Overview

Our Customized High-Precision Injection Mold Tooling for Silicone & Plastic Festival Promotion Gift Parts is engineered to deliver eye-catching, durable, and cost-effective promotional items for seasonal retail and brand campaigns. Designed for parts such as mascot toys, glow-in-the-dark gifts, soft-touch keychains, novelty lights, and multi-material promo items, these tools support single- and multi-shot molding, LSR/LSR + plastic overmolding (2K), and insert/assembly features that speed time-to-market while ensuring consistent cosmetic quality and reliable cycle life.

![]()

![]()

Basic Information

| Specification | Details |

|---|---|

| Mold Material | P20, H13, S136, SKD61; Aluminum 7075 for prototype tooling |

| Core Processes | 5-axis CNC, high-speed milling, mirror EDM, WEDM/slow wire cutting, precision grinding |

| Molding Types | Single-cavity to multi-cavity (1–16 cavities typical), hot-runner, cold-runner, 2K / overmold, insert molding |

| Compatible Materials | LSR / silicone, TPE, TPU, ABS, PC, PP, PS, PMMA, PC/ABS blends |

| Surface Finish (part) | Mirror polish, soft-touch matte, textured patterns (SPI standards) |

| Tolerance | ±0.02 mm typical; ±0.01 mm available for critical features |

| Lead Time | Prototype tooling: 10–20 days; Production tooling: 3–7 weeks (tool complexity dependent) |

| Expected Tool Life | 100k–1M+ shots depending on steel grade and surface treatments |

| Temperature & Cycle | Designed for fast cycles; dedicated LSR hot-sprue or cold-runner gating for silicone parts |

| Certifications | ISO 9001:2015; support for RoHS / LFGB / FDA compliance on materials |

| OEM Services | DFM, mold-flow simulation, rapid prototyping, trial shots, FAI / PPAP documentation |

| Place of Origin | Xiamen, China |

Key Advantages

- Multi-Material & Multi-Shot Expertise — integrated tooling for LSR + rigid plastic overmolding (2K) produces soft-touch features, bonded logos, and sealed electronics in one cycle.

- Cosmetic & Decorative Focus — precision gate placement, mirror polish, and micro-texturing ensure blemish-free visible faces ready for pad or screen printing, glow pigments, or laser etching.

- Fast Prototyping to Mass Production — aluminum prototype tools for quick validation; hardened steel production tools for long runs with predictable lead times.

- Tight Cosmetic Tolerances — controlled shrinkage and precision machining deliver consistent part geometry for snap-fits, threaded inserts, and assembly interfaces.

- Design for Assembly — integrated features for snap-fits, press-in magnets, LEDs or battery housings; tooling supports low-force de-molding for delicate electronics.

- Cost-Effective Volume Scaling — balanced cavity layouts and hot-runner systems minimize cycle time and reduce per-piece cost for seasonal volume spikes.

Surface Treatment & Decoration Options

- Mirror Polishing (SPI A1) — high-gloss surfaces for premium gift finishes.

- Soft-Touch Texturing — matte tactile surfaces for pleasant hand-feel on toys and keychains.

- PVD / Nitriding / Hard Chrome — extended tool life for abrasive colorants or high-shot runs.

- Laser Etching / Pad Printing / Screen Printing — permanent logos, Pantone color matching, multi-color graphics.

- Glow & Phosphorescent Inserts — tooling prepared for pigment inserts or co-molding glow compounds.

Quality Assurance

All molds are manufactured and validated under an ISO 9001 quality system. Pre-machining DFM and mold-flow analysis reduce risk before tool build. Dimensional control is verified with ZEISS CMM and 3D optical scanning; surface roughness measured by profilometer. Each mold undergoes trial runs and First Article Inspection (FAI) including dimensional reports, cosmetic checks, shrinkage verification, and functional tests (snap-fit, hinge action, overmold bond). Production lots can be supplied with traceability records, run-out sampling, and accelerated life testing to validate tool performance over expected shot counts.

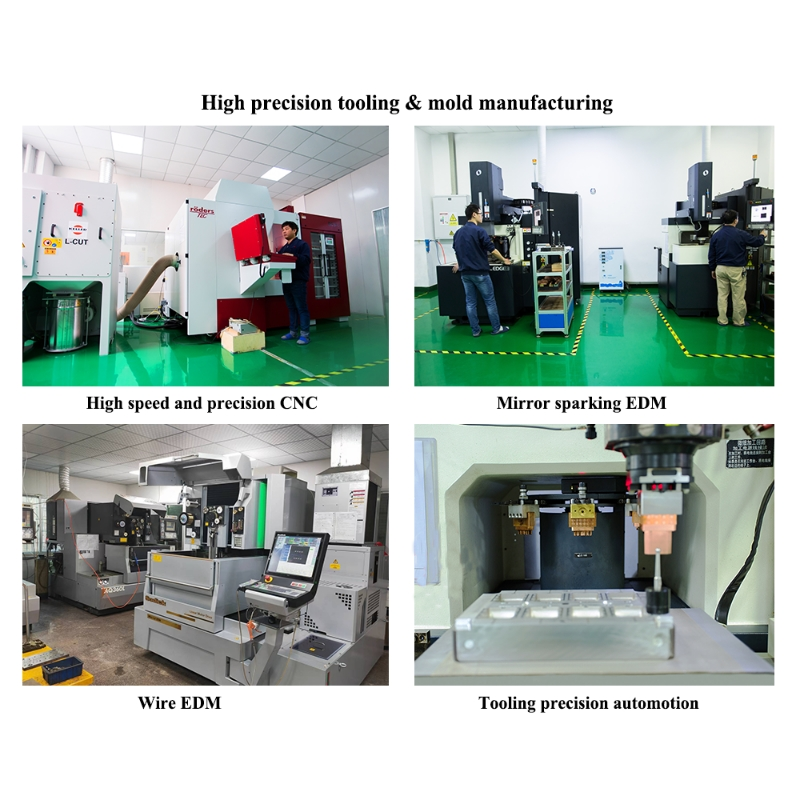

Our Factory

Our tooling shop features high-precision 5-axis CNC machining centers, high-speed mills, mirror and conventional EDM, and wire-cut capability for complex core/cavity geometries. Robotic polishing cells and controlled polishing rooms ensure repeatable mirror finishes and soft-touch textures. We operate dedicated LSR injection and silicone compression molding lines alongside conventional plastic injection presses for seamless 2K/overmold trials. In-house decoration lines include pad printing, laser etching, and controlled curing ovens. Final assembly labs handle simple electronics integration, LED testing, and retail packaging. With experienced tooling engineers and full CAD/CAM/CAE support, we deliver turnkey solutions from prototype samples to seasonable mass production.