Overview:

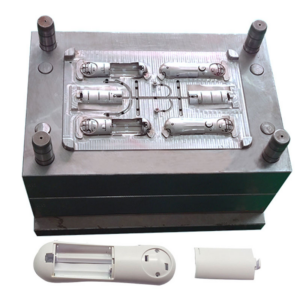

Our factory specializes in designing and manufacturing Custom Professional High Precision Medical Grade Injection Tooling Moulds, engineered for the demanding requirements of healthcare and life sciences applications. Constructed from premium-grade tool steels such as stainless steel (420SS, 316L) and medical-grade hardened alloys, these molds are processed with state-of-the-art CNC machining, EDM, and precision grinding to achieve micron-level accuracy. Optimized gating and venting systems ensure clean molding with zero flash, meeting the strictest dimensional tolerances required for critical medical devices. All tooling is produced in ISO Class 7 cleanroom environments, ensuring biocompatibility and contamination-free production. Our one-stop OEM service includes mold design, prototyping, validation testing, and scalable mass production—delivering reliable solutions for syringes, IV connectors, surgical instrument handles, and microfluidic components.

Basic Information:

| Specification | Details |

|---|---|

| Material Options | Medical-Grade Stainless Steel (420SS, 316L), Hardened Tool Steel (H13), Aluminum Alloy (7075) |

| Sample Lead Time | 10–20 days |

| Production Lead Time | 4–6 weeks |

| Process | CNC Machining, Mirror EDM, Precision Wire EDM, High-Speed Milling |

| Surface Finish | Polished, Textured, or Mirror Finish (Ra ≤ 0.4 μm for optical/medical clarity) |

| Cleanroom Standard | ISO Class 7 cleanroom tooling and validation |

| Customization | Full OEM Support—Design, DFM, Prototyping, Mass Production |

| Certifications | ISO 13485, ISO 9001, IATF 16949, FDA, RoHS, CE Compliance |

Benefits of Our Mold:

- Ultra-High Precision Machining

Multi-axis CNC and micro-EDM deliver ±0.002 mm dimensional accuracy, critical for microfluidics, syringe barrels, and implant-grade components. - Medical-Grade Cleanroom Production

Tooling is manufactured and validated under ISO Class 7 cleanroom conditions, minimizing risks of particulate contamination in medical-grade plastics. - Optimized Mold Performance

Advanced cooling channel design ensures cycle-time reduction by up to 25% while maintaining stable dimensional integrity and minimizing part stress. - Surface Integrity & Biocompatibility

Polished cavity surfaces achieve mirror finishes (Ra ≤ 0.4 μm), ensuring smooth, defect-free molding that complies with USP Class VI and ISO 10993 biocompatibility standards.

Surface Treatment Options:

- Chromium Nitride (CrN) Coating – Enhances wear resistance and prevents sticking with high-temperature polymers like PEEK and PSU.

- Diamond-Like Carbon (DLC) Coating – Provides ultra-low friction, anti-sticking performance for precision medical micro-parts.

- Polished Mirror Finish – Achieves clarity and smooth surfaces ideal for optical and transparent medical components.

- Passivation Treatment – Increases corrosion resistance and ensures full biocompatibility for stainless-steel-based tooling.

Quality Assurance:

Our quality-assurance system for medical-grade injection molds follows ISO 13485 and FDA QSR requirements. Each mold undergoes rigorous validation, including dimensional accuracy checks (±0.002 mm tolerance verified with ZEISS CMM and Keyence 3D scanners), surface roughness testing, and endurance simulations across >1,000,000 molding cycles. Environmental testing includes high-temperature aging, sterilization (EtO, autoclave, gamma), and chemical-resistance trials against medical-grade polymers. Our traceability framework ensures batch-level tracking, backed by ISO 9001:2015-certified quality management and fully documented PPAP validation protocols.

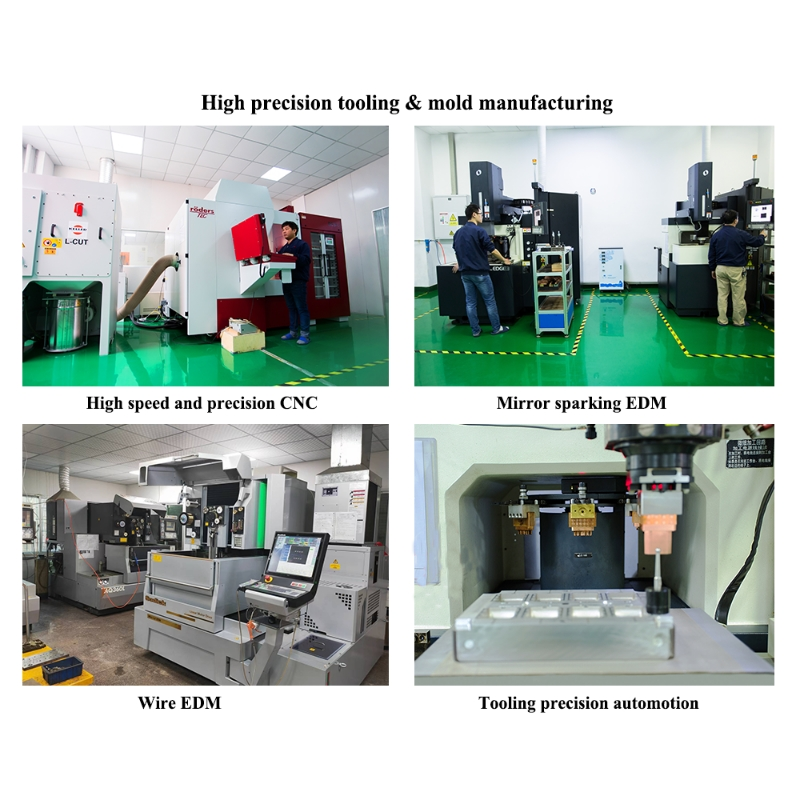

Our Factory:

Equipped with over 20 high-precision CNC machining centers, 10 mirror EDM units, and advanced wire-cut EDM systems, our facility is designed for ultra-precision medical tooling production. We integrate CAD/CAE/CAM systems for DFM optimization, mold-flow analysis, and cycle-time efficiency. With ISO 13485-certified cleanroom environments, we offer full end-to-end tooling and molding services for Class I, II, and III medical devices. Automated inspection systems—including 3D optical scanners, contact profilometers, and CMMs—guarantee flawless quality control. By combining technical expertise, stringent quality assurance, and scalable production capacity, we deliver world-class medical tooling solutions that ensure patient safety and regulatory compliance.