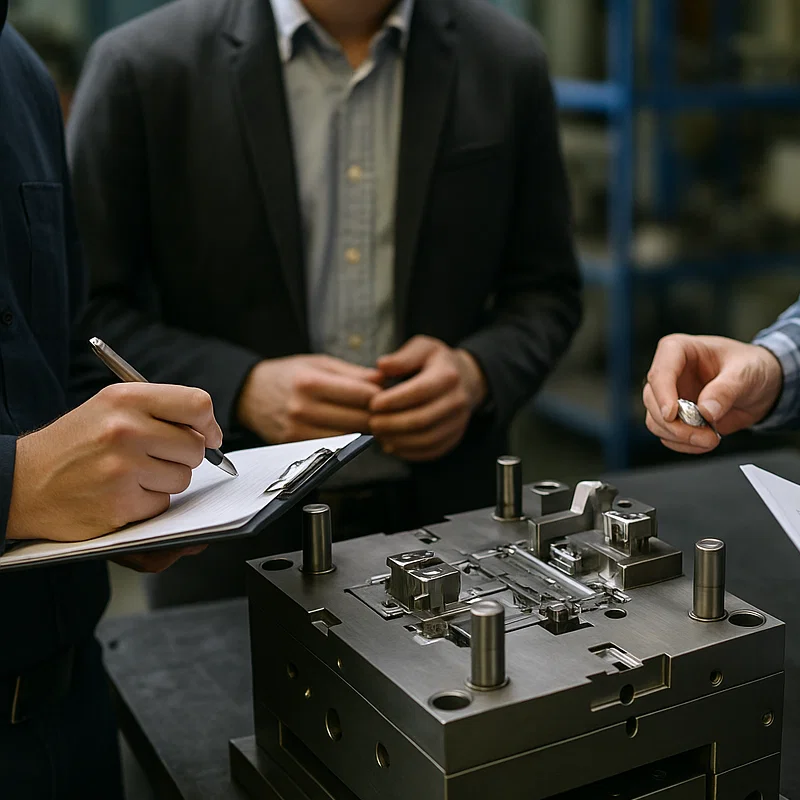

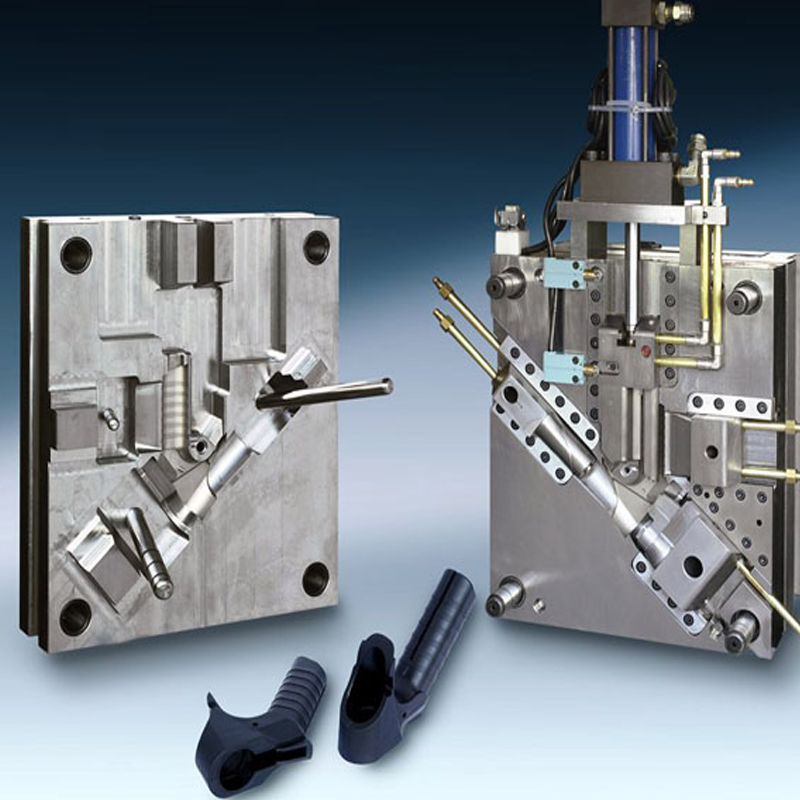

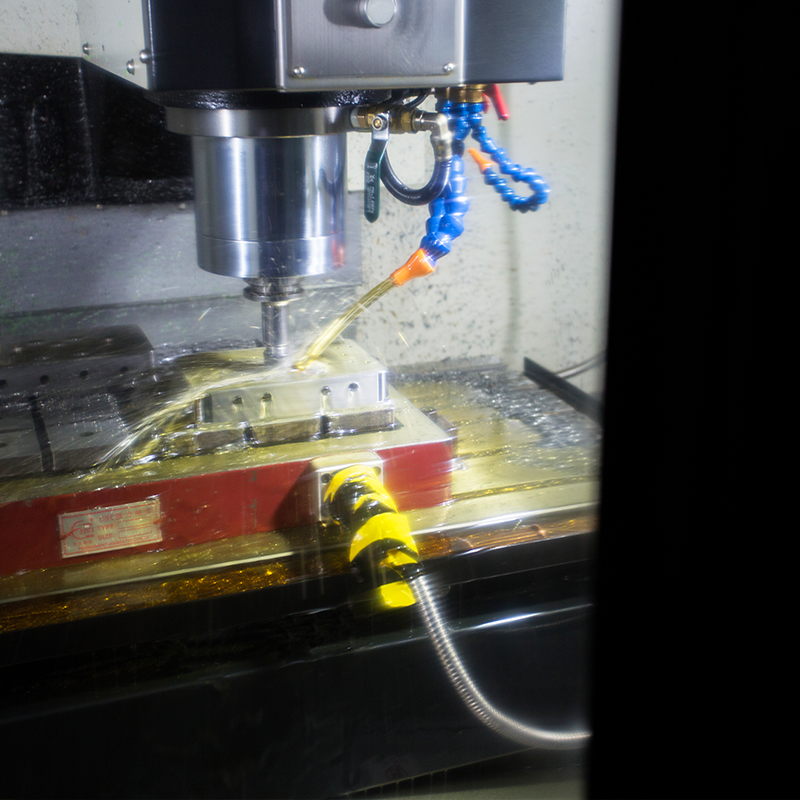

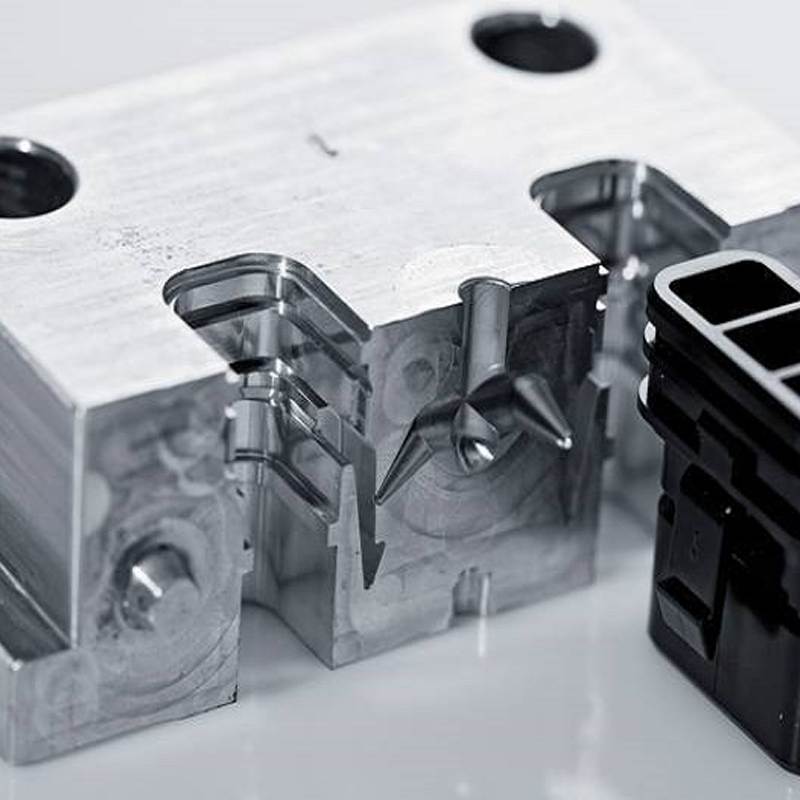

Are you racing to validate a new automotive part or trying to cut development time between prototype and production? At LSRmold, we help automotive engineers, tier suppliers, and OEMs speed product development using rapid tooling for injection molding. Below is a practical, manufacturer-focused guide that explains the top benefits of rapid tooling for automotive components, […]