Are you evaluating assembly options for a new plastic product and unsure which joining method will deliver the right balance of strength, cost, and manufacturability? At LSRmold, we work with OEMs and suppliers every day to design parts that assemble reliably at volume. In this guide, written from the factory floor perspective, we’ll walk you through the nine primary plastic-joining techniques, explain the benefits and limitations of each, and show why overmolding is often the best route when you need integrated function, superior ergonomics, and fewer assembly steps. If you want a one-stop service that includes design-for-manufacture feedback, prototyping, and full-scale production, read on — or get in touch with our team for a tailored OEM service evaluation.

Why choosing the right joining method matters

The global plastics market depends on efficient, repeatable ways to create assemblies from molded parts. The joining method you pick affects product durability, production throughput, part cost, regulatory compliance, and field serviceability. A technically correct choice can reduce downstream warranty costs and simplify your supply chain. As a factory and OEM service provider, LSRmold emphasizes early supplier collaboration to match materials, geometry, and production volume with the optimal joining approach.

1–4: Welding methods (friction & conduction-based)

Plastic welding melts the joint interface and fuses parts under pressure. These processes produce strong, often hermetic, joints without adhesives.

1. Ultrasonic Welding

How it works: High-frequency vibrations (about 20–40 kHz) focus energy at the joint (often using an energy director), melting thermoplastic locally. When vibration stops and the parts are clamped, the plastic re-solidifies into a weld.

Pros: Extremely fast cycle times, excellent for high-volume production, no consumables. Often used for housings, medical device casings, and assemblies requiring airtight seals.

Cons: Requires precise joint geometry and is limited to compatible thermoplastics. Capital investment for equipment can be high.

Factory tip: Work with your supplier to design energy directors that consistently concentrate melt where you need it.

2. Spin Welding (Rotational Friction)

How it works: One cylindrical component rotates against a stationary mating part; frictional heat melts the interface. Rotation stops, then parts are pressed together to fuse.

Pros: Strong circular joints and repeatable cycles; good for fuel caps, filters, and cylindrical housings.

Cons: Restricted to circular geometries and susceptible to flash around the weld ring.

Factory tip: If your part is not axially symmetric, don’t force this method—it will increase tooling complexity.

3. Vibration Welding (Linear Friction)

How it works: Linear oscillation under pressure melts a planar or slightly contoured joint; when motion stops, the molten layer re-solidifies under clamp force.

Pros: Flexible joint geometry and good strength for larger or irregular parts.

Cons: Longer cycle times than ultrasonic; equipment cost and part fixturing matter.

Factory tip: Vibration welding is a great compromise for larger enclosures where ultrasonic energy transfer is impractical.

4. Hot Plate Welding (Conduction Heating)

How it works: Joint faces are pressed against a heated platen until the required melt depth is reached, the platen is removed, and the faces are pressed together.

Pros: Capable of welding the widest range of thermoplastics and producing hermetic seals.

Cons: The slowest cycle time and potential for thermal degradation if parameters are not tightly controlled.

Factory tip: Use hot plate welding for high-integrity seals on tanks, ducts, and large containers where joint strength is prioritized over cycle time.

5–7: Advanced joining and molding methods

These processes bring high precision or integrate materials during molding.

5. Infrared (IR) Welding

How it works: Non-contact IR energy rapidly heats and melts the joint surface; parts are clamped to form a bond.

Pros: Clean, fast, and suitable for irregular geometries where contamination is a concern.

Cons: Requires surface preparation and precise fixturing; equipment cost is moderate to high.

Factory tip: IR welding is an excellent choice where visible aesthetics and hermetic sealing are both required.

6. Laser Welding (Through-Transmission)

How it works: A laser passes through a transmissive upper part and is absorbed by an underlying absorbing part, melting the interface.

Pros: Extremely clean welds, minimal flash, and exceptional cosmetic results. Works well for transparent-to-opaque assemblies and micro-components.

Cons: Needs specific material combinations (laser-transmissive + absorbent) and precise material control from suppliers.

Factory tip: Partner early with your LSRmold engineering team to select resin colors and additives compatible with laser transmission.

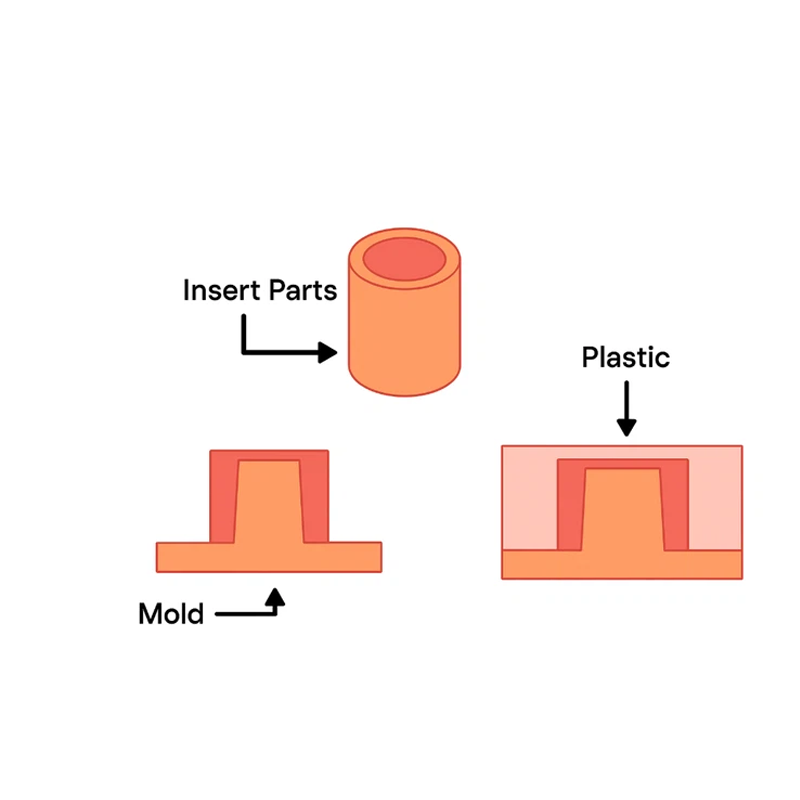

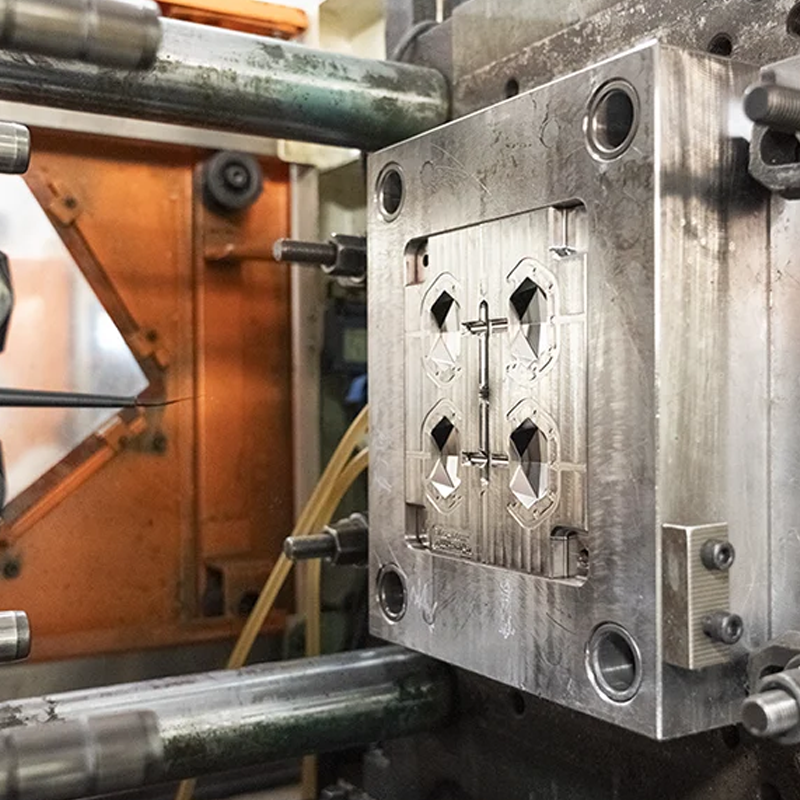

7. Overmolding (Integration, Not Assembly)

How it works: A second material, typically a soft TPE or elastomer, is injection molded directly onto a rigid substrate to form a unified part.

Pros: Eliminates secondary assembly, adds ergonomics (soft-touch grips), enhances sealing and protection of electronics, and improves aesthetics. Overmolding produces robust bonds when proper material pairings and process controls are used.

Cons: Tooling costs are higher and product design must accommodate molding flow and thermal interactions.

Factory tip: For one-stop service and high quality, LSRmold can perform substrate molding, insert placement, and overmolding in-house, reducing supplier handoffs and assembly risks.

8–9: Simple, proven methods (chemical & mechanical)

8. Solvent Bonding / Adhesive Bonding

How it works: A solvent or adhesive softens or chemically bonds polymer chains at the interface; curing completes the joint.

Pros: Low-cost and effective for geometries sensitive to heat. Useful for small batches or repairs.

Cons: Material-specific; solvent choice is critical. Curing time and environmental sensitivity can slow production.

Factory tip: When bonding dissimilar thermoplastics, adhesives designed for specific substrates often outperform welding.

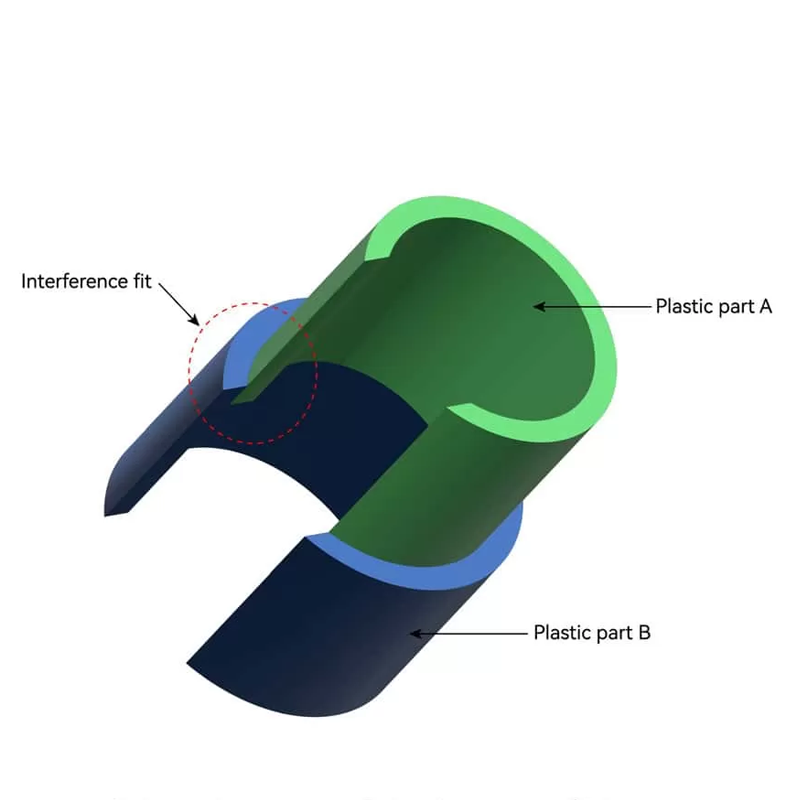

9. Mechanical Fastening

How it works: Fasteners, screws, snaps, rivets, or threaded inserts physically hold parts together.

Pros: Simple, repairable, and enables disassembly for service. Ideal for thermosets and mixed-material assemblies.

Cons: Adds components, assembly steps, and potential stress concentrators; may require inserts or boss reinforcement.

Factory tip: Design bosses and thicknesses to avoid cracking during fastener installation—our OEM service includes boss optimization.

Overmolding vs. Two-Shot (2K) Molding — what’s the difference?

Overmolding is typically a sequential process: the rigid substrate is molded first, removed, and placed into a second mold for the soft component. Two-shot (2K) molding accomplishes both materials in a single automated cycle by rotating or translating the part between cavities. The trade-off: 2K yields higher throughput and tighter registration but requires more complex tooling and higher capital costs. LSRmold advises customers on which path fits their production volumes and long-term cost targets.

Practical selection advice from the factory floor

- Match material families for welding whenever possible to maximize joint strength.

- Design energy directors for ultrasonic welding early in the CAD stage.

- Consider overmolding if you want to reduce assembly steps, add function, and improve aesthetics.

- For dissimilar plastics or thermosets, plan on adhesives or mechanical fastening.

- Engage your supplier early — tooling, material selection, and process choice are interdependent. LSRmold’s one-stop service reduces iterations and speeds time-to-market.

Final thoughts

Choosing the right joining technique is a commercial and engineering decision that impacts product performance, assembly cost, and supply-chain complexity. At LSRmold, we deliver high quality by combining design support, prototyping, and full-scale manufacturing under one roof. Our OEM service and factory capabilities let us recommend the best approach — whether that’s ultrasonic welding for speed, laser welding for cosmetic-critical parts, or overmolding for integrated functionality.

If you’re designing a product that must balance ergonomics, durability, and manufacturability, let our team review your design. We work with suppliers and contract partners to provide a true one-stop service that moves projects from concept to high-quality production. Contact LSRmold today for a consultation and a targeted, practical manufacturing plan.