical Grade Steel Mold Tooling for Emergency Tracheal Tube Accessories is a precision-engineered solution designed for the production of critical components in the medical industry. Specifically crafted for manufacturing emergency tracheal tube accessories, this mold is made from high-quality medical-grade steel, ensuring durability, corrosion resistance, and long-lasting performance. Utilizing advanced technologies like EDM (Electrical Discharge Machining) and CNC machining, we guarantee exceptional precision and high-quality results. Our molds are designed to comply with ISO 13485 standards, ensuring the safety, reliability, and functionality required in medical applications. As an experienced manufacturer, we offer a one-stop solution, providing everything from custom mold design and prototyping to full-scale production, meeting the rigorous requirements of the healthcare sector.

Key Specifications:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Product Material | Medical-grade steel |

| Runner System | Hot/Cold Runner |

| Mold Design Software | UG, PROE, SOLIDWORKS, CAD, etc. |

| Sample Availability | Available upon request |

| Certification | ISO 13485, ISO 9001, IATF 16949 |

| Lead Time | 25-30 days |

| Surface Treatment Options | Nickel Plating, Hard Anodizing, Chromium Plating, Polishing |

| Packaging | Custom |

| MOQ | According to requirement |

| Temperature Range | -40°C to 250°C |

| Hardness | 40-80 HRC (depending on the mold design) |

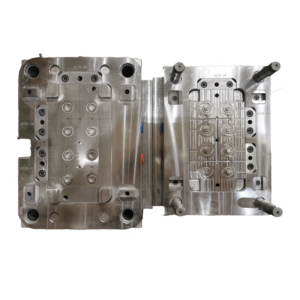

| Mold Type | Single cavity, multi-cavity (customizable) |

| Sample Lead Time | 5-7 business days |

Surface Treatment Options:

- Nickel Plating: Enhances mold durability by offering corrosion resistance and protecting against wear, especially in demanding environments. This extends the life cycle of the mold, providing long-term reliability in production.

- Hard Anodizing: This process significantly increases surface hardness and improves wear resistance, ensuring that the mold maintains its precision and performance through multiple production cycles.

- Chromium Plating: Provides superior protection against wear and corrosion, maintaining mold integrity even under extended use in high-demand applications.

- Polishing: The mold’s surface is refined through polishing, reducing friction and improving the quality of the molded products. This is particularly important for ensuring smooth operation and the flawless quality of medical components.

Benefits of Our Molds:

- Medical-Grade Steel: Crafted from premium medical-grade steel, our molds offer enhanced durability and corrosion resistance, meeting the stringent requirements of medical device manufacturing.

- Precision & Accuracy: Utilizing CNC machining and EDM, we ensure that each mold meets precise dimensions and tolerances, essential for manufacturing emergency tracheal tube accessories with high accuracy and quality.

- Customization: We offer fully customizable mold designs, tailored to meet the unique needs of your emergency tracheal tube accessory production. Whether it’s the mold size, runner system, or specific features, our molds are designed to optimize your production process.

- Quality Assurance: Adhering to ISO 13485 and ISO 9001 quality management systems, our molds undergo rigorous inspection using advanced tools such as coordinate measuring machines (CMM), hardness testers, and surface roughness analyzers to ensure reliable performance and safety compliance in the medical field.

Quality Assurance:

We follow stringent quality assurance protocols to guarantee that each Customized High Quality Medical Grade Steel Mold Tooling meets industry standards for medical devices. Our molds undergo comprehensive testing, including first-article evaluations, in-process audits, and final product inspections. Using tools like coordinate measuring machines (CMM), hardness testers, and surface roughness analyzers, we verify dimensional accuracy, material integrity, and sealing performance to ensure the molds are capable of producing high-precision medical components.

All of our molds are manufactured in compliance with ISO 13485 certification, which ensures the safety and reliability required for medical-grade applications. Our automated inspection systems help to maintain consistent product quality throughout the production process, ensuring that every mold performs to the highest standards.

Why Choose Us?

- Industry Expertise: Over two decades of experience in precision tooling for the medical industry, specializing in custom solutions for demanding medical applications.

- Certified Quality: Our ISO 13485, ISO 9001, and IATF 16949 certifications ensure that we adhere to the highest standards of medical device manufacturing.

- Customization & Flexibility: We offer customized solutions that meet the specific needs of your production, from design to large-scale manufacturing.

- Efficient Manufacturing: Equipped with the latest technologies and advanced automation, we guarantee quick turnaround times, cost-effective production, and consistent high-quality results.

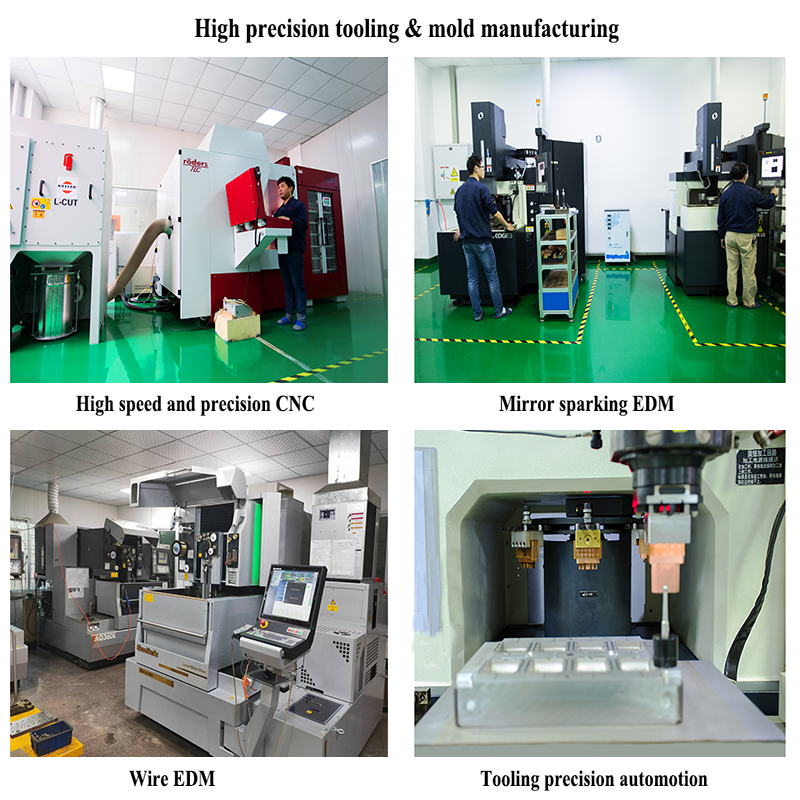

Factory Capabilities:

Our state-of-the-art manufacturing facility integrates advanced technologies such as CNC machining, Mirror EDM, conventional EDM, and Slow-Speed Wire Cutting (WC) for achieving unmatched precision in mold fabrication. Additionally, we use rubber compression molding presses and LSR injection molding units to handle a variety of medical-grade materials and achieve the desired product quality.

With ISO 9001 and IATF 16949 certifications, our factory maintains strict quality control processes at every stage of production. Our automated vision systems, along with advanced inspection tools like 3D projectors, sealing testers, durometers, and elasticity gauges, ensure high-precision production of molds and the final medical components.