Overview:

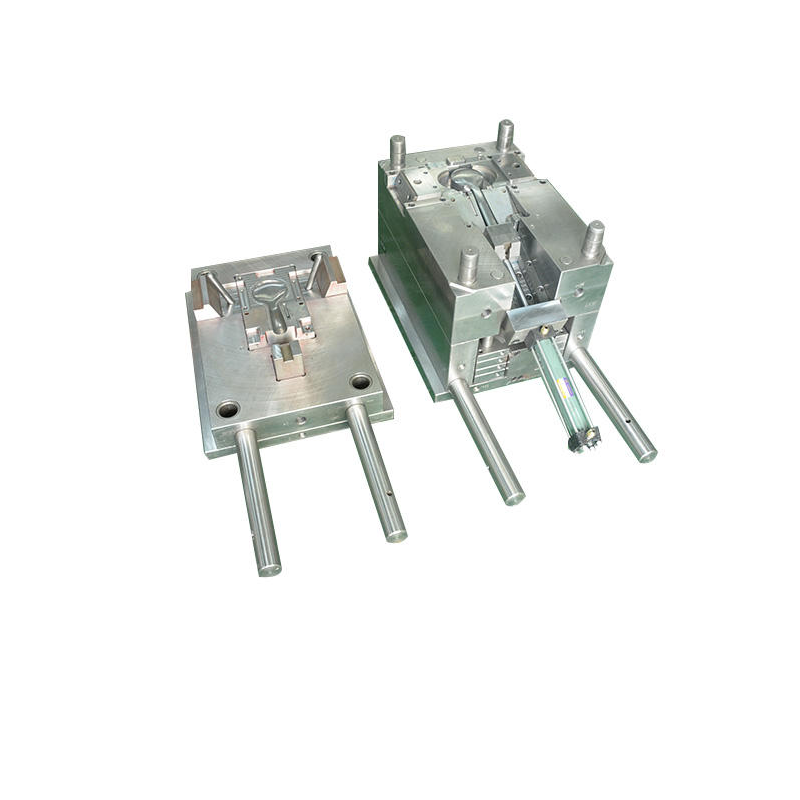

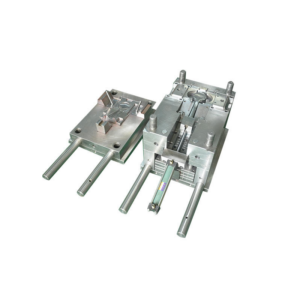

Our OEM Plastic Injection Molding Tooling Mould for Bathroom Shower Head Accessories is engineered for precision and durability, specifically designed to produce high-quality shower head components. Constructed from premium materials such as steel or aluminum, these molds utilize cutting-edge CNC machining and Wire EDM (Electrical Discharge Machining) to ensure high precision and efficiency in every phase of production. Whether it’s for mass production or custom tooling, our advanced manufacturing processes deliver consistent, reliable, and cost-effective results, adhering to rigorous industry standards, including ISO 9001 and IATF 16949 certifications. These molds are designed to meet the specific needs of the bathroom accessories industry, ensuring superior performance and long-lasting durability for shower head components and accessories.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Steel, Aluminum |

| Runner System | Hot/Cold Runner |

| Mould Design Software | UG, PROE, SOLIDWORKS, CAD, etc. |

| Sample | Available |

| Certification | ISO9001, IATF16949 |

| Packaging | Custom |

| MOQ | According to your requirements |

| Lead Time | 25-30 days |

Surface Treatment Options:

- Nickel Plating: Provides exceptional corrosion resistance, improving the longevity of the mold and ensuring it can withstand harsh bathroom environments with frequent exposure to water and chemicals.

- Hard Anodizing: Increases the surface hardness and wear resistance of the mold, ensuring durability even with high-frequency use in production cycles.

- Chromium Plating: Delivers superior protection against wear, corrosion, and environmental factors, extending the life of the mold.

- Polishing: Refines the surface finish, reducing friction and improving the quality of molded shower head components by minimizing defects during production.

Quality Assurance:

Our quality assurance process for the OEM Plastic Injection Molding Tooling Mould for Bathroom Shower Head Accessories ensures that each mold meets the highest industry standards for quality, precision, and durability. Adhering to ISO 9001 and IATF 16949 certifications, we follow rigorous testing protocols at each stage of production. The key components of our QA process include:

- First-article evaluations to ensure the design and functionality meet specifications before full production.

- In-process audits throughout the molding process to detect any potential defects early and minimize waste.

- Final product assessments to verify dimensional accuracy and quality before delivery.

We employ a range of advanced testing equipment to ensure each mold meets the required standards:

- Coordinate Measuring Machines (CMM): For verifying precise dimensions of the mold and components.

- Hardness Testers: To ensure the material hardness of the mold meets the specified standards.

- Surface Roughness Analyzers: To measure the finish quality and ensure optimal mold surface texture.

- Automated Vision Systems: For visual inspection of mold quality and surface defects, ensuring consistency and reliability across production batches.

These processes ensure that each mold is of the highest quality, providing the durability and precision needed for the production of shower head accessories.

Why Choose Us?

- Precision Engineering: Our use of Wire EDM and CNC machining ensures superior mold accuracy and efficiency, leading to high-quality components with precise dimensions and a smooth surface finish.

- Custom Solutions: We specialize in providing tailored mold designs to meet your specific requirements, whether it’s for custom shapes, sizes, or unique features for shower head accessories.

- Advanced Technology: Our facility is equipped with cutting-edge technologies such as CNC machining centers, Mirror EDM, and high-precision wire cutting systems to achieve the highest mold quality.

- Rigorous Quality Control: Every mold undergoes extensive quality testing using state-of-the-art equipment to guarantee performance, durability, and dimensional accuracy.

- Efficient Production: With our automation systems—such as AutoDryers, high-speed doming machines, and precision die-cutting technology—we can ensure rapid and consistent production while maintaining the highest quality.

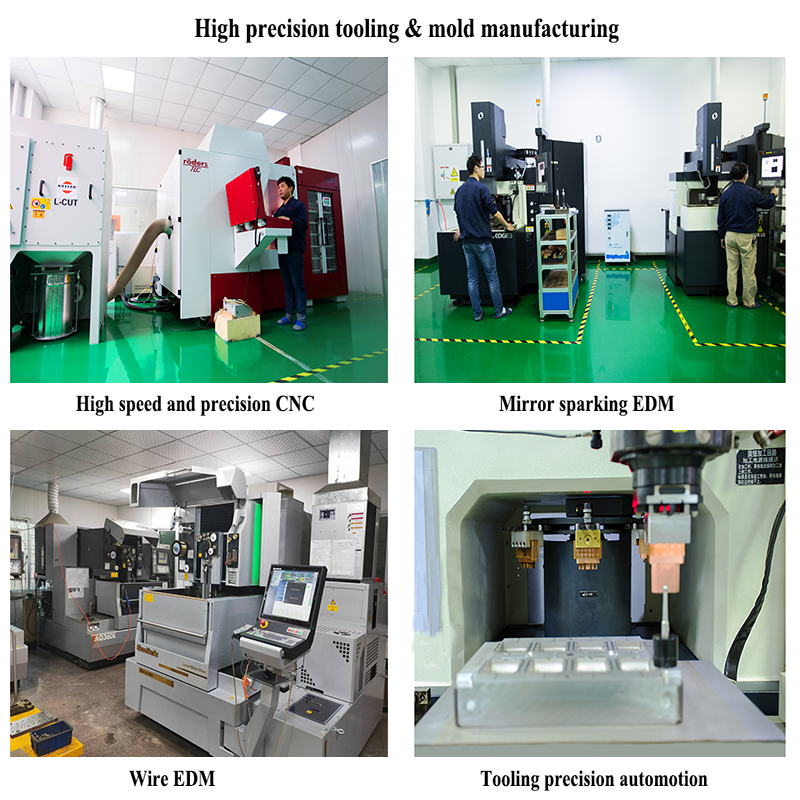

Factory Show:

Our advanced manufacturing facility is equipped with CNC machining centers, Mirror EDM, conventional EDM, and slow-speed wire-cutting systems, enabling us to achieve high-precision mold fabrication. We operate 15 rubber compression presses and 2 LSR injection molding machines, allowing us to handle both high-volume production and custom tooling projects.

In our quality control department, we utilize tools such as 3D optical projectors, sealing testers, durometers, and elasticity gauges to ensure the highest level of accuracy and consistency. These are overseen by our certified QA specialists who follow stringent inspection protocols to guarantee reliable, high-performance manufacturing.

We are ISO 9001 and IATF 16949 certified, ensuring that all processes adhere to global quality standards. With automation systems in place, we are able to streamline production, enhance precision, and increase operational efficiency, ensuring that each mold is of the highest quality and meets your exact specifications for bathroom shower head accessories.

Partner with us for your OEM Plastic Injection Molding Tooling Mould for Bathroom Shower Head Accessories and ensure that your production process runs smoothly, efficiently, and with top-notch quality.