Injection molding plays a crucial role in the production of high-precision plastic parts. It’s a process widely used across industries such as automotive, healthcare, electronics, and consumer goods. At LSRmold, we understand the complexity of injection mold systems and how critical it is to maintain them for optimal performance. This guide delves into the essential techniques and best practices for injection mold repair, offering insights that can help you extend the life of your molds while maintaining the quality of your products.

What Is Injection Molding and Why Is It Critical?

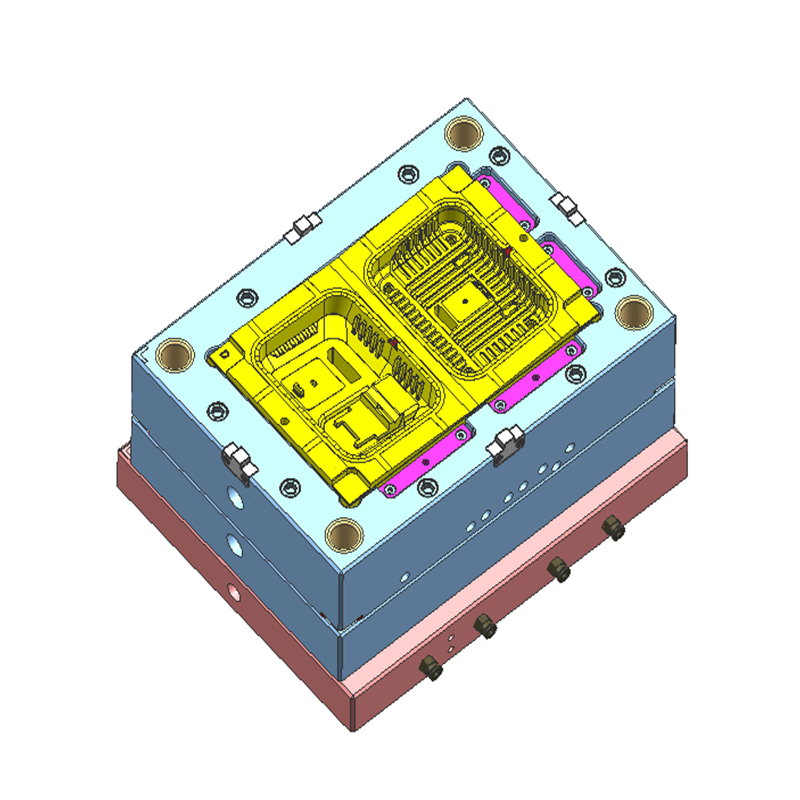

Injection molding is a manufacturing process used to produce parts by injecting molten plastic into a mold. The process begins with heating solid plastic pellets to a liquid form. The liquid plastic is then injected at high pressure into a mold cavity where it cools, solidifies, and takes the shape of the cavity. The mold consists of two main parts: the core and the cavity. The precision of this mold enables the creation of complex shapes with tight tolerances, making injection molding an essential part of modern mass production.

At LSRmold, we have extensive experience in mold manufacturing and repair. We provide one-stop service for companies needing high-quality, custom-designed injection molds. Whether it’s a minor repair or a complete overhaul, our skilled technicians can help extend the life of your molds and ensure high-quality production.

Common Issues That Can Lead to Injection Mold Repair

Like all manufacturing equipment, injection molds wear down over time, especially with prolonged use. Several common issues can arise, affecting both the mold’s performance and the final product’s quality:

- Wear and Tear: Over time, mold parts such as the cavity, core, and ejector pins degrade due to high stress, leading to poor-quality parts or the need for repairs.

- Porosity: This is the formation of undesirable patterns, marks, or unevenness on the surface of the final part, often caused by improper material flow or mold contamination.

- Misalignment: Poor alignment of the core and cavity can lead to flash formation and other defects that degrade the mold’s efficiency and the part’s quality.

At LSRmold, we understand these challenges and specialize in resolving them. Our custom service and manufacturing expertise ensure that your molds are restored to optimal functionality, minimizing downtime and production losses.

Signs That Your Injection Mold Needs Repair

Molds often display clear signs that maintenance is required. Early detection can help avoid costly repairs or even the need for a mold replacement. Key indicators include:

- Flash Formation: Flash is a visible sign of material leakage at the parting line. It typically occurs due to mold misalignment or wear of mold components. Flash formation is not only unsightly but can also affect the usability of parts.

- Surface Imperfections: Marks, dents, and uneven surfaces on molded parts often indicate that the mold is either worn out or damaged. Surface imperfections are often caused by wear on the cavity or contamination, which disrupts material flow and cooling.

- Ejector Pin Issues: If parts become difficult to eject or show marks from the ejector pins, it’s a sign of wear on the ejector system. Worn-out pins can cause parts to remain stuck to the mold, leading to production delays.

- Dimensional Inaccuracies: When molded parts are out of tolerance, it indicates mold wear or degradation. This could involve issues with the cavity, core, or the guiding system, which may need adjustments or repairs.

- Increased Cycle Time: Any significant increase in cycle time can signal mold problems, such as inefficiency in the cooling system or misalignment, leading to higher operational costs and decreased productivity.

By identifying these issues early on, you can save time and money by performing necessary repairs rather than waiting until the mold is completely compromised.

Essential Tools for Injection Mold Repair

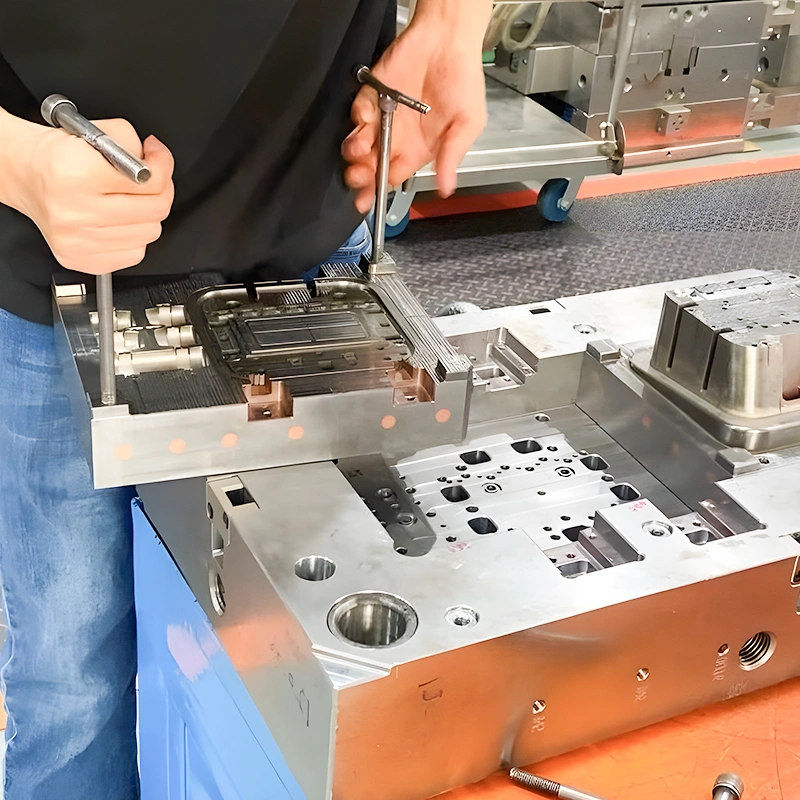

Repairing injection molds requires precision and the right set of tools. Here’s a look at some of the key equipment used to keep molds in top shape:

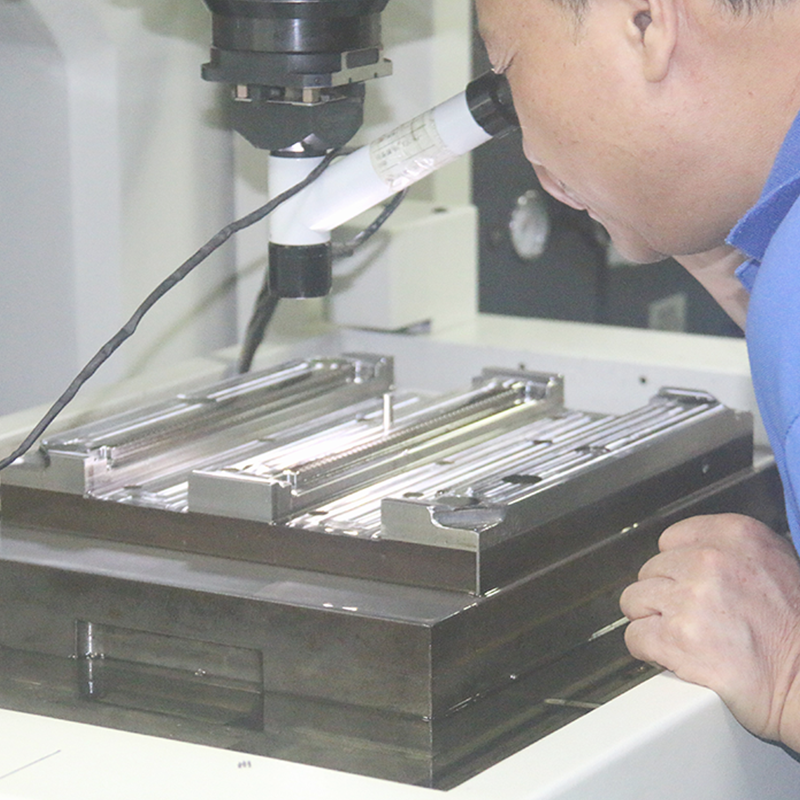

- Precision Grinding Machine: Used to correct surface imperfections and improve the finish of mold cavities and cores.

- Welding Equipment: Essential for repairing cracks or damaged mold surfaces by applying micro-TIG or laser welding techniques.

- Polishing Tools: Tools like diamond paste and polishing stones are used to smooth out rough spots, scratches, and marks.

- Measuring Instruments: Devices like calipers and micrometers are crucial for inspecting mold dimensions and ensuring accuracy after repairs.

- Ejector Pin Removal Tools: Specialized tools for removing and replacing worn-out ejector pins.

- Cooling System Diagnostic Tools: Essential for diagnosing and clearing blockages in the cooling channels, which is critical for maintaining optimal cycle times.

At LSRmold, we use the best tools and techniques to ensure that every repair we perform is done to the highest standard, guaranteeing a smooth and efficient mold.

Step-by-Step Injection Mold Repair Techniques

Several repair techniques can restore the functionality and extend the life of your injection molds. Here are the most common methods:

- Welding and Patching: When a mold has cracks or surface damage, welding and patching can restore the damaged area. Using precision welding techniques such as micro-TIG welding, we apply a clean weld to the affected area, ensuring minimal distortion and maximum repair integrity.

- Surface Grinding: Surface grinding removes small amounts of material from worn-out mold areas. Using a precision grinding machine, we can restore a smooth and level surface, improving the mold’s overall functionality.

- Component Replacement: When a part of the mold, such as an ejector pin or guide pin, is too worn out to be repaired, it needs to be replaced. At LSRmold, we carefully disassemble and replace faulty components to restore the mold’s performance.

- Reconditioning Cores and Cavities: This process involves grinding, polishing, or even welding the core and cavity of the mold to restore their original dimensions. It is especially critical for molds that produce intricate or high-tolerance parts.

Evaluating Mold Repair vs. Replacement

When deciding whether to repair or replace a mold, several factors must be considered. If the damage is minor, repairs are usually cost-effective and extend the life of the mold. However, in cases of severe damage—such as deep cracks or significant misalignment—it may be more cost-effective to replace the mold entirely.

The decision also depends on the frequency of required repairs. If the cost of repairing a mold exceeds 50-60% of the cost of a new mold, replacement may be the better long-term solution. Additionally, if production volumes are increasing or if the mold design is changing, investing in a new mold may be more beneficial for overall efficiency.

Conclusion: Maintaining Your Molds with LSRmold

At LSRmold, we specialize in providing high-quality manufacturing and custom solutions for injection mold repair. Our expert technicians are skilled in diagnosing mold issues and performing repairs that extend the life of your equipment, ensuring minimal disruption to production schedules. Whether you need minor repairs, reconditioning, or a complete mold overhaul, we offer one-stop service tailored to your specific needs.

If you’re experiencing issues with your injection molds or want to optimize their performance, contact us today. Our team will work with you to find the most effective and cost-efficient solution for your manufacturing needs. Let us help you keep your molds in top condition for better productivity and product quality.