Are you frustrated by intermittent defects, late rework cycles, or inconsistent part quality from your molding supplier? At LSRmold, we hear that every day — and we build systems to solve it. In this post I’ll walk you through how modern automated quality checks are engineered into real production lines, why they’re essential for high-precision manufacturing, and how our factory integrates these tools with DFM and custom service offerings to deliver a true one-stop solution for OEMs and manufacturers.

What “Automated Quality Checks” Really Means

Automated quality checks are the factory-grade systems that inspect, validate, and document part quality without relying on manual sampling. They combine sensors, machine vision, dimensional metrology, process analytics and software into a continuous feedback loop that watches every cycle — not just occasional samples. The goal is simple: catch issues sooner, correct them automatically or immediately escalate them, and provide a fully auditable record of every shot for traceability and regulatory compliance.

Key components include:

- In-mold and process sensors (pressure, cavity temperature, injection speed) for process-window monitoring

- Machine-vision systems for cosmetic defects and color/texture inspection

- 3D laser scanning and inline CMM for critical dimensional verification

- Edge computing + MES / SPC for real-time analytics, alarms, and closed-loop adjustments

- Data logging and traceability so every part links back to machine, tool, material batch and operator

Why Automated Inspections Are Non-Negotiable Today

Modern products — from medical devices to EV connectors — demand tolerances and consistency that manual inspection cannot reliably guarantee at scale. Here’s why manufacturers are standardizing on automated checks:

- Repeatability: Machines don’t tire. They apply the same measurement criteria thousands of times per shift.

- Speed: Inspections occur inline, often in milliseconds to seconds, so production doesn’t stall waiting for QA.

- Traceability & Compliance: Regulated industries require documented process data; automation provides full digital records.

- Lower Scrap & Faster Root Cause: Defects are detected immediately, enabling process correction rather than scrapping entire lots later.

- Scale: Automated systems scale with volume; you can run millions of parts with the same inspection rigor as a prototype run.

At LSRmold, our customers expect high quality and predictable output — and automation is how we deliver that promise across OEM and custom service work.

How LSRmold Implements Automated Quality Control — Practical Architecture

We design inspection strategies to match part criticality, cycle time, and production volume. Below is our standard layered approach:

1) Process-level Controls (Real-time)

We place pressure, temperature and cavity sensors in the tool and tie them into the machine controller and MES. If a parameter drifts outside the DFM-defined window, the system will either auto-adjust parameters or stop the shot and quarantine parts for review. This prevents short shots, flash, and sink before they become a run-wide problem.

2) Visual Inspection (Machine Vision)

High-resolution cameras — including 2D and structured-light 3D vision — capture every part for surface defects (flash, burn marks, discoloration, flash, gate issues). AI-driven classifiers distinguish acceptable variation from true defects, reducing false rejects. We calibrate vision systems per material/color because optical properties vary widely with LSR, colored plastics, and textured surfaces.

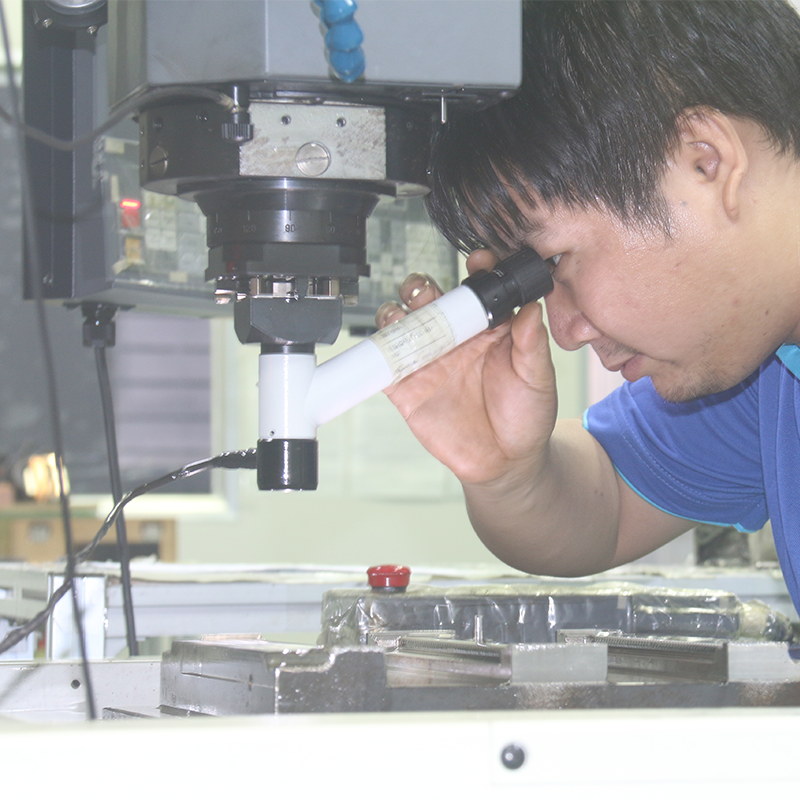

3) Dimensional Verification (Inline Metrology)

Critical dimensions are measured with laser triangulation or inline CMM stations. For high-precision features we use multi-probe or scanning systems that compare each part to CAD tolerances in real time. Parts that deviate are automatically flagged and routed.

4) Data Analytics and SPC

All inspection and process data feed our SPC dashboards. Trending identifies drift (tool wear, material lot shifts, cooling issues) before it produces nonconforming parts. Predictive alerts schedule maintenance or tooling changes when patterns indicate upcoming failures.

5) Traceability & Reporting

Every part is assigned a unique identifier (barcode/RFID), tying inspection results back to the injection machine ID, tool cavity, resin lot, and operator. That audit trail is included in delivery packages when required by customers in medical, automotive, and aerospace sectors.

Real Benefits — What Customers Actually See

When automated quality checks are applied correctly, the benefits are tangible:

- Reduced scrap and rework — typical reductions range from 30% to 70% depending on baseline performance and defect drivers.

- Higher first-pass yield — fewer interrupted runs and less manual rework.

- Shorter lead times — less time spent fixing defect cascades and faster approvals.

- Stronger compliance posture — instant access to production data during audits or supplier qualification.

- Better DFM outcomes — data enables iterative tool and design refinements that prevent future issues.

(At LSRmold we quantify these gains per program during onboarding and include continuous improvement KPIs in our custom service agreements.)

Industry Use Cases Where Automation Matters Most

- Medical devices: zero-defect expectations and regulatory traceability make automated inspection essential.

- Automotive & EV: critical connectors and housings require micrometer tolerances and validated supplier data.

- Consumer electronics: cosmetic consistency and fit across high volumes demand machine-vision grading.

- Aerospace & defense: parts must meet strict certification; automated logs and dimensional proofs are mandatory.

Practical Challenges & Best Practices

Automation isn’t plug-and-play — success depends on engineering rigor and operational discipline:

- Material optics: shiny or translucent materials need tailored lighting and algorithms. We prototype vision setups early during DFM reviews.

- Calibration & maintenance: sensors and cameras need scheduled recalibration to avoid drift. Our maintenance plans include automated health checks and calibration logs.

- False rejects: initially common with naïve AI models. We train models on representative production data and maintain a human-in-the-loop escalation to refine classification.

- Cycle time vs. inspection resolution: very high-resolution checks can extend cycle times. We balance per-part inspection with statistical inline sampling for non-critical features.

- Integration: seamless data exchange between machine controllers, MES and ERP is required; LSRmold provides full systems integration as part of our one-stop service.

Investing in Automated QA: ROI and Program Onboarding

Most customers see payback from automated inspection through lower scrap, fewer warranty returns, and reduced manual inspection labor. We run a formal ROI model during quoting that includes:

- Baseline scrap and rework costs

- Expected reduction percentage from automation

- Cost of inspection equipment, integration and training

- Payback horizon and projected lifetime savings

LSRmold’s engineers manage end-to-end: from DFM optimization and prototyping to pilot lines and full production rollout — a true OEM-grade, one-stop service for manufacturers seeking high quality at scale.

Final Thoughts — Let’s Make Your Next Run Predictably Excellent

If your program struggles with intermittent defects, inconsistent color, or you need FDA/ISO traceability, automated quality checks are not a luxury — they’re a requirement. At LSRmold, we combine deep injection-molding experience with data-driven inspection design to give you consistent parts, documented traceability, and the operational efficiency modern products demand.

Contact our team for a complimentary DFM review and a customized inspection plan. Whether you need low-volume prototyping or high-volume OEM runs, our factory delivers custom service, high quality, and a one-stop manufacturing partnership that scales with your business.