Overview

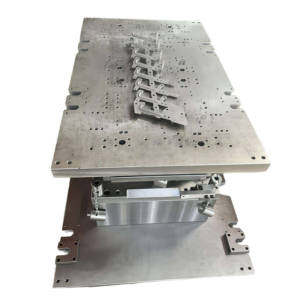

Our Custom CNC Precision Machining Stamping Die and Progressive Punching Mold Tooling are engineered specifically for high-volume production of car instrument-panel connect brackets and related fastening hardware. Combining multi-station progressive die design with CNC-machined tooling components and precision EDM finishes, our molds deliver tight tolerances, consistent strip feeding, and repeatable part quality. Designed for integration with progressive stamping lines, the tooling supports secondary forming (bending, coining, flaring), in-die tapping or clinching, and is optimized for long tool life in automotive production environments.

Basic Information

| Specification | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Tool Type | Progressive Stamping Die / Progressive Punching Mold |

| Typical Part Materials | Cold-rolled steel, stainless steel (301/304), HCS, spring steel, brass |

| Die Steel Grades | P20, D2, SKD11, H13 (as specified) |

| Tolerance (parts) | ±0.01 mm (critical features) / ±0.02 mm (general) |

| Press Compatibility | 50–800 ton progressive presses |

| Tool Life (typ.) | 500,000 – 2,000,000 strokes (depending on material & maintenance) |

| Sample Lead Time | 10–15 days |

| Tooling Lead Time | 4–8 weeks |

| OEM Support | Full design, DFM, tryout, and maintenance training |

| Certifications | ISO 9001, IATF 16949 |

| Packaging | Wooden crate with anti-rust and shock protection |

Key Benefits

- High-precision progressive dies for consistent bracket geometry and fast line speeds.

- Integrated secondary operations (bend, coin, clinch, in-die tapping) reduce post-process time.

- Long tool life with hardened inserts and optimized wear zones for low total cost of ownership.

- Turnkey service from CAD/DFM through tryout, PPAP, and serial supply readiness.

Production Process

- Design & DFM — CAD/CAE evaluation with strip layout, blanking sequence, and coil utilization analysis.

- CNC Machining & EDM — High-accuracy cavitation/matrix machining, mirror EDM for punch faces and die cavities.

- Heat Treatment & Surface Hardening — Nitriding, quench & temper to achieve targeted die hardness and wear resistance.

- Assembly & Tryout — Bench assembly, press tryout with sample runs, die adjustment and cycle optimization.

- Validation & PPAP — First Article Inspection (FAI), capability studies, dimensional reports and PPAP documentation.

- Production Support — Spare parts kit, in-field maintenance training, and die refurbishing services.

Surface Treatment Options

- Zn / Ni Electroplating — Corrosion protection and lubricity for long tool life.

- Black Oxide / Phosphate — Improved adhesion for lubricants and anti-rust properties.

- Nitriding — Hardened surface for improved wear resistance on punch & die faces.

- PVD Coatings (TiN, CrN) — Low friction and extended life for high-wear areas.

Quality Assurance

We enforce stringent QA protocols for automotive tooling:

- Material certification and incoming steel inspection.

- Dimensional verification using CMM, optical projectors and laser scanners.

- Finite Element & Moldflow analysis for strip stresses and springback prediction.

- Process control with SPC during tryout and production runs.

- Complete PPAP package including FAI, control plans, and traceability logs.

Our Factory

Equipped with multi-axis CNC centers, precision wire EDM, mirror EDM, high-accuracy grinders and a dedicated stamping die assembly shop, we support full in-house tooling manufacture, tryout, and refurbishment. Our facility includes progressive press cells for validation, a plating line for surface treatments, and an accredited metrology lab for part and tool verification. ISO 9001 and IATF 16949 certified, we deliver automotive-grade tooling ready for series production.