Custom Mold Display

Here are molds spanning various industries, each meticulously designed and manufactured with rigorous processes. Additionally, we offer comprehensive customization services, ensuring that no matter your industry, we can tailor a mold to meet your specific needs.

Overview This Custom High Standard Overmolding Mold Tooling is engineered for producing integrated rice cooker control panels with soft-touch keypads. It precisely bonds rigid substrates (PC/ABS) to TPE/silicone, ensuring waterproof seals and a premium feel. We deliver IATF 16949 certified, high-volume solutions from design to production. Characteristics: Attribute Details Place of Origin Xiamen, China Brand […]

Overview Our customized injection mold tooling for plastic baby bath tubs is engineered for safety, precision, and high-volume production. Utilizing food-grade materials like PP and TPE, our molds guarantee smooth, seamless surfaces free of sharp edges. We integrate efficient cooling and automated ejection for optimal cycle times, delivering durable, child-safe products through OEM and fully […]

Overview Our custom tooling molds precision compression molds for durable silicone cylinder bellows. Engineered from premium steels with CNC and EDM machining, they ensure exacting concentricity and wall thickness. We provide complete OEM solutions, from design to tooling, for reliable production of flexible, leak-proof protective bellows for automotive, industrial, and medical applications. Basic Information Attribute […]

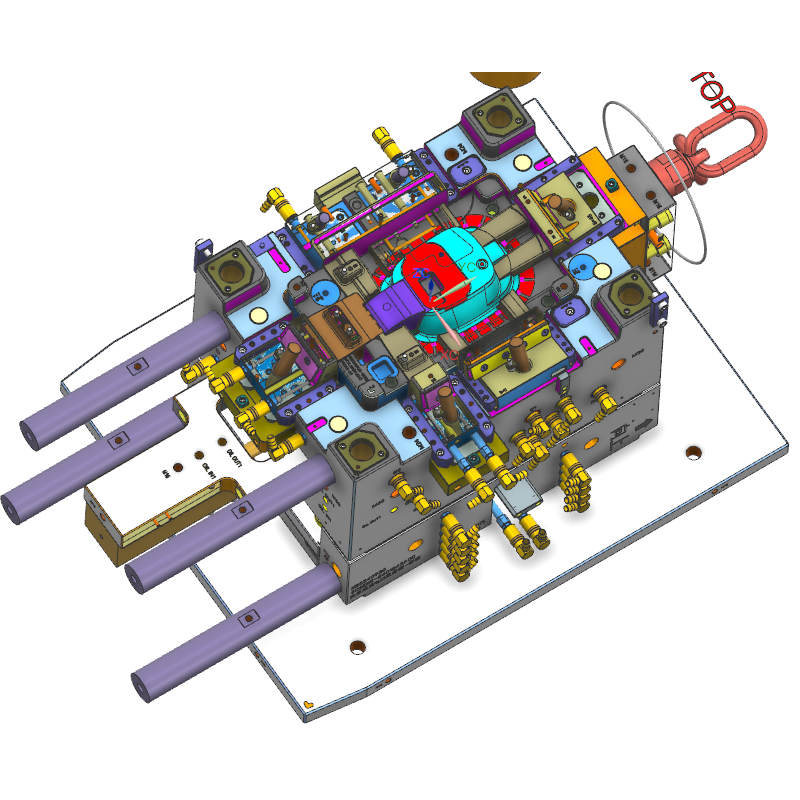

Overview: Our Custom SKD61/S136/H13 Tooling Molds for Electronics & Home Appliances are engineered for high-volume precision injection molding of intricate plastic components. Utilizing premium mold steels like SKD61 for heat resistance, S136 for superior polishability, and H13 for toughness, these molds are fabricated with advanced CNC machining, Mirror EDM, and precision grinding. They are designed […]

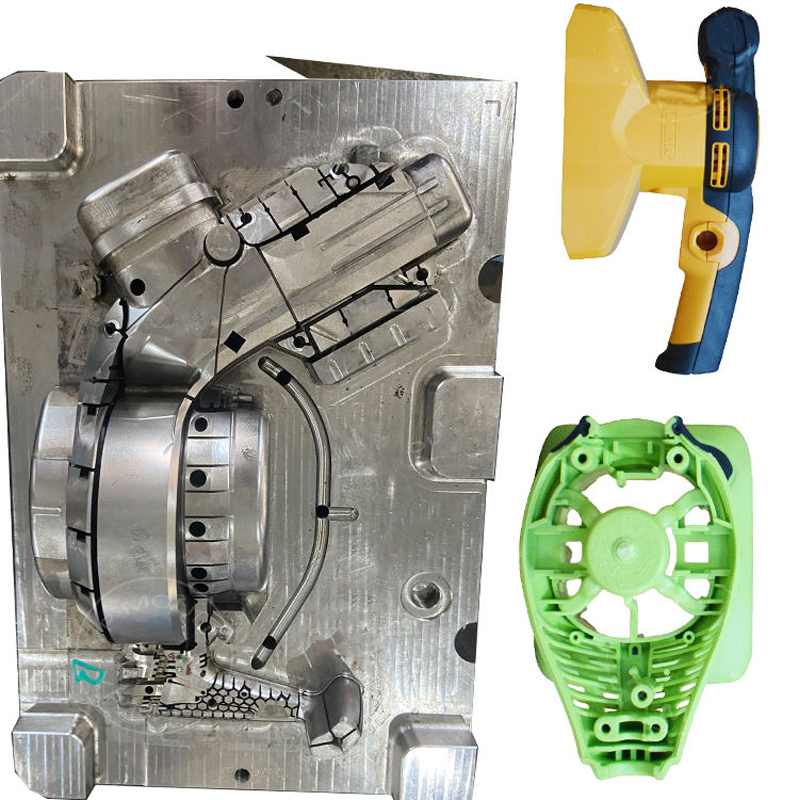

Overview Our Custom Plastic Injection Tooling for Overmolding Electric Tools is engineered to produce durable, ergonomic components like handles, grips, and housings. Utilizing advanced CNC and EDM machining, our molds enable precise hard-soft material bonding (e.g., PC-ABS + TPE) in a single cycle, enhancing tool durability, user comfort, and assembly efficiency. Basic Information Specification Details […]

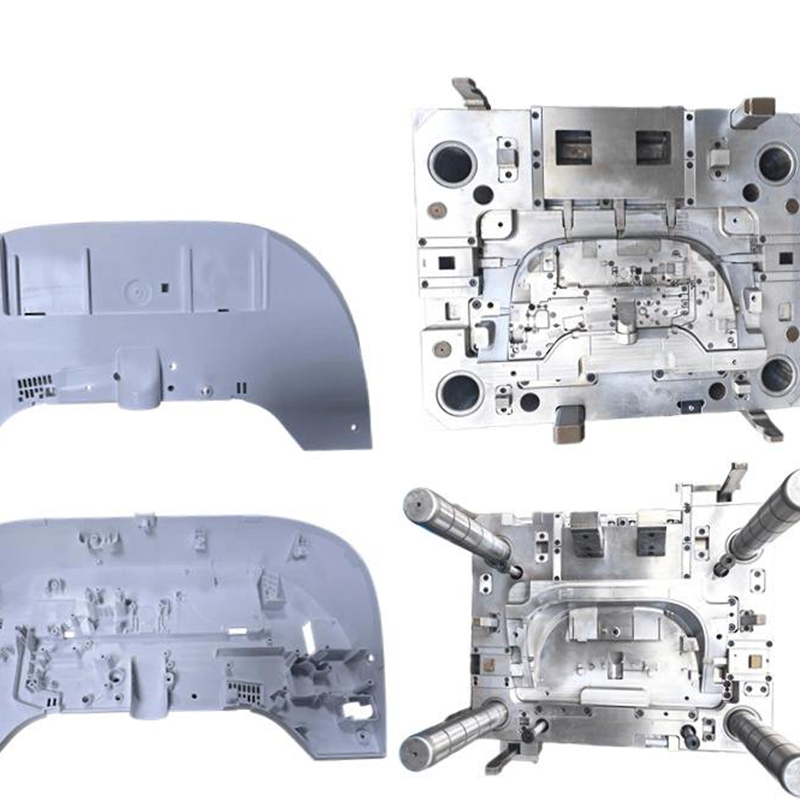

Overview The Custom Precision Plastic Injection Mold Tooling for Bathroom Covers (Sanitary Ware & Household) is engineered to produce high-quality, cosmetically perfect plastic covers and trim components for toilets, bidets, faucet escutcheons, shower trims, vanity hardware, drain covers, and related sanitary fixtures. Our tooling supports thin-wall molding, tight cosmetic tolerances, multi-cavity layouts, insert and overmold […]

Overview Our Customized High-Precision Injection Mold Tooling for Silicone & Plastic Festival Promotion Gift Parts is engineered to deliver eye-catching, durable, and cost-effective promotional items for seasonal retail and brand campaigns. Designed for parts such as mascot toys, glow-in-the-dark gifts, soft-touch keychains, novelty lights, and multi-material promo items, these tools support single- and multi-shot molding, […]

Overview Our Customized High-Precision Injection Mold Tooling for Silicone & Plastic Festival Promotion Gift Parts is engineered to produce eye-catching, durable promotional items — from soft-touch silicone keychains and novelty lights to glossy plastic toys, badge holders, and multi-material gifts. Designed for single-shot plastics, LSR/LSR-to-plastic overmolding and 2-K runs, these molds deliver consistent color fidelity, […]

Overview Our Custom High-Precision Injection Molding Tooling for Baby Toilet Seats is engineered for safe, durable, and cosmetically perfect baby-care components. Built for single- and multi-shot molding of rigid shells and soft TPE cushions (2K / overmolding), these molds deliver tight dimensional control, glossy hygienic surfaces, and robust cycle life for high-volume production. Each tool […]

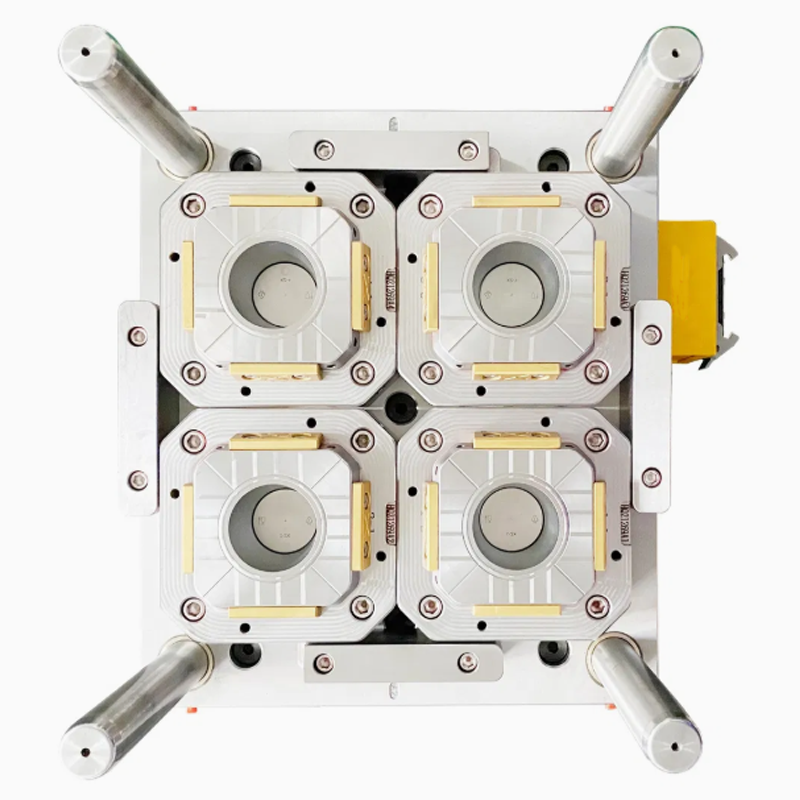

Overview Our Personalized Plastic Injection Molding Mold Tooling for Electronics Parts & Household Products — China delivers precision, repeatability, and fast time-to-market for consumer electronics, small appliances, connectors, enclosures, switches, and other household components. Custom-designed per part geometry and production volume, these molds combine optimized hot-runner or cold-runner systems, balanced cooling, and precision cavity machining […]