Overview:

The Customized Medical Grade High Precision Injection Tooling Mold for Silicone Medical and Dental Parts is a state-of-the-art solution designed for the precise and efficient manufacturing of high-quality silicone medical and dental components. These molds are meticulously crafted from premium materials such as hardened steel or aluminum alloys, using advanced CNC machining and EDM (Electrical Discharge Machining) processes to achieve the highest levels of precision. With our deep expertise in medical-grade tooling, we provide fully customized solutions that meet the stringent requirements of the medical industry, ensuring the highest quality and performance standards. Our molds are designed to meet ISO 13485, FDA, and other relevant certifications, ensuring compliance with regulatory standards and delivering parts that are safe, reliable, and durable for use in medical and dental applications.

![]()

![]()

Characteristics

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Product Material | Hardened Steel (e.g., NAK80, S136), Aluminum Alloys |

| Mould Design Software | UG, PROE, SOLIDWORKS, CAD, etc. |

| Sample | Available upon request |

| Certification | ISO 9001, IATF 16949, ISO 13485 |

| Runner System | Hot Runner or Cold Runner |

| MOQ | Based on your requirements |

| Lead Time | 25-30 business days for mass production |

| Surface Treatment | Nickel Plating, Hard Anodizing, Polishing |

| Packaging | Custom Packaging Solutions |

| Technology | CNC Machining, EDM, Injection Molding |

Benefits of Our Tooling

- Uncompromising Precision:

The use of CNC machining and EDM processes ensures that the molds are manufactured with ±0.005mm tolerance, guaranteeing high accuracy and flawless component production for complex silicone medical and dental parts. - Durable Material Selection:

Molds are fabricated using hardened steel (e.g., NAK80, S136) or aluminum alloys, offering exceptional wear and corrosion resistance. This ensures the molds can withstand 500k+ injection cycles, significantly reducing maintenance and downtime. - Optimized Cycle Time Efficiency:

Our molds are equipped with conformal cooling channels and hot runner systems, optimizing the cycle time and reducing overall energy consumption by up to 30%. This results in faster production rates without sacrificing part quality. - Regulatory Compliance & Safety:

Our molds are designed to meet the highest medical industry standards such as FDA, ISO 13485, and RoHS. Each mold is equipped with appropriate venting systems to ensure optimal material flow and part integrity, providing safe, non-toxic finishes suitable for medical and dental applications.

Surface Treatment Options

- Nickel Plating:

Provides superior corrosion resistance, improving the mold’s longevity and protecting it from wear, which is especially critical for high-precision molds used in medical devices. - Hard Anodizing:

Increases the mold’s surface hardness, enhancing wear resistance and ensuring that molds maintain their precision over extended production runs. - Polishing:

Improves the surface finish of the mold, reducing friction during the molding process, ensuring high-quality finishes on the silicone parts, and preventing any potential imperfections or defects.

Quality Assurance

Our Custom Medical Grade High Precision Injection Tooling Molds are subject to a rigorous, multi-step quality control process to ensure that each mold meets the highest standards for medical-grade production. We follow ISO 9001 and IATF 16949 certification requirements, ensuring compliance with the latest FDA and ISO 13485 standards. Our quality process includes the following stages:

- Incoming Material Inspections:

All raw materials used for mold production undergo a detailed inspection to confirm their suitability for medical applications. - In-Process Monitoring:

Throughout the manufacturing process, we utilize coordinate measuring machines (CMM) and hardness testers to verify dimensional accuracy and material properties. - Final Product Evaluation:

Every mold undergoes extensive testing to verify its performance, including surface roughness analysis, electrical conductivity, and functional testing to ensure flawless operation in medical device manufacturing.

Why Choose Us?

- Expert Medical Tooling Knowledge:

With years of experience in medical-grade tooling, we provide high-precision molds that meet the most demanding requirements of the medical and dental industries. - Comprehensive Customization:

We offer tailored solutions, including custom mold designs, material choices, and surface treatments, to ensure that our molds meet your exact specifications. - Cutting-Edge Manufacturing Technology:

Our facility is equipped with the latest CNC machining, EDM, and injection molding technologies, ensuring exceptional mold precision and optimal part performance. - Certified Quality Assurance:

Our ISO 9001 and IATF 16949 certifications ensure that each mold meets rigorous quality standards, delivering safe, reliable, and high-performance molds for medical and dental applications.

Contact Us Today to learn more about our Custom Medical Grade High Precision Injection Tooling Molds for silicone medical and dental parts. Let us provide you with the highest-quality tooling solutions designed for your specific applications in the medical industry.

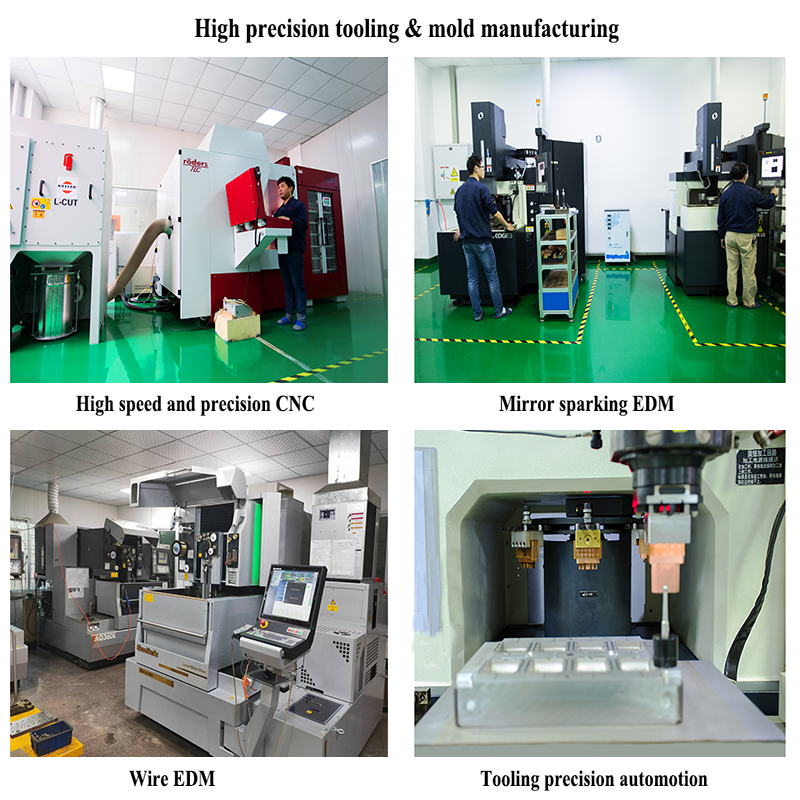

Factory Show

Our state-of-the-art manufacturing facility is equipped with cutting-edge machinery and technologies to ensure the highest precision and quality in tooling mold production. We employ advanced CNC machining to achieve ultra-precise mold cavity machining with tolerances of ±0.005mm, ensuring flawless fit and function for silicone medical parts. Our use of EDM (Electrical Discharge Machining) technology allows for intricate features, sharp edges, and small cavities, delivering unparalleled accuracy and smooth surface finishes for complex parts. In addition, we utilize injection molding with hot runner systems and conformal cooling channels to optimize cycle times and enhance part quality. Our dedicated inspection and quality control team utilizes 3D optical projectors, sealing testers, durometers, and elasticity gauges to verify mold performance, ensuring that each mold produces parts with the utmost precision and durability. We are fully committed to maintaining our ISO 9001 and IATF 16949 certifications, upholding the highest standards in medical device manufacturing.