Are you frustrated by intermittent defects, late rework cycles, or inconsistent part quality from your molding supplier? At LSRmold, we hear that every day — and we build systems to solve it. In this post I’ll walk you through how modern automated quality checks are engineered into real production lines, why they’re essential for high-precision […]

Sunny

Why Use Rapid Tooling for Automotive Injection Molding?

Are you racing to validate a new automotive part or trying to cut development time between prototype and production? At LSRmold, we help automotive engineers, tier suppliers, and OEMs speed product development using rapid tooling for injection molding. Below is a practical, manufacturer-focused guide that explains the top benefits of rapid tooling for automotive components, […]

From Welding to Overmolding — A Practical Guide to Plastic Joining Methods

Are you evaluating assembly options for a new plastic product and unsure which joining method will deliver the right balance of strength, cost, and manufacturability? At LSRmold, we work with OEMs and suppliers every day to design parts that assemble reliably at volume. In this guide, written from the factory floor perspective, we’ll walk you […]

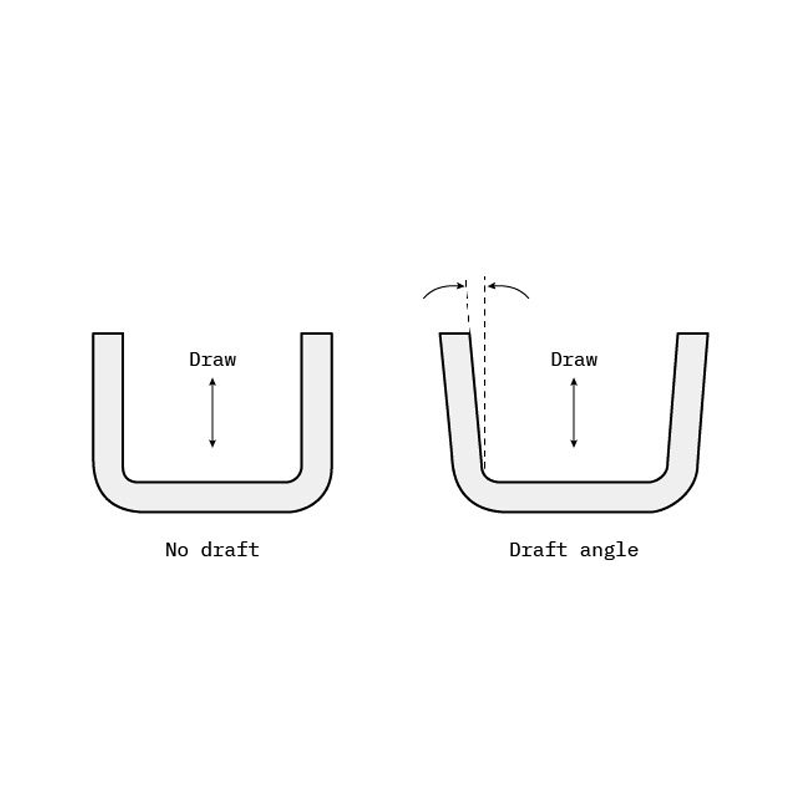

How to Design Draft Angles for Reliable Mold Release and Faster Production

When designing injection-molded components, one detail consistently separates efficient, scalable production from costly manufacturing headaches: the draft angle. At LSRmold, we’ve supported thousands of injection-molding projects across consumer goods, automotive, medical, and industrial sectors. One pattern is unmistakable—designs with proper draft angles mold cleanly, run faster, and create far fewer complications. Designs without them? They […]

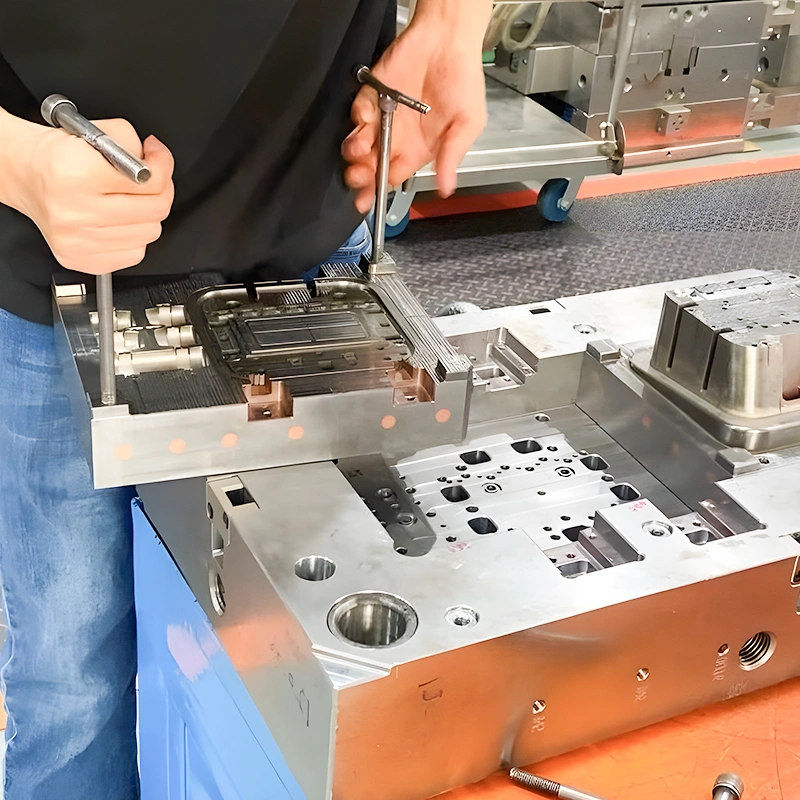

Tops Precision’s Step-by-Step Approach to Professional Mold Repairs and Upgrades

In today’s injection molding industry, the performance of your molds defines the consistency, accuracy, and long-term reliability of your production. If you are experiencing part defects, cycle time inconsistencies, or premature tooling wear, you’re not alone—these issues are common across the industry, especially as molds age or production volumes increase. At LSRmold, our team is […]

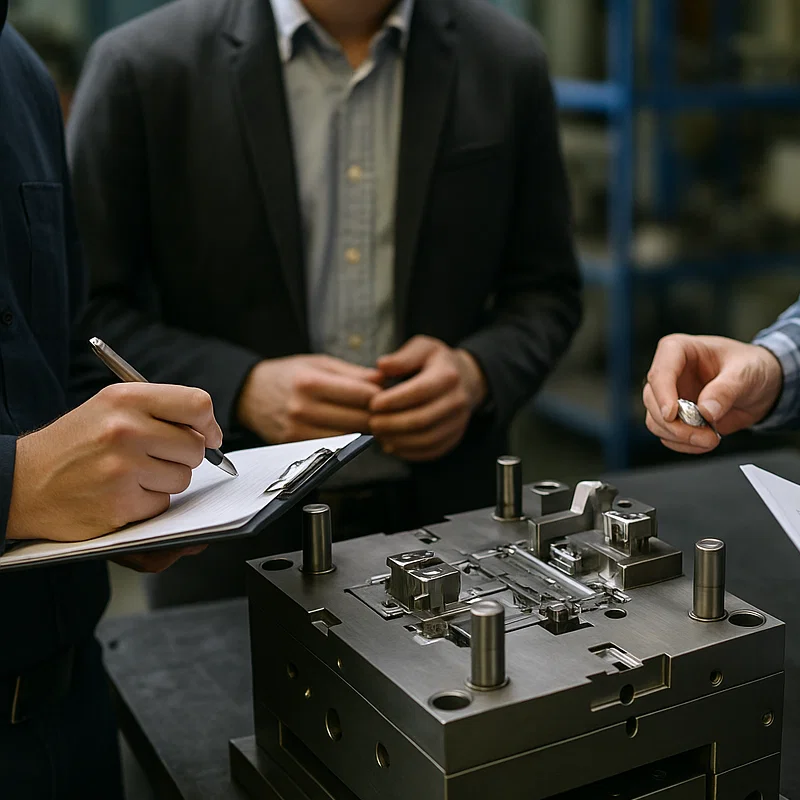

What Key Factors Should Be Considered When Choosing a Mold Supplier for Precision and Quality?

When sourcing high-quality mold-making supplies, selecting the right mold supplier is crucial to ensure the success of your project. As a leading manufacturer, LSRmold understands that choosing a professional mold supplier goes beyond simply considering pricing and delivery times. A reliable supplier must provide a complete range of mold-making products, offer precise, high-quality components, and […]

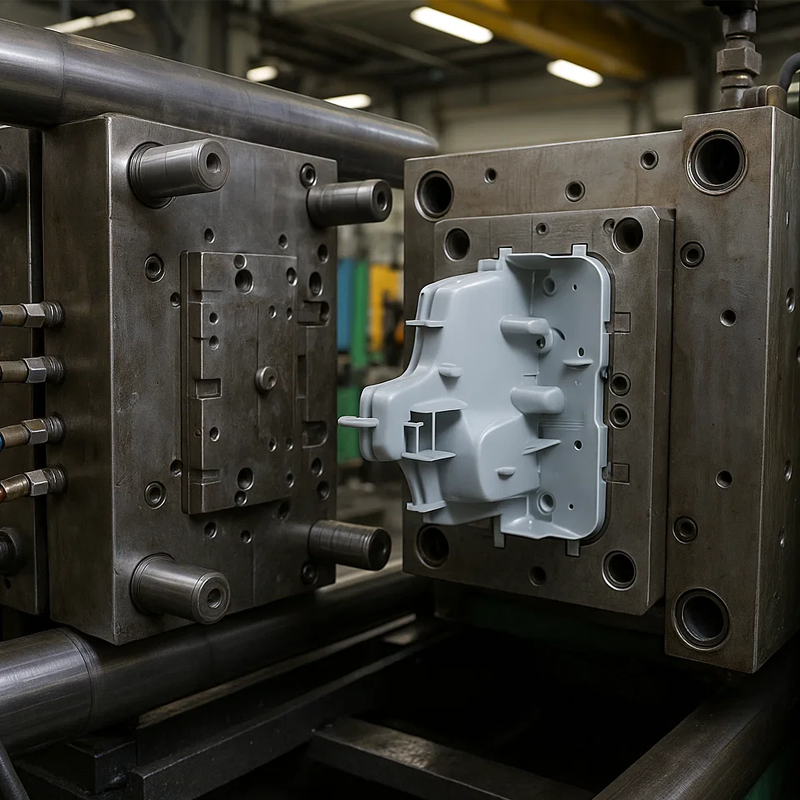

How Do Plastic Injection Molds Work and Why Do They Matter for Design?

At LSRmold, we know that many newcomers, designers, and even purchasing managers often find plastic injection molding intimidating at first glance. Questions like “What exactly is a plastic injection mold?” or “Why is mold design so critical in mass production?” come up frequently during our client consultations. As a professional factory in China specializing in […]

What Should You Know About Injection Mold Repair for Long-Term Durability?

Injection molding plays a crucial role in the production of high-precision plastic parts. It’s a process widely used across industries such as automotive, healthcare, electronics, and consumer goods. At LSRmold, we understand the complexity of injection mold systems and how critical it is to maintain them for optimal performance. This guide delves into the essential […]

How Does Micro Injection Molding Compare to Traditional Injection Molding for Medical Device Production?

Injection molding has long been a cornerstone of the manufacturing process for medical devices, providing unmatched precision, repeatability, and scalability. As the demand for miniaturized and high-performance medical components continues to rise, the evolution of micro injection molding (μIM) has emerged as a game-changer in the production of smaller, highly intricate parts. At LSRmold, we […]

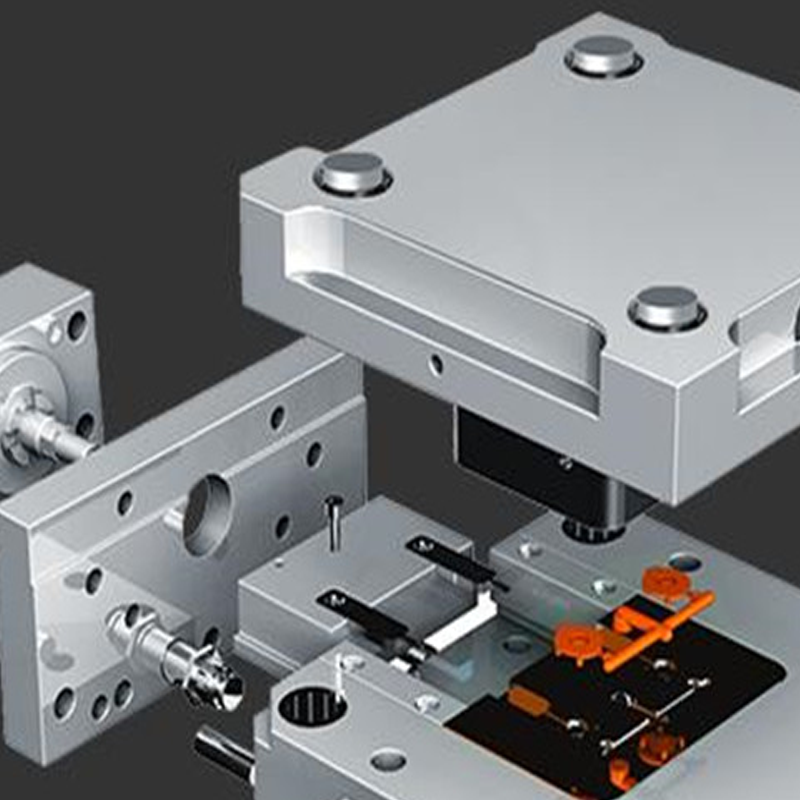

How Does Low Pressure Injection Molding Address Key Challenges in Electronics Manufacturing?

In the world of electronics manufacturing, protecting delicate components such as printed circuit boards (PCBs), connectors, and sensors from external environmental factors like moisture, dust, and physical damage is critical. Traditional methods like potting, conformal coatings, and hermetic sealing, although widely used, have long been recognized for their limitations. These methods often struggle to achieve […]