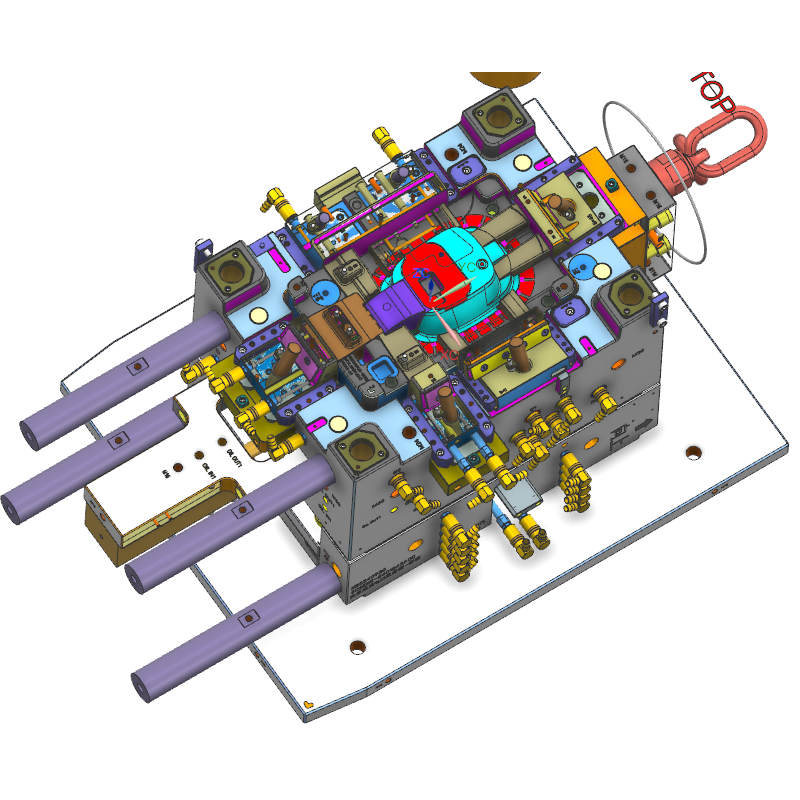

Overview:

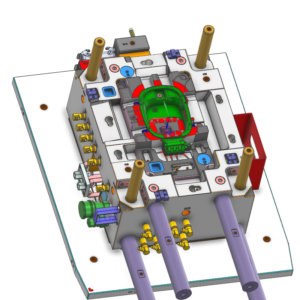

Our Custom SKD61/S136/H13 Tooling Molds for Electronics & Home Appliances are engineered for high-volume precision injection molding of intricate plastic components. Utilizing premium mold steels like SKD61 for heat resistance, S136 for superior polishability, and H13 for toughness, these molds are fabricated with advanced CNC machining, Mirror EDM, and precision grinding. They are designed to deliver exceptional dimensional stability, flawless surface finishes, and extended service life, meeting the rigorous demands of producing high-quality consumer electronics and appliance housings, internals, and accessories.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Core Mold Materials | SKD61, S136, H13, NAK80, P20, 420 Stainless Steel, etc. |

| Runner System | Hot Runner (Precision needle-valve) / Cold Runner |

| Mold Design Software | UG NX, Creo, SolidWorks, AutoCAD |

| Sample | Mold Trial Samples Provided |

| Certification | ISO9001, IATF16949 |

| Packaging | Wooden Case, Custom |

| MOQ | 1 Set |

| Lead Time | 30-45 Days (Depending on Complexity) |

Surface Treatment & Enhancement Options:

-

Nitriding: Increases surface hardness and wear resistance significantly, extending mold life for abrasive plastics or high-cavitation areas without dimensional change.

-

Hard Chrome Plating: Provides an extremely hard, low-friction surface that enhances release properties, resists corrosion from certain plastics, and simplifies maintenance.

-

Mirror Polishing & Texture: Achieves Class-A optical surfaces (SPI A1) for high-gloss parts or applies precise chemical/ laser textures (VDI, Mold-Tech) for matte or patterned finishes.

-

Titanium Nitride (TiN) Coating (PVD): A super-hard ceramic coating that drastically reduces wear, adhesion, and corrosion, ideal for molds processing glass-filled or corrosive materials.

Quality Assurance:

Our quality assurance for precision appliance and electronics molds is an integrated system spanning design, machining, and trial phases. Adhering to ISO 9001 and IATF 16949, we conduct rigorous DFM (Design for Manufacturability) analysis, followed by in-process inspections using CMM (Coordinate Measuring Machines) to verify core/cavity geometry against 3D models. Post-fabrication, molds undergo hardness testing to validate heat treatment and detailed inspection with profilometers for surface finish. The final validation is a formal mold trial, where we produce sample parts, measure critical dimensions, and perform fit/function checks to guarantee the mold meets all performance specifications before shipment.

Why Choose Us?

-

Material Science Expertise: We expertly select and process premium mold steels (SKD61, S136, H13) based on your specific application—prioritizing heat resistance, polishability, or toughness to optimize mold performance and longevity.

-

Precision Micro-Machining Capability: Our facility is equipped with high-precision CNC, Mirror EDM, and slow wire-cutting machines capable of producing intricate features, tight tolerances (±0.005mm), and optical-quality surfaces required for electronic components.

-

Holistic, Integrated Manufacturing: We manage the entire process from design and steel sourcing to machining, heat treatment, finishing, and trial, ensuring seamless quality control, communication, and accountability.

-

Proven Success in High-Volume Industries: Our molds are built to withstand long-term, high-cycle production runs typical in the home appliance and consumer electronics sectors, delivering consistent part quality and minimizing downtime.

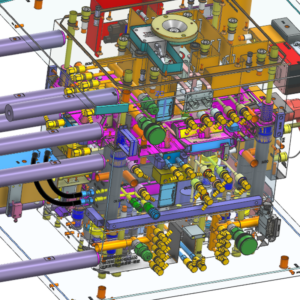

Factory Show:

Our mold manufacturing hub is equipped with state-of-the-art machinery, including multi-axis CNC machining centers, high-precision Mirror and CNC EDM machines, and slow wire-cut EDM for flawless tool steel processing. We operate dedicated heat treatment lines with precise atmosphere control for critical steels like H13 and SKD61. Quality verification is performed in our metrology lab, which houses large-travel CMMs, digital optical comparators, and surface roughness testers. Certified to ISO 9001 and IATF 16949, our process is managed by experienced tooling engineers who ensure every mold for electronics and appliances is built to the highest standards of precision, durability, and reliability.