Overview

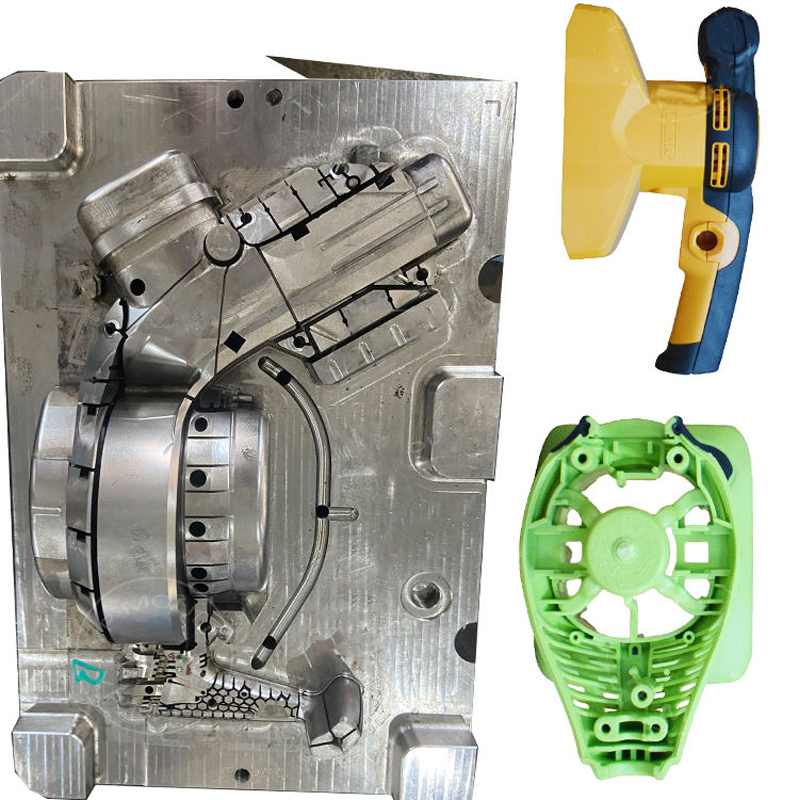

Our Custom Plastic Injection Tooling for Overmolding Electric Tools is engineered to produce durable, ergonomic components like handles, grips, and housings. Utilizing advanced CNC and EDM machining, our molds enable precise hard-soft material bonding (e.g., PC-ABS + TPE) in a single cycle, enhancing tool durability, user comfort, and assembly efficiency.

Basic Information

| Specification | Details |

|---|---|

| Mold Material | 1.2344 (H13), 1.2738 (P20+), NAK80; Stainless for corrosion-resistant inserts |

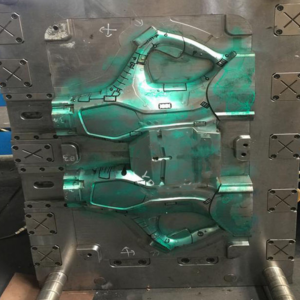

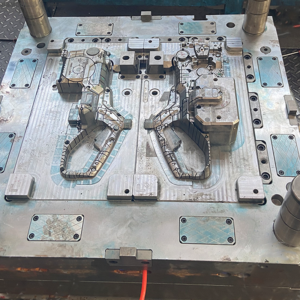

| Core Processes | 5-Axis CNC, High-Speed Milling, Mirror & CNC EDM, Precision Wire EDM |

| Molding Types | 2K/Overmold, Insert Molding, Multi-Cavity, Hot Runner Systems |

| Compatible Materials | PC, PC-ABS, ABS, PA66 (Nylon), PP; Overmold: TPE, TPU, Silicone |

| Surface Finish (Part) | Texture (VDI 3400), Grip Patterns, Fine Matte, High-Gloss Branding Areas |

| Tolerance | ±0.03 mm typical; ±0.015 mm at overmold bonding interfaces |

| Lead Time | Prototype Tooling: 12–20 days; Production Tooling: 4–8 weeks |

| Expected Tool Life | 500k – 1.5M+ shots (steel grade & coating dependent) |

| Cooling System | Conformal cooling channels optimized for both substrate and overmold materials |

| Certifications | ISO 9001:2015; IATF 16949 support; Material data sheets provided |

| OEM Services | DFM, Mold-Flow Analysis for Bonding, Prototyping, FAI & PPAP |

| Place of Origin | Xiamen, China |

Key Advantages

-

Precision Overmold Bonding Expertise: Mold engineering ensures strong, consistent chemical/mechanical bonds between rigid substrates and soft-touch overmolds, critical for tool durability.

-

Ergonomic & Functional Texturing: Advanced EDM texturing creates secure, comfortable grip patterns that enhance user control and reduce fatigue during prolonged use.

-

High-Pressure, Durable Tool Construction: Molds are built from premium steels and designed to withstand the high injection pressures and abrasive fillers (e.g., glass-filled nylon) common in power tool components.

-

Integrated Insert & Hardware Molding: Tooling designed for molding around metal inserts (threaded bosses, brass nuts), electronic housings, and internal structures, reducing post-assembly.

-

Optimized for Fast Cycling: Balanced cooling and efficient gating are engineered to minimize cycle times, essential for the high-volume production of tool components.

Surface Treatment & Decoration Options

-

VDI 3400 Standard Textures – Consistent grip textures for ergonomics and brand identity.

-

Laser Etching & Engraving – Permanent logos, rating labels, and serial numbers.

-

Two-Tone/Multi-Color Overmolding – Functional color differentiation for buttons, seals, or grip zones.

-

Soft-Touch & Anti-Slip Coatings – Enhanced urethane or silicone-based coatings for maximum grip.

-

EMI Shielding Integration – Mold design accommodates conductive shields or coatings for electronic components.

Quality Assurance

Our tooling QA follows a strict ISO 9001 protocol. We begin with DFM and comprehensive mold-flow analysis to predict and prevent bonding issues. Dimensional accuracy of cores and cavities is verified using CMM and 3D scanning. Every mold undergoes sampling trials with First Article Inspection (FAI), including tests for overmold bond strength (peel/pull tests), dimensional stability, and functional fit with tool internals. Production validation includes SPC monitoring and lifecycle testing to ensure the mold meets the rigorous durability standards of the power tool industry.

Our Factory

Our facility integrates a high-precision tooling workshop with a dedicated overmolding production cell. The workshop is equipped with 5-axis CNC centers, mirror EDM, and wire EDM machines essential for crafting intricate texture details and precise bonding surfaces. Our production floor features multi-shot injection presses with robotic arms for insert handling and precision overmolding. In-line vision systems and articulated CMMs perform automated checks. An onsite lab conducts bond-strength, drop-impact, and chemical resistance tests, ensuring every molded component meets the robust demands of professional electric tools.