Injection molding has long been a cornerstone of the manufacturing process for medical devices, providing unmatched precision, repeatability, and scalability. As the demand for miniaturized and high-performance medical components continues to rise, the evolution of micro injection molding (μIM) has emerged as a game-changer in the production of smaller, highly intricate parts. At LSRmold, we specialize in both traditional and micro injection molding, offering high precision and custom services to meet the unique needs of the medical industry. In this blog, we’ll explore the key differences between micro and traditional injection molding, and how manufacturers can make informed decisions when choosing the appropriate molding process for medical applications.

Introduction to Injection Molding in Medical Devices

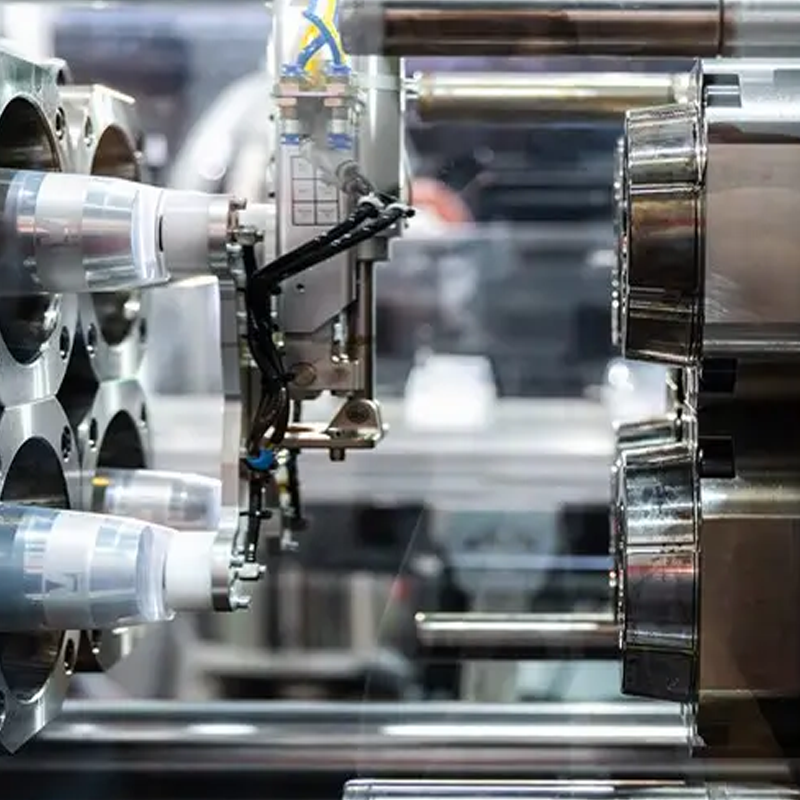

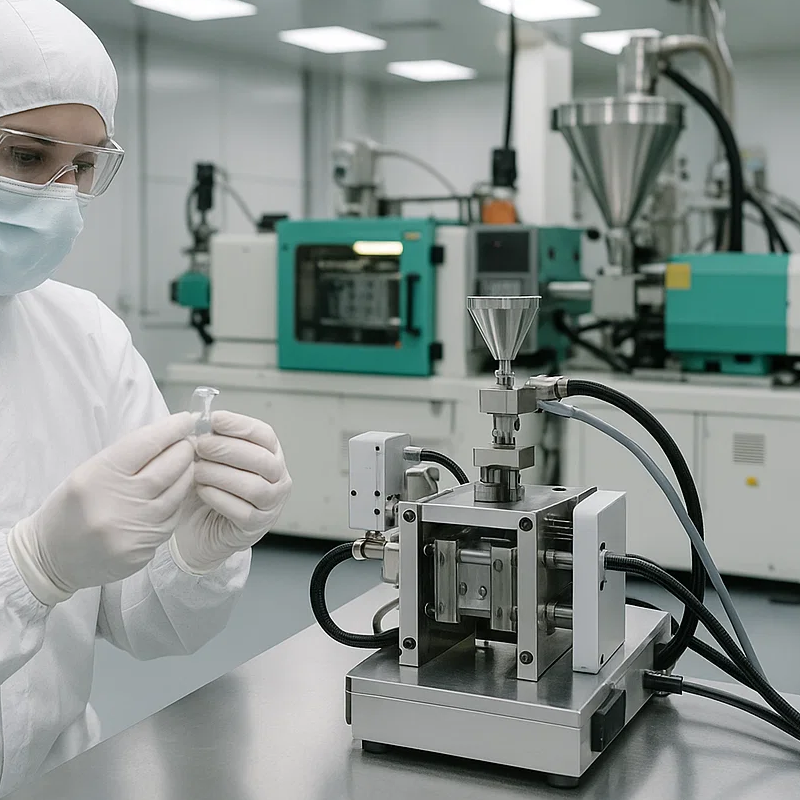

Medical devices often require components that are not only complex but also made to strict tolerances, biocompatible, and produced under sterile conditions. Injection molding is the ideal solution for producing these components, and it is widely used to manufacture parts like catheters, surgical instruments, drug delivery systems, and diagnostic equipment. However, as the trend toward miniaturization continues, especially for minimally invasive and implantable devices, micro injection molding is gaining increasing traction.

As a trusted manufacturer and supplier specializing in both traditional and micro injection molding, LSRmold is uniquely positioned to provide a one-stop service for the medical sector. From prototyping to full-scale production, our high-precision molding services are designed to meet the rigorous demands of medical device manufacturing.

Defining Traditional vs. Micro Injection Molding

To understand the differences between traditional injection molding and micro injection molding, let’s first define each process:

- Traditional Injection Molding: This process typically involves the production of plastic parts that weigh over 1 gram and have tolerances of ±0.05 mm or more. Traditional molding is commonly used for larger medical components where cost-effectiveness and high throughput are key factors.

- Micro Injection Molding (μIM): Micro injection molding, in contrast, is defined by:

- Part weights of less than 1 gram, often under 0.1 g

- Feature sizes in the micrometer range

- Tolerances as tight as ±0.005 mm

- Shot weights as low as a few milligrams

Micro injection molding is used for ultra-small components such as microfluidic devices, microneedles, and micro-optics in advanced diagnostic and therapeutic applications.

Key Differences Between Micro and Traditional Molding

At LSRmold, we leverage both traditional and micro injection molding to meet the diverse needs of the medical device industry. Below are the primary differences between these two processes:

1. Tooling and Mold Design

- Traditional Molds: Traditional molds often use standard steel alloys and are designed with multi-cavity layouts to accommodate larger part sizes and higher-volume production. These molds typically have a rougher surface finish, which is adequate for most larger medical parts.

- Micro Molds: Micro molds are crafted using high-precision steel alloys and require advanced machining techniques such as electrical discharge machining (EDM), laser ablation, and micro-milling. Unlike traditional molds, micro molds often feature single- or few-cavity designs to ensure the utmost accuracy and precision.

2. Tolerances and Surface Finish

- Traditional Molds: The surface roughness for traditional molds typically falls within the Ra 0.2–0.8 μm range, which is suitable for most medical housings and connectors.

- Micro Molds: In micro molding, the surface finish is critical, with roughness as low as Ra 0.05 μm. This is essential for parts that require tight tolerances and smooth, biocompatible surfaces.

3. Thermal Management

- Traditional Molds: Thermal management is crucial in traditional molding, but it is less critical compared to micro molding due to larger shot sizes and slower cooling times.

- Micro Molds: In micro injection molding, temperature control is paramount. The small shot volumes and rapid heat transfer necessitate highly sophisticated thermal management systems, including conformal cooling and variothermal systems, to prevent premature solidification and ensure consistent part quality.

4. Machine and Process Considerations

- Traditional Molding Machines: Traditional injection molding machines generally have less resolution compared to micro machines. These machines can handle larger shot sizes and are well-suited for high-volume, low-precision applications.

- Micro Injection Machines: Micro injection molding requires specialized machines that can handle extremely small shot sizes with precision control. At LSRmold, we use state-of-the-art micro injection machines that feature precision screw or plunger systems for shot-to-shot control resolution below 0.1 mm³, ensuring the highest levels of accuracy and repeatability.

5. Materials Used

Both traditional and micro molding utilize medical-grade polymers, such as PEEK, LCP, PMMA, and PC. However, material selection in micro molding requires careful consideration of the flow characteristics at the micro-scale, including shear thinning and wall-slip phenomena.

6. Process Stability and Repeatability

- Traditional Molding: Traditional molding processes are more tolerant of variations in temperature, pressure, and material flow. While these processes are stable, they can accommodate a higher degree of fluctuation without negatively impacting the quality of the parts.

- Micro Molding: Micro injection molding demands precise control over all variables, including pressure, temperature, and material flow. Even minor fluctuations can lead to part rejection, which is why LSRmold uses real-time process monitoring and closed-loop control systems to ensure that each part meets the highest standards of quality.

7. Cost and Scalability

- Traditional Molds: Traditional molding tools are relatively less expensive to manufacture, and the cost per part decreases significantly with high production volumes. This makes traditional molding ideal for larger parts with simpler geometries.

- Micro Molding: Micro injection molding involves more expensive tooling and a longer setup time, which makes it less cost-effective for large production runs. However, the precision and miniaturization achieved with micro molding can provide significant cost savings in material usage and integration of features into a single part.

Application-Specific Considerations

| Application | Traditional Molding | Micro Molding |

|---|---|---|

| Syringe Barrels | ✓ | ✗ |

| Catheter Tips | ✓ | ✓ |

| Microneedle Arrays | ✗ | ✓ |

| Hearing Aid Components | ✓ | ✓ |

| Microfluidic Chips | ✗ | ✓ |

Both traditional and micro injection molding have their places in the medical device industry. Traditional molding remains a cost-effective option for larger components, while micro molding excels in producing ultra-small parts with extreme precision and high feature integration.

Why Choose LSRmold for Your Injection Molding Needs?

At LSRmold, we specialize in both micro and traditional injection molding for the medical device industry, offering high-precision manufacturing solutions that meet the rigorous standards set by regulatory bodies. Whether you’re developing a novel drug delivery system, diagnostic platform, or implantable device, our custom services ensure that your product is designed, manufactured, and delivered to the highest quality standards.

Our one-stop service includes in-house design, prototyping, tooling, and full-scale production capabilities, ensuring your products meet all ISO 13485 and FDA requirements. Our expertise in both micro and traditional injection molding allows us to choose the best approach for your specific application, providing the highest quality parts with the precision and durability your medical devices demand.

Contact us today to learn how LSRmold can support your medical device manufacturing needs. From concept to production, we are your trusted partner in delivering high-quality, high-precision medical components.