At LSRmold, we know how critical tooling is to the success of any injection molding project. From part quality to production speed and operational costs, your tooling decisions set the foundation for everything that follows. Many companies underestimate how much tooling design, material selection, and build quality influence their final product’s performance and reliability. That’s why getting the tooling quote process right isn’t a formality — it’s a strategic, money-saving step.

In this blog, we’ll share five expert tips to help manufacturers, product developers, and procurement teams gather the right information and ask the right questions when securing injection molding tooling quotes. As a professional manufacturer and one-stop service supplier based in China, we’ve seen how thorough preparation upfront leads to smoother production, better tooling longevity, and superior end results.

Why Tooling Quotes Are More Critical Than Ever

Today’s manufacturing landscape has changed. Global supply chain disruptions, material price increases, and tariffs on imported molds, steel, and aluminum have driven tooling costs higher. Many OEMs are exploring reshoring, nearshoring, and hybrid supply models to control costs and reduce risk.

But no matter where your tooling is made, the quote you receive must accurately reflect the technical and financial realities of your project. At LSRmold, we help customers navigate this process with transparency and expertise, ensuring no critical details get overlooked.

5 Tips for Accurate, Reliable Tooling Quotes

1️⃣ Determine the Right Cavity Count for Your Needs

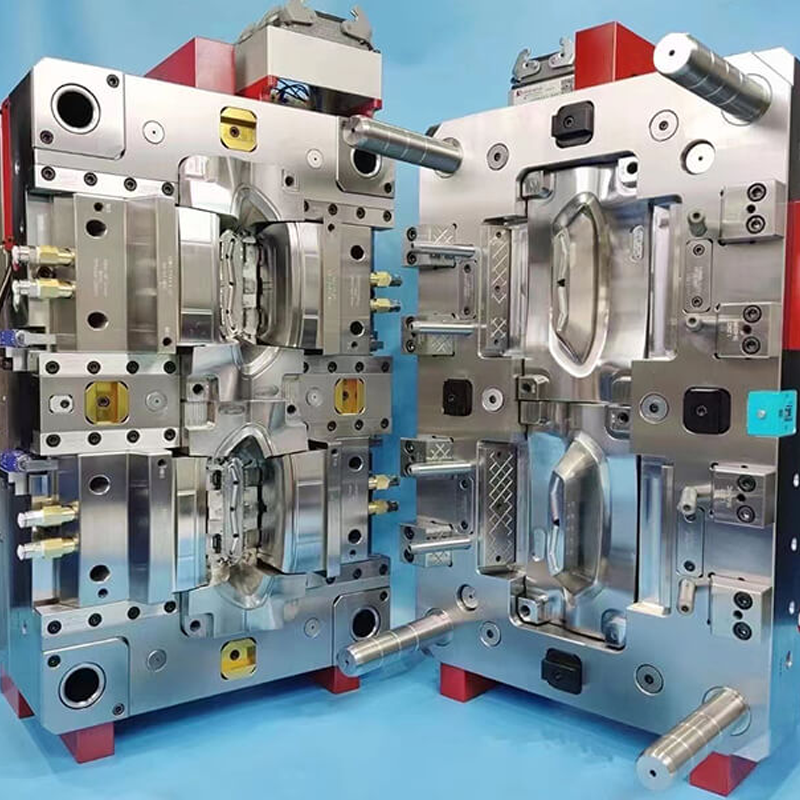

One of the first decisions to make is whether your tool should have a single or multiple cavities. Fewer cavities mean lower tooling costs and easier maintenance, but higher per-part prices. Multi-cavity molds speed up production but cost more upfront and may be more complex to maintain.

Never decide cavity count based on part price alone. A qualified injection molding supplier like LSRmold will work with you to evaluate your production volume forecasts, part tolerances, and long-term operational costs to recommend the most efficient solution.

2️⃣ Specify Tooling Material Clearly

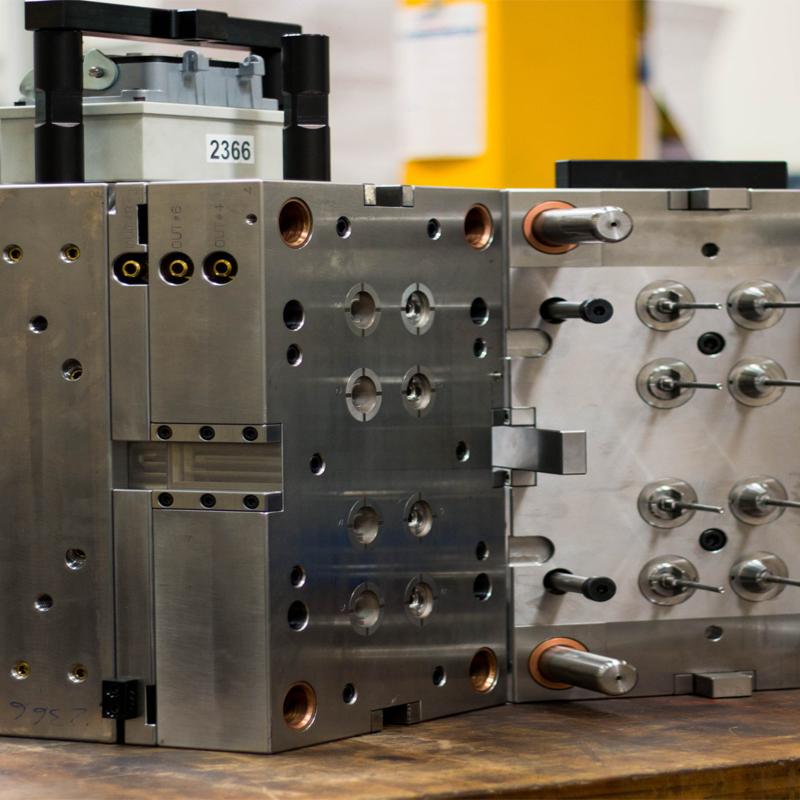

Tooling material selection isn’t one-size-fits-all. While P20, H13, or S136 steels are common, softer steels or aluminum molds may be appropriate for lower-volume runs or prototypes.

Factors to consider:

- What material is being molded?

- What’s the expected tool life?

- How critical are part tolerances?

- Will you need quick tooling adjustments?

We always advise clients to clarify their long-term needs upfront. This prevents misaligned expectations and makes sure your tooling quote reflects both initial and maintenance costs.

3️⃣ Understand Gate and Runner Systems Early

The gate and runner system in your mold controls how material flows into the cavities, impacting fill balance, cycle times, and part quality. It’s crucial to understand how your supplier plans to gate your tool and why.

If a quote lacks details about the gating system, ask for an explanation. A good one-stop service manufacturer like LSRmold should be able to offer a clear rationale based on part design, material behavior, and production goals. Adjustments here can prevent costly tooling changes later.

4️⃣ Communicate All Special Requirements

Never assume your supplier knows every aspect of your product or its production needs. Share every detail, no matter how minor it seems — from specific part ejection requirements to anticipated cosmetic finishes or material certifications.

Injection molding can place high stresses on tooling, so it’s also wise to clarify expectations around tool maintenance, spare inserts, and repair timelines. At LSRmold, we cover these items in every project review, ensuring your tooling will perform reliably over its lifespan.

5️⃣ Be Cautious with Seemingly Low-Cost Overseas Tools

Price should never be your only decision-making factor when sourcing injection molds. While overseas options might offer lower unit prices, hidden costs in shipping, repairs, and quality control can quickly add up.

At LSRmold, we provide clients with side-by-side cost-benefit analyses of domestic vs. overseas tooling options, including production lead times, maintenance support, and long-term ROI. This helps you make an informed decision that balances immediate savings with operational stability.

Why Work with LSRmold?

As a specialized manufacturing partner and one-stop service supplier for injection molding tooling, LSRmold offers:

- Over 15 years of tooling manufacturing experience

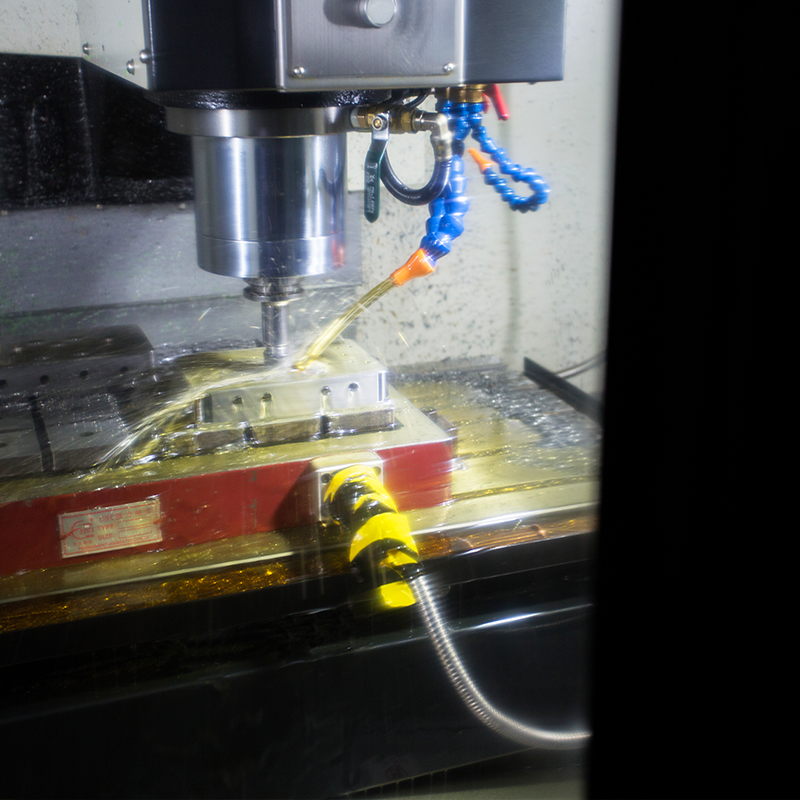

- In-house engineering for DFM, mold flow analysis, and tooling design

- ISO 9001 and IATF 16949 certified facilities

- Rapid prototyping and bridge tooling options

- Localized after-sales support in key international markets

Whether you need prototype tooling, high-cavitation production molds, or specialized tools for silicone, LSR, or medical-grade materials, we have the capability and capacity to deliver.

Final Thoughts: Let’s Optimize Your Next Project Together

Getting your injection molding tooling quote right saves time, money, and stress down the line. It’s about more than numbers — it’s about clear communication, smart decision-making, and partnering with a reliable manufacturer who can deliver high-quality tools on time.

At LSRmold, we’re ready to help you optimize your next tooling program. Contact our team for a fast, no-obligation quote and expert technical support. Let’s build something excellent together.Would you like us to evaluate your existing tooling specs or suggest improvements for a current project? Reach out to our one-stop service team at LSRmold today — we’re always here to help.