Are you frustrated by intermittent defects, late rework cycles, or inconsistent part quality from your molding supplier? At LSRmold, we hear that every day — and we build systems to solve it. In this post I’ll walk you through how modern automated quality checks are engineered into real production lines, why they’re essential for high-precision […]

Technology & Process

From Welding to Overmolding — A Practical Guide to Plastic Joining Methods

Are you evaluating assembly options for a new plastic product and unsure which joining method will deliver the right balance of strength, cost, and manufacturability? At LSRmold, we work with OEMs and suppliers every day to design parts that assemble reliably at volume. In this guide, written from the factory floor perspective, we’ll walk you […]

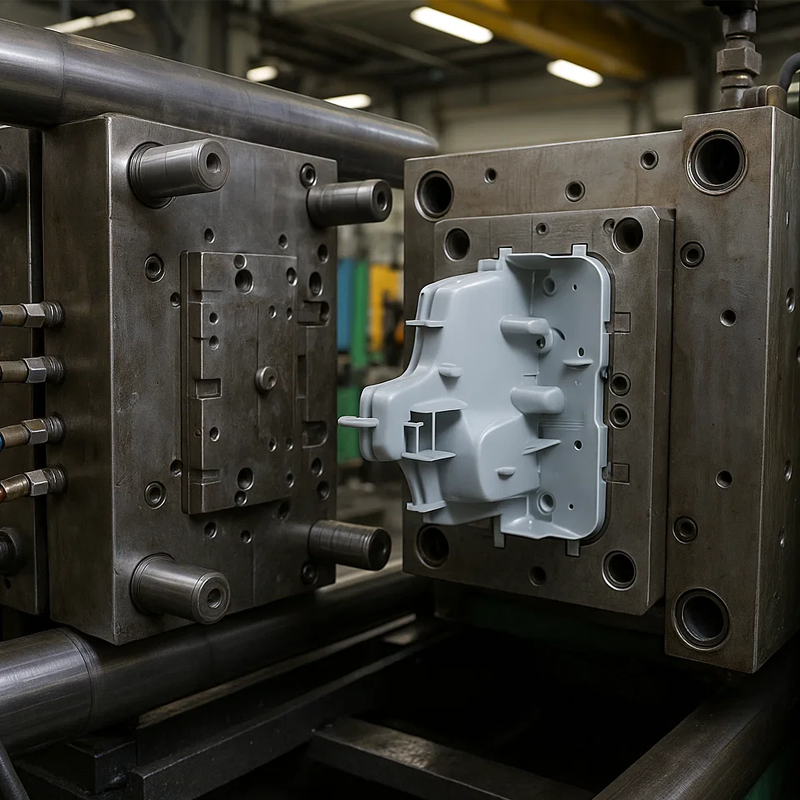

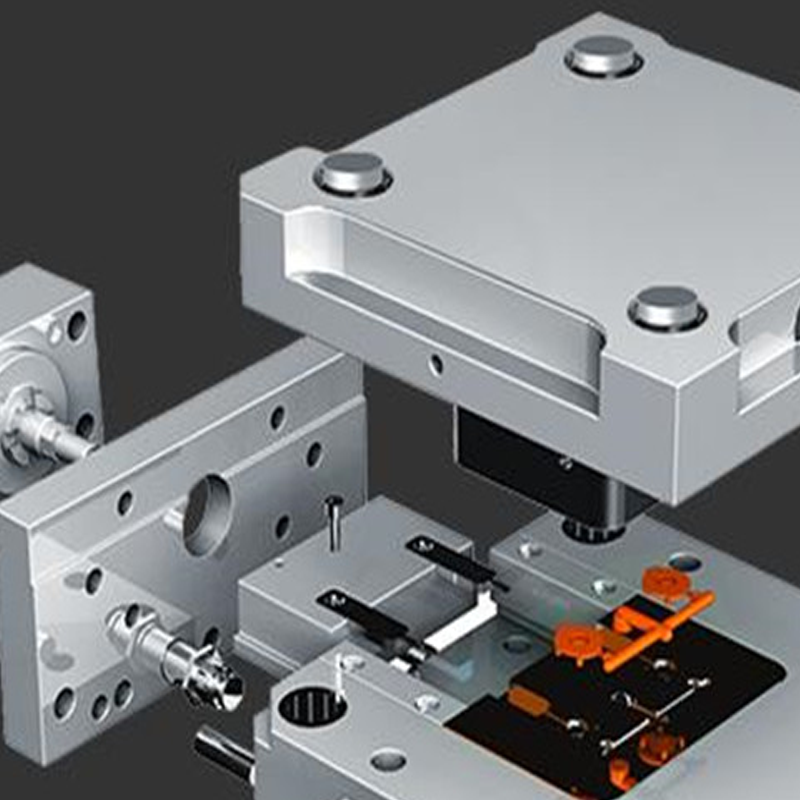

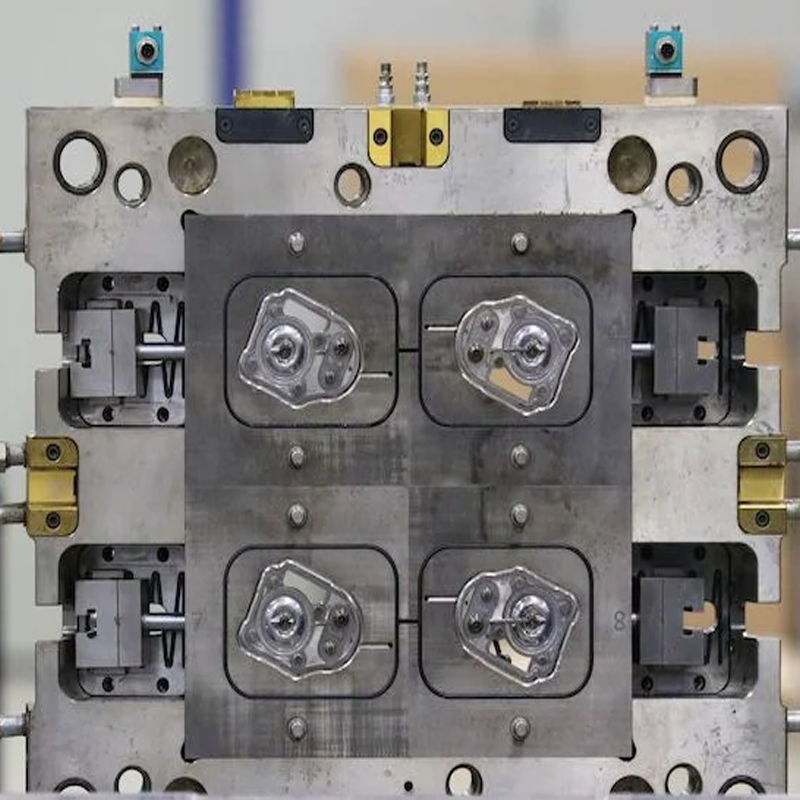

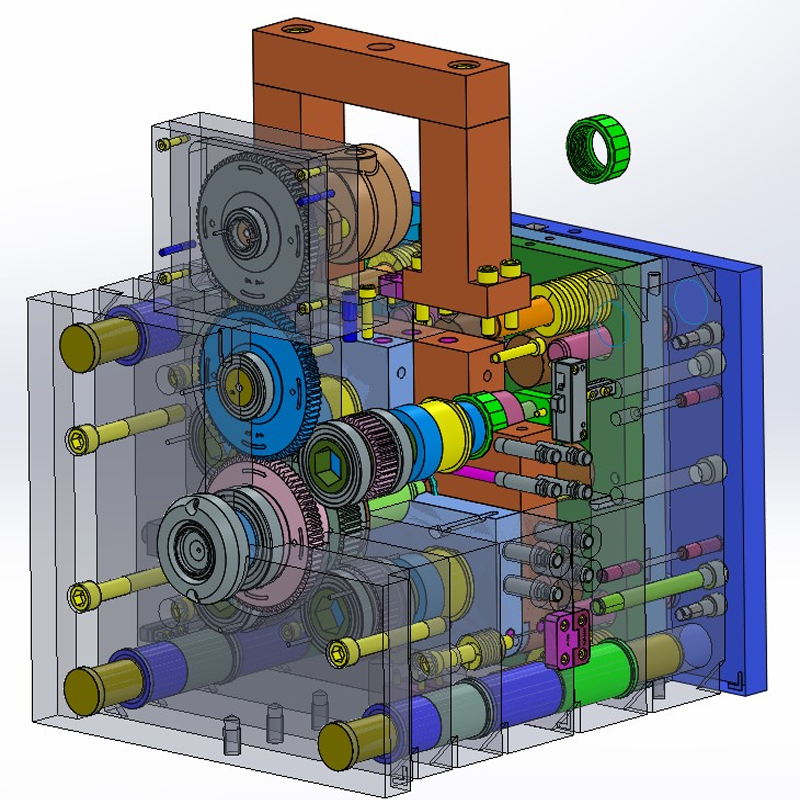

How Do Plastic Injection Molds Work and Why Do They Matter for Design?

At LSRmold, we know that many newcomers, designers, and even purchasing managers often find plastic injection molding intimidating at first glance. Questions like “What exactly is a plastic injection mold?” or “Why is mold design so critical in mass production?” come up frequently during our client consultations. As a professional factory in China specializing in […]

How Does Micro Injection Molding Compare to Traditional Injection Molding for Medical Device Production?

Injection molding has long been a cornerstone of the manufacturing process for medical devices, providing unmatched precision, repeatability, and scalability. As the demand for miniaturized and high-performance medical components continues to rise, the evolution of micro injection molding (μIM) has emerged as a game-changer in the production of smaller, highly intricate parts. At LSRmold, we […]

How Does Low Pressure Injection Molding Address Key Challenges in Electronics Manufacturing?

In the world of electronics manufacturing, protecting delicate components such as printed circuit boards (PCBs), connectors, and sensors from external environmental factors like moisture, dust, and physical damage is critical. Traditional methods like potting, conformal coatings, and hermetic sealing, although widely used, have long been recognized for their limitations. These methods often struggle to achieve […]

The Distinction Between Casting and Molding in Manufacturing Processes

While casting and molding both shape raw materials into functional parts, their methodologies, material compatibilities, and industrial applications diverge significantly. Here’s a breakdown: Molding: Precision in High-Volume Production Molding involves forming materials—typically polymers, composites, or softened metals—within a pre-engineered cavity. This process excels in creating lightweight, intricate components with tight tolerances, making it a staple […]

The Role of Steel Molds in Enhancing Plastic Injection Molding Efficiency

When selecting the right material for plastic injection molds, it’s essential to consider the specific needs of your production process, the types of parts being produced, and the quantities required. While both steel and aluminum molds have their unique advantages, at LSRmold, we have made the strategic decision to primarily use steel for our plastic […]

Mastering Polishing Techniques for a Perfect Surface Finish

At LSRmold, we understand that the surface finish of your custom-manufactured parts is crucial for both aesthetic appeal and performance. Polishing is a key finishing process used to enhance the appearance, durability, and functionality of metal components. Whether you’re in the aerospace, automotive, medical, or consumer electronics industry, a polished surface not only boosts the […]

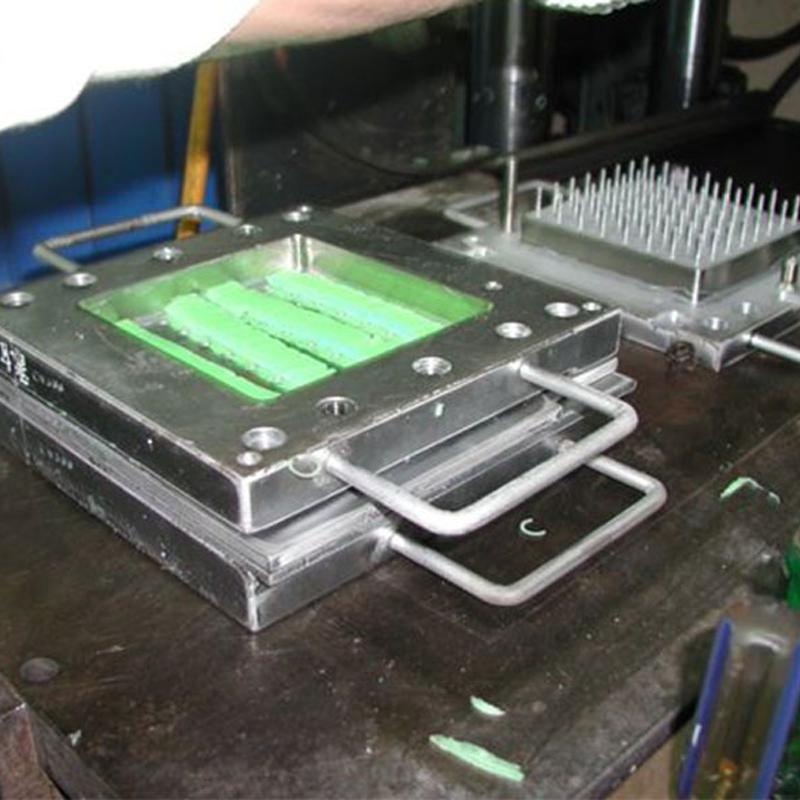

Guide To The Compression Molding Process

Compression molding is a well-established manufacturing process that is used primarily to mold high-strength, precise parts, especially with thermoset materials. This technique stands out due to its ability to create dimensionally consistent parts whether the production volume is low, medium, or high. The process involves placing a preheated material, often a thermoset plastic or rubber, […]

Key Factors That Influence the Duration of Injection Molding Processes

At LSRmold, we frequently encounter inquiries about the time it takes to complete an injection molding process. For manufacturers and product designers, understanding the cycle time is essential for streamlining production and meeting deadlines. Injection molding is a highly efficient manufacturing process, but the time required for each cycle can vary significantly based on several […]