Overview

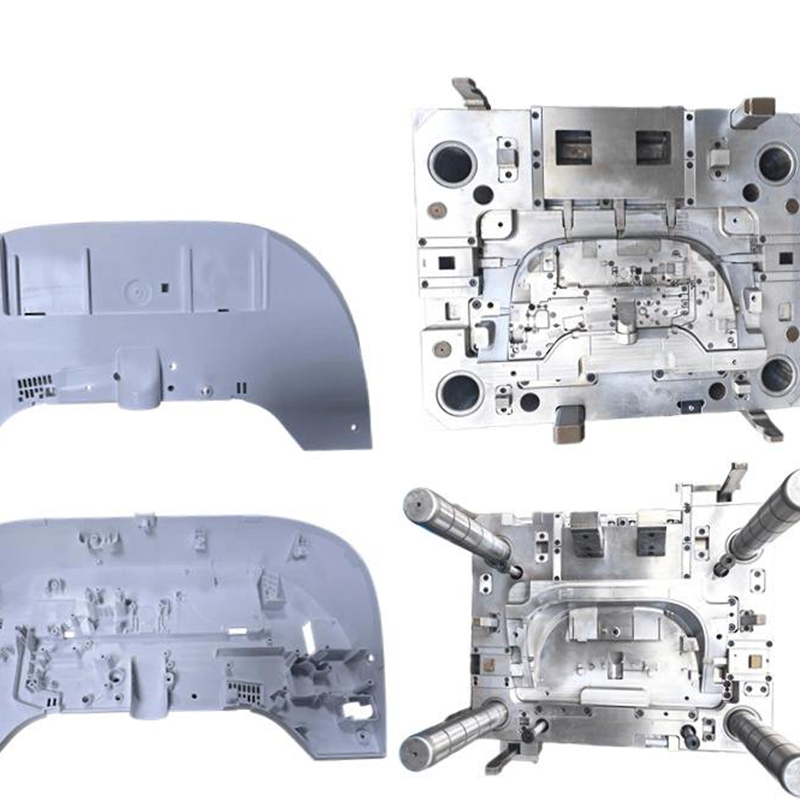

The Custom Precision Plastic Injection Mold Tooling for Bathroom Covers (Sanitary Ware & Household) is engineered to produce high-quality, cosmetically perfect plastic covers and trim components for toilets, bidets, faucet escutcheons, shower trims, vanity hardware, drain covers, and related sanitary fixtures. Our tooling supports thin-wall molding, tight cosmetic tolerances, multi-cavity layouts, insert and overmold features, and post-process-ready surfaces (high-gloss, chrome-look, soft-touch) to meet the aesthetic and durability demands of bathroom products while enabling efficient seasonal or continuous production runs.

Basic Information

| Specification | Details |

|---|---|

| Mold Material | P20, H13, S136, SKD61; Aluminum 7075 for prototype tooling |

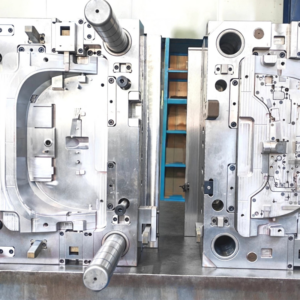

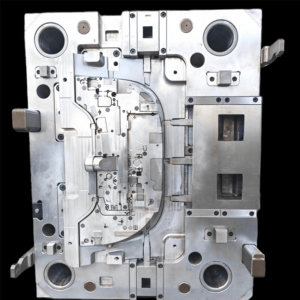

| Core Processes | 5-axis CNC, high-speed milling, mirror EDM, WEDM/slow wire cutting, precision grinding |

| Molding Types | Single- to multi-cavity (1–8 cavities typical), hot-runner, cold-runner, family molds, insert molding, 2K/overmold |

| Compatible Materials | ABS, PC, PC/ABS, PP, POM, PMMA (acrylic), SAN, TPU (for soft seals), TPE |

| Surface Finish (part) | Mirror gloss, satin/soft-touch matte, anti-fingerprint; SPI A1–A3 polish grades; micro-textures |

| Tolerance | ±0.02 mm typical; ±0.01 mm available for critical sealing/assembly features |

| Lead Time | Prototype tooling: 10–18 days; Production tooling: 3–8 weeks (tool complexity dependent) |

| Expected Tool Life | 200k–1M+ shots depending on steel grade, coating and maintenance |

| Wall Thickness | Thin-wall designs down to 0.6 mm (material dependent) |

| Temperature & Cycle | Thermally balanced toollines for short cycle times; conformal cooling as option |

| Certifications | ISO 9001; support for RoHS / REACH and material compliance testing |

| OEM Services | DFM, mold-flow simulation, prototype samples, trial shots, FAI / PPAP documentation |

| Place of Origin | Xiamen, China |

Key Advantages

- Sanitary-Grade Cosmetic Quality — precision gate placement, mirror-polished faces and controlled micro-textures provide flawless visible surfaces ready for plating, painting, or printing.

- Thin-Wall & Fast Cycle Expertise — tooling engineered for thin-wall parts with optimized cooling channels and fast cycle performance to lower per-piece cost.

- 2K & Overmold Capability — integrated tooling for hard/soft overmolds (PC/ABS + TPE) to produce sealed trims, comfortable grips and integrated gaskets in a single cycle.

- Insert & Hardware Integration — supports threaded brass inserts, metal brackets, magnets, and snap-fit bosses placed during molding to reduce downstream assembly.

- Tight Functional Tolerances — precision machining and cavity control for snap-fits, hinges, threaded interfaces and water-seal surfaces that meet installation requirements.

- Durable Tooling & Long Runs — hardened steel options, PVD / nitriding coatings and optimized runner systems for stable shot counts across high-volume production.

- Cost-Effective Cavity Balancing — cavity layouts and hot-runner systems designed to minimize imbalance, reduce waste, and scale for seasonal demand.

Surface Treatment & Decoration Options

- Vacuum Metallization / Chrome-Look Coating — high-reflective finishes for premium faucets and trim.

- Electroplating-ready Mold Surfaces — mirror polish and controlled release to support secondary plating processes.

- High-Gloss Mirror Polish (SPI A1) — premium gloss for visible covers and lids.

Quality Assurance

All tooling is manufactured and validated under an ISO 9001 quality-management system. Early-stage DFM and mold-flow analysis reduce risk prior to machining. Dimensional control uses ZEISS CMM and 3D optical scanning; surface roughness is measured by profilometer. Each mold undergoes trial runs and a First Article Inspection (FAI) that includes dimensional reports, cosmetic verification, shrinkage validation, thermal balancing checks and functional tests (snap-fit, hinge action, sealing surfaces). Production validation includes run-life sampling, SPC monitoring, and accelerated wear testing to confirm tool performance over expected shot counts. Material certificates, inspection reports and traceability documents are provided with deliveries.

Our Factory

Our tooling and molding campus pairs advanced CNC and EDM capability with dedicated plastic injection lines tailored for sanitary-ware components. Key assets include multi-axis CNC centers, mirror and conventional EDM, precision grinding, robotic polishing cells and conformal-cooled tool builds. We run multiple injection presses with hot-runner and 2K/overmold capability, robotic part handling, in-line vision inspection and controlled curing/aging stations. Secondary services include vacuum metallization, painting, pad printing, ultrasonic welding and automated assembly lines for inserts or hardware. An onsite testing lab supports thermal cycling, dimensional verification, torque/load testing for snap-fits and salt-spray/coating adhesion checks — all managed by experienced tooling engineers and QA specialists to deliver turnkey solutions from prototype to high-volume production.