Overview:

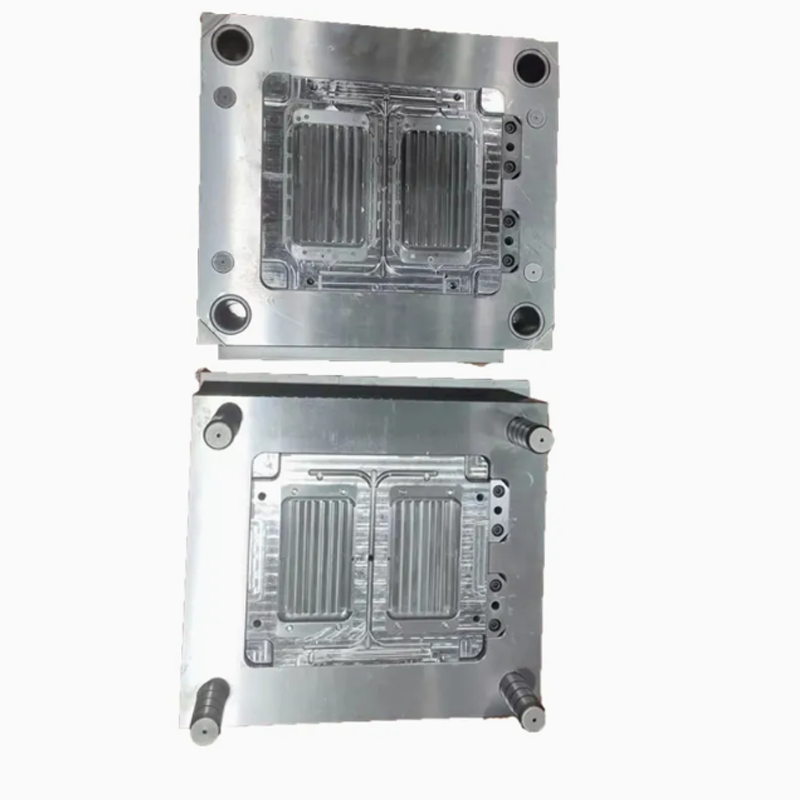

Custom Plastic Injection Mould Medical-Grade LSR Mold Tooling for Respiratory Mask Seals is precision-engineered tooling designed for manufacturing high-performance silicone seals used in respiratory therapy devices. The process involves high-precision CNC machining, EDM (electrical discharge machining), and rigorous surface finishing to ensure micron-level accuracy and airtight sealing properties. Molds are crafted from premium-grade tool steels (e.g., hardened H13 or stainless steel) paired with medical-grade liquid silicone rubber (LSR), which meets ISO 10993 biocompatibility standards for prolonged skin contact. Our factory specializes in custom design-to-production solutions, offering one-stop service from prototyping to mass production, including mold validation, material selection, and post-processing—ensuring fast turnaround, compliance, and seamless scalability for critical medical applications.

Features:

| Specification | Details |

| Raw Materials | ABS, PP, PC, PA66+30GF, PVC, POM, TPE, TPV, ASA, etc. |

| Die Steel | P20, P20HH, H13, 420, 2344, 2311 |

| Runner | Hot Runner / Cold Runner |

| Trademark | Customized |

| Design Software | AutoCAD, UG, Pro/E |

| Certification | TS16949, ISO 9001, ISO 13485 |

| Transport Package | Wooden Box or Carton Box |

| Production Capacity | 500 sets/year molds |

| Color | Customizable |

| MOQ | Small orders accepted |

| Place of Origin | Xiamen, China |

Surface Treatment Options:

- Polishing: Smooths and refines surfaces using progressively finer abrasives to reduce scratches and improve tactile feel.

- Mirror Polishing: Delivers a highly reflective, glass-like finish by employing ultra-fine abrasives and buffing compounds.

- Sand Blasting: Propels abrasive media at high velocity to uniformly clean, texture, or prep surfaces for subsequent coatings.

- Painting: Applies durable liquid or powder coatings to enhance corrosion resistance, aesthetics, and wear protection.

Benefits of Our Mold:

-

Ultra-Precision Machining (CNC/EDM):

Advanced CNC milling and electrical discharge machining (EDM) ensure micron-level cavity accuracy, critical for seamless, leak-free seals that meet strict medical airtightness requirements.

-

Validated Biocompatibility & Compliance:

Tooling is rigorously tested under FDA/ISO 13485 protocols, with material traceability for medical-grade LSR (ISO 10993 certified), guaranteeing safety for prolonged skin contact in respiratory therapies.

-

Optimized Cycle Efficiency with Cold Runner Systems:

Custom-designed cold runner molds minimize material waste, reduce curing time, and enable high-volume production scalability—ideal for fast-turnaround medical device orders.

-

Durable Tool Steel Construction (H13/Stainless Steel):

High-hardness tool steels resist wear and corrosion, extending mold lifespan even under frequent sterilization (e.g., autoclaving), lowering long-term per-part costs for OEMs.

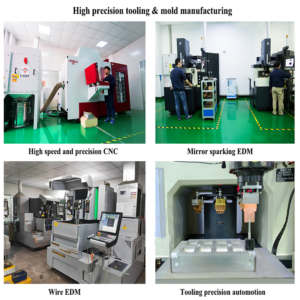

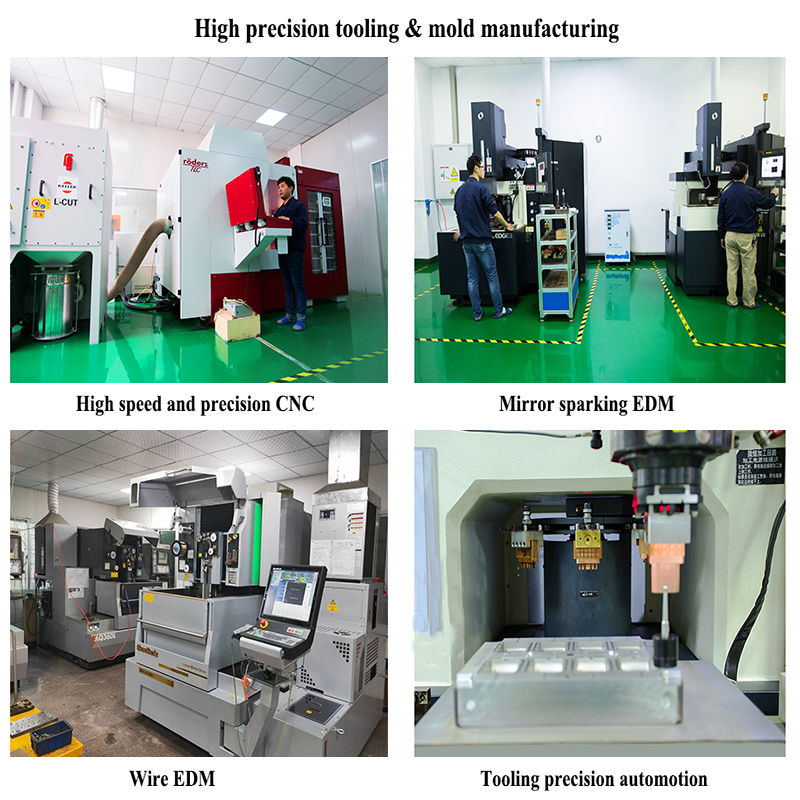

Factory Show:

Our facility combines advanced CNC machining centers, mirror and conventional EDM, and high-precision wire-cutting to achieve unparalleled mold accuracy and repeatability. With 15 rubber compression presses and 2 state-of-the-art LSR injection machines, we seamlessly manage both high-volume production and bespoke tooling projects. Rigorous QA—driven by seasoned specialists and ISO 9001/IATF 16949 certification—is enforced via 3D projectors, seal-integrity testers, durometers, and elasticity gauges. Integrated automation (AutoDryers, high-speed doming, precision die-cutting) further optimizes throughput and consistency, delivering performance-critical components that meet the strictest industry requirements.