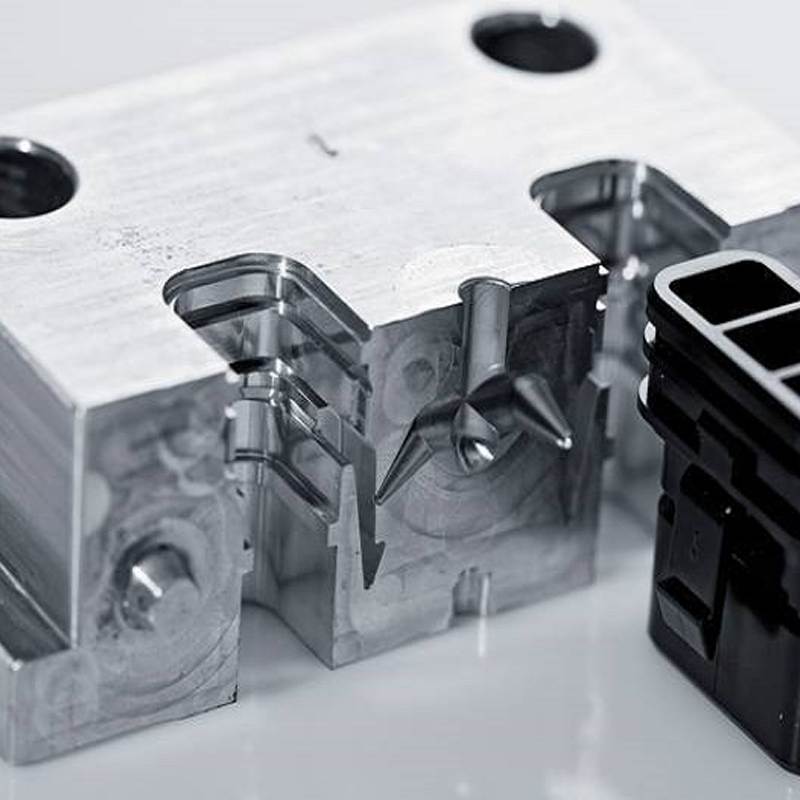

In today’s manufacturing world, companies are constantly evaluating new technologies to speed up production, reduce costs, and optimize their processes. One such advancement that has gained attention is 3D printing, specifically for creating molds for injection molding. While 3D-printed molds can offer rapid prototyping and cost-effective solutions for low-volume production, they may not always be […]