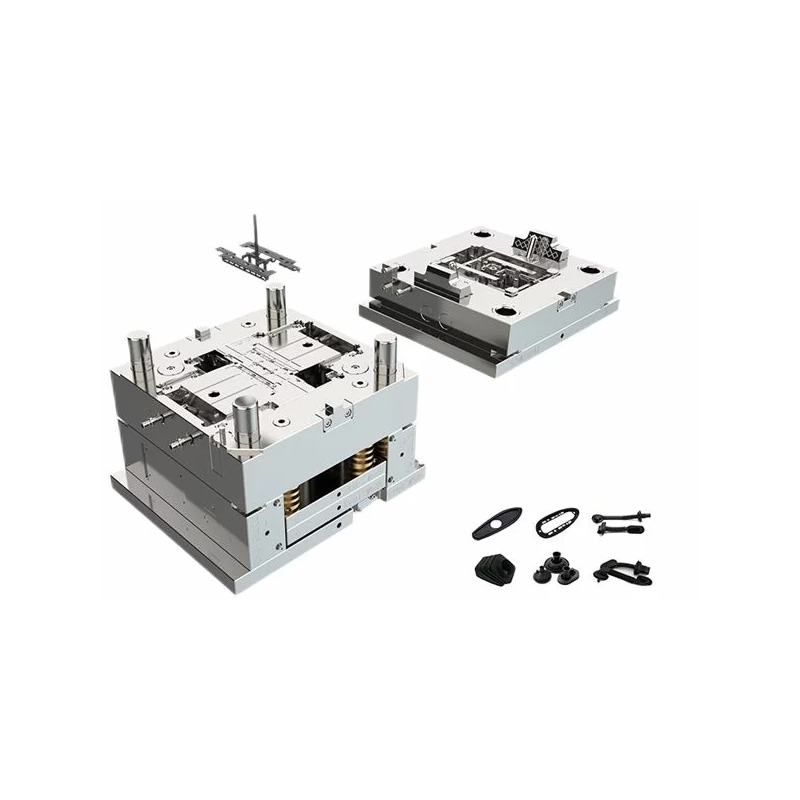

If you’re looking to master the art of plastic mold creation, you’ve come to the right place. At LSRMOLD, we specialize in producing high-quality, precision plastic molds that cater to various industries, from automotive to electronics. Whether you’re working on custom plastic parts or need to scale up for high-volume production, understanding the key steps […]