At LSRmold, we know that many newcomers, designers, and even purchasing managers often find plastic injection molding intimidating at first glance. Questions like “What exactly is a plastic injection mold?” or “Why is mold design so critical in mass production?” come up frequently during our client consultations. As a professional factory in China specializing in high precision mold manufacturing and OEM service, we’ve seen firsthand how the right mold makes the difference between a flawed product and a market-ready success. This guide is designed to help you understand the essentials of plastic injection molds, whether you are new to product design, sourcing molds from global suppliers, or looking for a reliable partner that offers one-stop service.

What Is a Plastic Injection Mold?

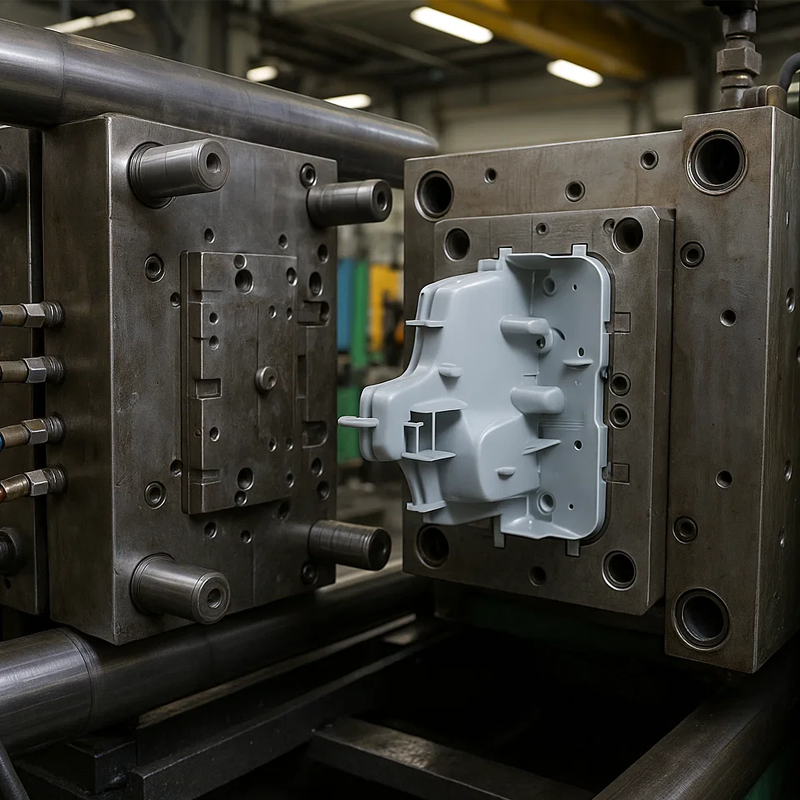

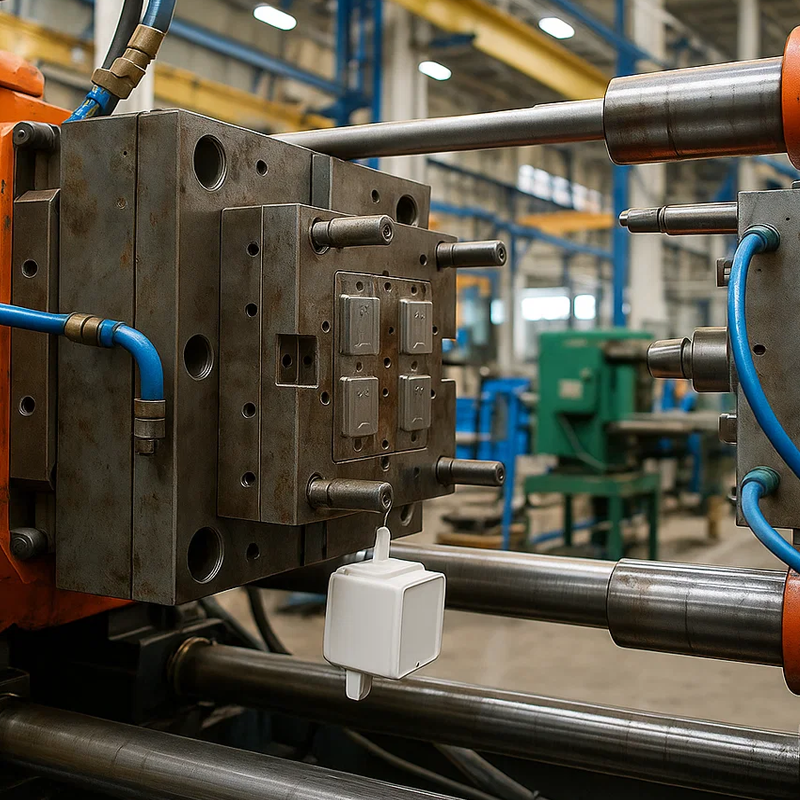

A plastic injection mold is a precisely engineered tool used to shape molten plastic into final parts. The process is simple in concept but highly technical in practice: plastic pellets are heated until they melt, then injected into a mold cavity under pressure. Once cooled, the plastic solidifies and is ejected as a finished product.

From medical devices and automotive components to consumer goods and packaging, plastic injection molds are at the heart of mass manufacturing. It’s no exaggeration to call molds the “mother of industry”, as almost every mass-produced product relies on them in some form.

Why Are Injection Molds So Important in Manufacturing?

The importance of molds extends far beyond shaping plastic. They impact:

- Efficiency: A well-designed mold reduces cycle times, increasing overall output.

- Quality: High precision molds ensure consistency across thousands—or even millions—of parts.

- Cost-effectiveness: By enabling automation and reducing material waste, molds lower long-term production costs.

- Innovation: Complex geometries and multi-material designs are only possible through advanced mold engineering.

At LSRmold, we use DFM (Design for Manufacturability) analysis before tooling begins, ensuring every mold is optimized for both product performance and cost efficiency.

Types of Plastic Injection Molds

Injection molds can be categorized in different ways depending on application, material, or production volume. Here are some key classifications:

By Product Material

- Plastic injection molds – the most common type, producing standard plastic parts.

- Metal injection molds – used in die-casting for aluminum, zinc, and magnesium parts.

- Silicone injection molds – ideal for flexible products such as medical tubing or kitchenware.

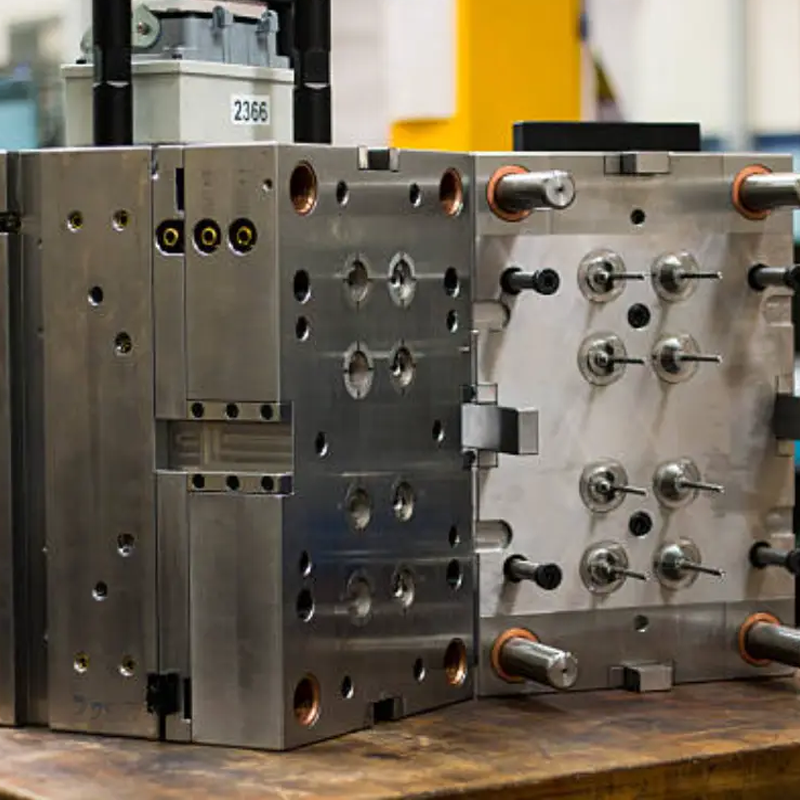

By Mold Material

- Aluminum molds – cost-effective, lightweight, ideal for prototyping and low-volume runs.

- Steel molds – highly durable, suitable for high-volume production, though more expensive.

- Beryllium copper molds – excellent for heat transfer, often used in high-precision inserts.

By Cavity Count

- Single-cavity molds – produce one part per cycle, perfect for specialized designs.

- Multi-cavity molds – deliver multiple identical parts per cycle, maximizing productivity.

- Family molds – create different parts in one cycle, ideal for assemblies.

By Special Features

- Insert molds – allow metal or other components to be embedded in plastic.

- Overmold / Two-shot molds – used for multi-material parts like soft-grip tools.

- Hot runner molds – keep plastic flowing to minimize waste and improve efficiency.

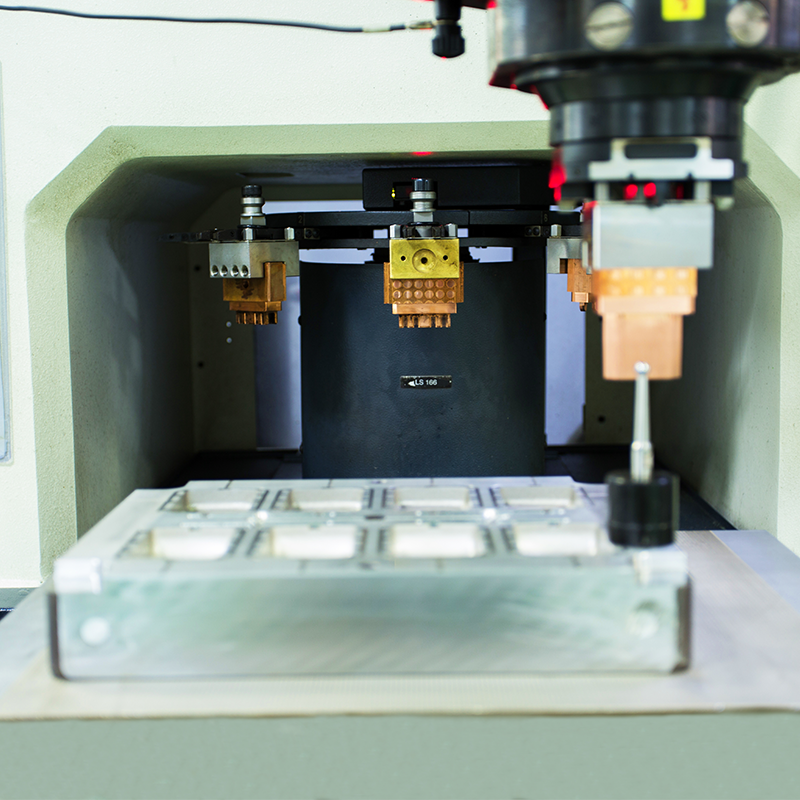

Anatomy of an Injection Mold

An injection mold is a complex system with several integrated components:

- Molding system – cores and cavities that form the part shape.

- Gating system – runners and gates that channel molten plastic into the mold.

- Temperature control system – cooling lines that regulate mold temperature.

- Ejection system – ejector pins and plates that release the part safely.

- Guiding and sliding systems – ensure precise alignment and enable complex geometries.

- Venting system – removes trapped air to avoid defects.

Each of these subsystems must be carefully designed and manufactured with high precision to ensure mold performance.

Workflow of Injection Mold Manufacturing

At LSRmold, our one-stop service covers the entire journey from concept to production mold. A typical workflow looks like this:

- Receive customer drawings and requirements.

- Conduct DFM review to ensure manufacturability.

- Finalize mold design and gain customer approval.

- Source mold steel and other materials.

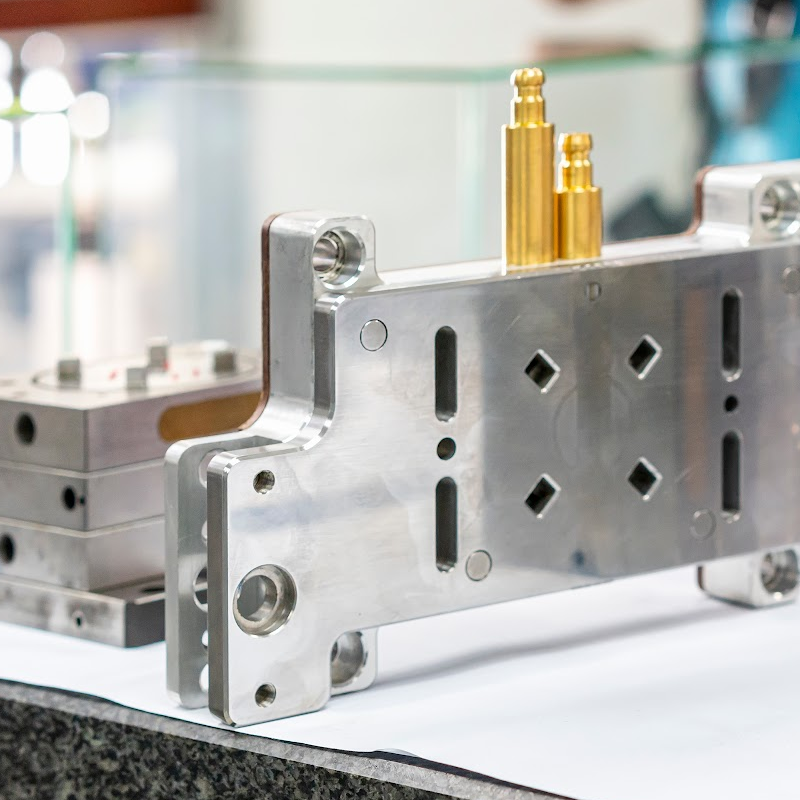

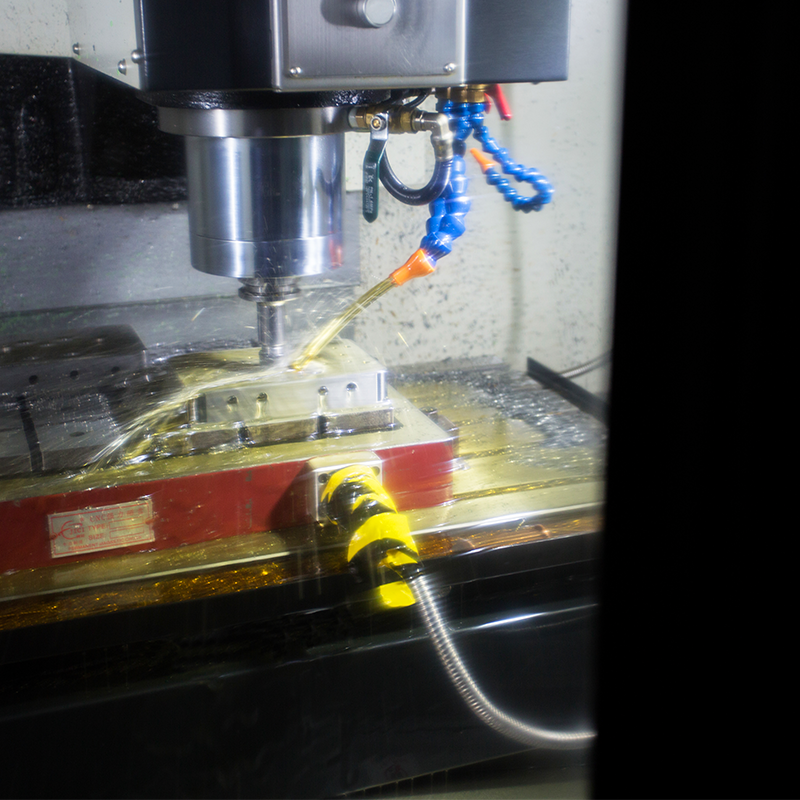

- Precision machining (CNC, EDM, wire cutting).

- Assembly and fitting.

- Mold trials and sample approval.

- Final adjustments and delivery.

This structured process guarantees both accuracy and efficiency, giving clients confidence that their molds are production-ready.

Materials Used in Injection Molds

The choice of mold material determines durability, cycle time, and part quality. Common materials include:

- Steel grades such as P20, 718, and H13 for long-life molds.

- Aluminum alloys for rapid tooling and prototype runs.

- Beryllium copper for inserts requiring excellent heat dissipation.

Our factory sources only high-grade materials from trusted suppliers, ensuring every mold meets international standards.

Mold Maintenance and Longevity

Injection molds are significant investments, so proper maintenance is crucial. At LSRmold, we advise our customers on preventive maintenance routines, including:

- Regular cleaning and lubrication.

- Protecting against rust and corrosion.

- Monitoring ejector pins and wear-prone parts.

- Performing periodic inspections to avoid costly breakdowns.

Well-maintained molds can run millions of cycles, dramatically lowering the cost per part.

Common Defects and How to Avoid Them

Even the best molds may encounter challenges. Common issues include:

- Flash – excess plastic at the parting line.

- Warping – uneven cooling causing distortion.

- Short shots – incomplete filling of the mold cavity.

- Sink marks – depressions due to cooling inconsistencies.

Through DFM review, high precision machining, and rigorous testing, our factory minimizes these risks, ensuring our customers receive molds that deliver consistent, defect-free production.

Mold Design: The Key to Success

The success of any mold project begins with its design. Good mold design considers:

- Part geometry and material properties.

- Cooling efficiency for cycle time optimization.

- Ease of ejection and maintenance.

- Compatibility with the customer’s injection molding machine.

Our experienced design team provides full OEM service, supporting customers with CAD design, simulation, and iterative improvements before cutting steel.

Why Partner with LSRmold?

As a leading factory in China, LSRmold doesn’t just manufacture molds—we provide a complete one-stop service. From early-stage consultation to DFM analysis, high precision machining, and OEM service, we help our customers bring products from concept to reality with confidence.

Unlike trading companies, we are true manufacturers, giving you direct control, faster communication, and competitive pricing without sacrificing quality. Our global clients trust us because we combine advanced technology, skilled craftsmanship, and strict quality control at every step.

Conclusion: Let’s Build Better Products Together

Plastic injection molds are the backbone of modern manufacturing. For newcomers, designers, and sourcing managers, understanding how molds are designed, built, and maintained is essential to ensuring product success. At LSRmold, we are proud to be more than just a supplier—we are your factory partner, offering high precision molds, OEM service, and one-stop solutions tailored to your needs.

Are you currently developing a new plastic product or looking for a reliable mold partner? Contact LSRmold today, and let’s create molds that drive your business forward.