Overview

This bespoke P20 steel tooling is engineered to produce high-precision silicone gaskets for shower nozzles via LSR injection and silicone compression molding. The toolset combines a P20 mold base with hardened tool-steel core/cavity inserts to deliver tight tolerances, long service life, and excellent surface finish for seals used in wet, high-use bathroom environments. Designed and manufactured in-house, the tooling supports hot/cold runner arrangements, integrated temperature control, and is optimized for automated LSR molding lines and compression presses. Full OEM, one-stop service is provided — from DFM and prototyping through mold tryout, validation, and production transfer.

![]()

![]()

Key Specifications

| Attribute | Specification |

|---|---|

| Place of Origin | Xiamen, China |

| Mold Base | P20 pre-hardened steel |

| Core / Cavity Inserts | Hardened tool steels (e.g., H13 / 718) |

| Suitable Processes | LSR injection molding & silicone compression molding |

| Runner System | Hot runner (LSR compatible) or cold/valve gate options |

| Cavity Count | Custom (single to multi-cavity layouts available) |

| Mold Life (est.) | 500,000 — 1,000,000 shots (material/process dependent) |

| Dimensional Tolerance | ±0.02 mm (typical) |

| Surface Finish | Ra ≤ 0.2 µm (polished or textured per spec) |

| Temperature Control | Integrated oil/water channels, cartridge heaters for LSR |

| Draft/Parting | Optimized demold angles & ejector design for silicone parts |

| Mould Design Software | UG, Creo/PROE, SolidWorks, AutoCAD |

| Sample / Prototype | Prototype cavities & T0 samples available |

| Certifications | ISO 9001, IATF 16949 (manufacturing facility) |

| Lead Time | Tooling: 25–35 days (depending on complexity) |

Benefits of Our Tooling:

1. Exceptional Dimensional Accuracy

– Advanced CNC machining, Mirror EDM, and precision wire-cutting techniques ensure micron-level tolerances (±0.02 mm), delivering perfectly fitting gaskets and minimizing post-production adjustments.

2. Enhanced Mold Durability & Longevity

– Hardened tool-steel cores and P20 steel bases, combined with optional surface treatments such as electroless nickel plating or hard chrome, provide superior wear and corrosion resistance, enabling up to 1,000,000 molding cycles with consistent performance.

3. Optimized LSR Flow & Ejection

– Integrated hot/cold runner systems, temperature-controlled channels, and precision-engineered draft angles reduce cycle times, improve material flow, and ensure reliable ejection of silicone parts without deformation or flash.

4. Scalable OEM Production Capability

– Designed for both LSR injection and silicone compression molding, the tooling supports single- to multi-cavity layouts, enabling high-volume production while maintaining tight tolerances, consistent surface finish, and repeatable quality for all shower nozzle gaskets.

Surface Treatment Options

- Electroless Nickel Plating — Uniform corrosion protection and improved cavity hardness for long life.

- Hard Chrome Plating — Wear-resistant, low-friction finish to aid part release and reduce maintenance.

- Polishing (Mirror / Matte) — Achieves the required Ra for sealing faces and aesthetic surfaces.

- Texturing — Controlled texture application for grip or visual requirements while preserving sealing performance.

Quality Assurance & Test Equipment

Tooling and first-article gaskets are validated under our ISO 9001 / IATF 16949 quality system. Final inspection includes:

- Coordinate Measuring Machine (CMM) verification

- 3D optical projection for geometric checks

- Surface roughness measurement

- Hardness testing of inserts

Mold trials include:

- Process stability runs on LSR injection presses and compression molding presses

- Leak/seal testing of molded gaskets

- Thermal cycling to confirm dimensional stability across bathroom environment temperature ranges

Full documentation (FAI, SPC, maintenance plan) is provided with each tool.

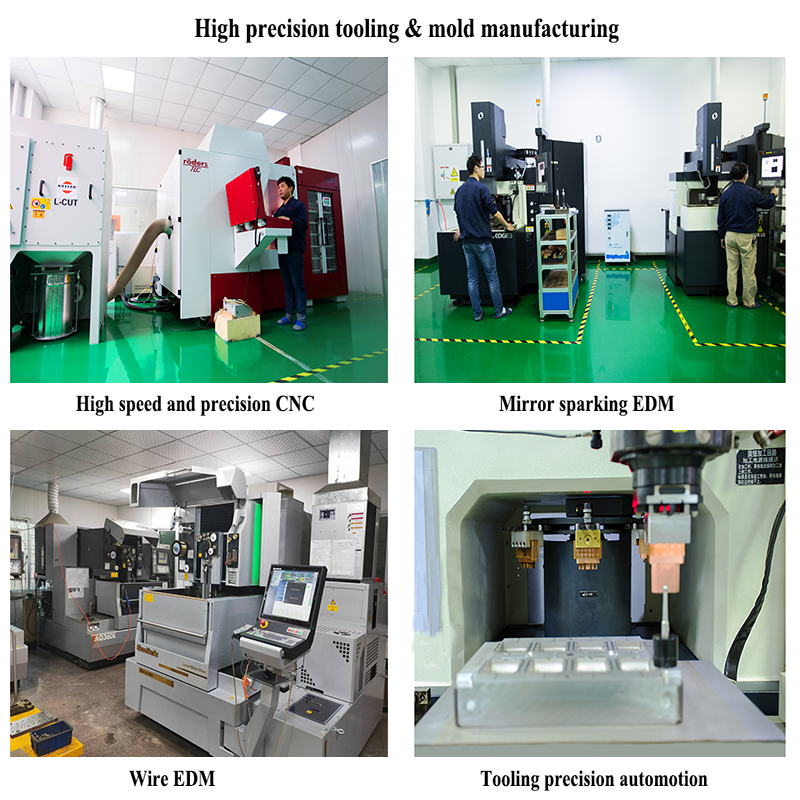

Factory Capabilities

Our in-house tool shop features high-precision CNC centers, Mirror and conventional EDM machines, slow-speed wire-cutters, surface grinders, and polish stations, supporting comprehensive mold fabrication and finishing. We operate dedicated LSR injection molding and silicone compression lines for mold tryouts and production validation, complemented by specialized tooling assembly and maintenance teams to ensure long-term operational reliability. Offering full end-to-end OEM services—including design, prototyping, mold manufacturing, trial runs, and production handover—we can tailor tooling designs and validation plans to accommodate custom cavity counts, specific surface finishes, and medical or food-grade silicone compatibility. Prospective clients are invited to contact our tooling engineers to initiate DFM and obtain a detailed quote and production timeline.