Are you racing to validate a new automotive part or trying to cut development time between prototype and production? At LSRmold, we help automotive engineers, tier suppliers, and OEMs speed product development using rapid tooling for injection molding. Below is a practical, manufacturer-focused guide that explains the top benefits of rapid tooling for automotive components, what to watch for when selecting a partner, and how smart DFM reduces risk while accelerating time to market.

5 Benefits of Automotive Rapid Injection Molding

1. Quick Alterations to Structural Designs

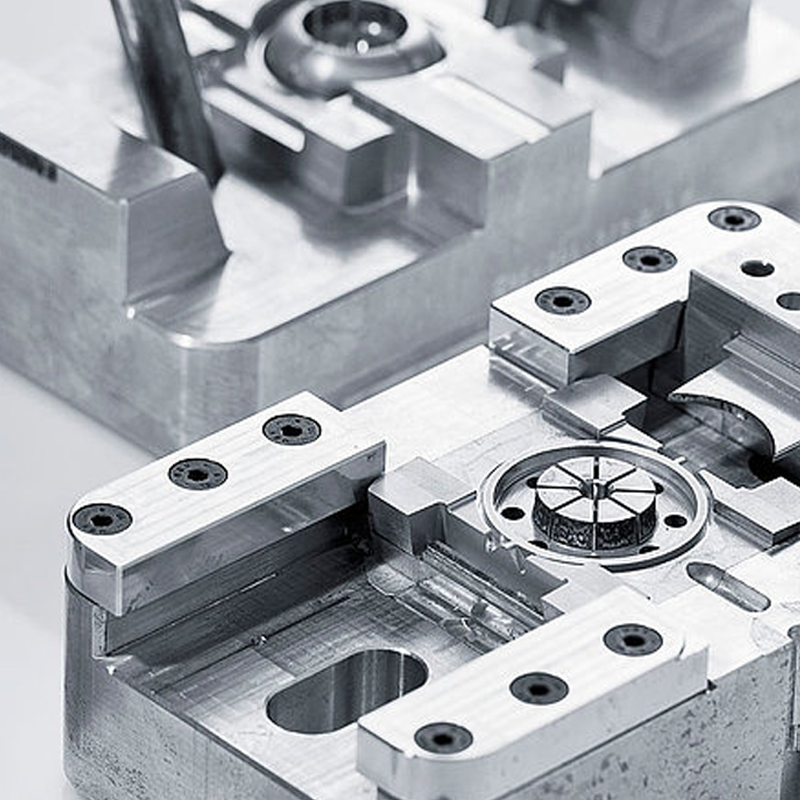

In automotive development, geometry tweaks are inevitable. Rapid tooling dramatically shortens the cycle between design change and physical validation. Because rapid tools (soft steel, aluminum, or hybrid molds) are faster and cheaper to produce than hardened production dies, you can iterate parting lines, rib patterns, boss locations, and wall thicknesses in weeks instead of months. That speed enables engineers to test multiple variants on real material and process conditions, minimizing late-stage surprises.

2. Validate the Functionality of Structural Features

CAD and CAE are essential, but only physical parts confirm real-world interactions — fit, assembly, snap-fit integrity, and tactile feel. Rapid tooling lets you produce production-like parts using the target thermoplastic (or a very close substitute) so you can validate:

- mating features with adjacent components,

- threaded bosses and insert retention,

- thin-wall fill behavior and weld-line strength, and

- cosmetic surface finish for visible trims.

This early validation reduces costly rework on production tooling and unsafe assumptions during supplier handoffs.

3. Maximizing a Limited Production Budget

Not every program needs immediate hard-tool investment. Low- to mid-volume runs, pre-launch pilot programs, and regional market tests benefit from rapid tooling’s lower upfront cost. Rapid tools reduce capital expenditure while allowing brands to meet short-run demand without paying full production-die prices. For startups or feature rollouts, this approach preserves budget for later-stage production optimization.

4. Cutting Down Production Lead Times

Traditional hardened tooling can take many months. Rapid tooling compresses that schedule significantly — tooling lead times drop from months to a few weeks in many cases. Faster tooling shortens the overall product development timeline, enabling earlier part validation, concurrent testing, and faster supplier qualification. For time-sensitive programs (facelift models, safety-critical recalls, seasonal parts), that speed can be a competitive advantage.

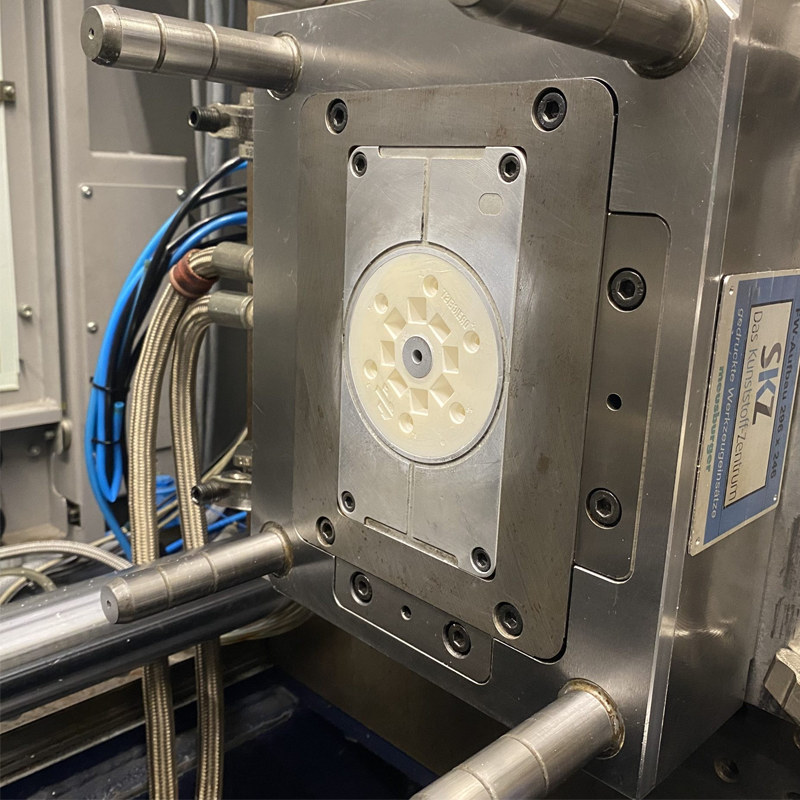

5. Flexible Transition from Automotive Prototyping to Mass Production

Rapid tooling is not a one-way street. A well-executed rapid-tooling program provides critical data — gate location, packing strategy, cooling layout, material behavior — which informs the final production die. Because you’ve already validated part geometry and processing windows, the hardened production tool can be designed with fewer unknowns, accelerating ramp-up and improving first-pass yield. In short: rapid tooling de-risks the transition to mass production.

Considerations For Choosing an Automotive Rapid Tooling Partner

When choosing a rapid tooling manufacturer or factory, evaluate these practical factors:

- Material and Process Expertise: Can the supplier run your target automotive resin (PA, PPA, PBT, PPE blends, TPO, etc.) under real process conditions? Experience with high-GF or flame-retardant grades matters.

- Tooling Portfolio & Turnkey Capability: Does the supplier offer design, machining, mold assembly, trial molding, and part finishing — a true one-stop approach with access to suppliers for inserts, fasteners, and plating?

- DFM Review and Engineering Support: Strong partners perform proactive DFM to adjust wall thickness, ribs, venting, and gate strategy to maximize yield on rapid tooling and speed validation cycles.

- Quality Systems & Documentation: Look for capability to provide inspection reports, process parameter logs, and traceability that support automotive PPAP and supplier audits.

- Cooling and Cavitation Options: Good rapid tool makers provide conformal cooling or optimized channeling when required to replicate production cooling behavior.

- Scalability Path: Confirm how the partner migrates validated parameters to hardened tooling — the ideal supplier can convert prototype lessons into production-ready designs and reduce hard-tool iterations.

Conclusion

Rapid tooling is a strategic enabler for modern automotive programs: it accelerates design validation, reduces financial risk, and improves the quality of upstream data used to build hardened production dies. At LSRmold, we pair DFM-driven engineering with rapid aluminum and hybrid tooling capabilities to help OEMs and suppliers prove designs faster and transition smoothly to production.

Want to explore whether rapid tooling suits your next automotive injection-molding project? Send us your 3D model, target material, and projected volumes. Our tooling engineers will perform a DFM review and propose a rapid-tooling plan, cost estimate, and timeline so you can validate faster and produce smarter.