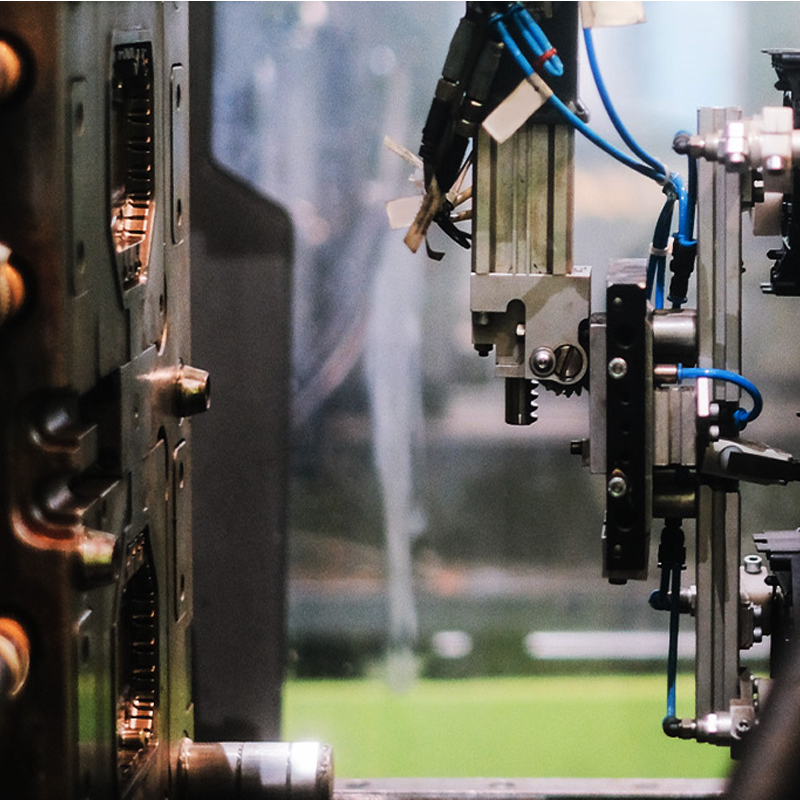

In today’s fast-paced manufacturing world, companies are constantly striving to meet the demand for lighter, more cost-effective, and sustainable production methods. Thin wall injection molding (TWIM) has emerged as a game-changing process that enables the production of plastic parts with significantly reduced wall thickness, all while maintaining strength and performance. This advanced molding technique offers […]