In the world of electronics manufacturing, protecting delicate components such as printed circuit boards (PCBs), connectors, and sensors from external environmental factors like moisture, dust, and physical damage is critical. Traditional methods like potting, conformal coatings, and hermetic sealing, although widely used, have long been recognized for their limitations. These methods often struggle to achieve consistent encapsulation and have a higher risk of damage to sensitive parts due to the high temperatures and harsh chemicals involved.

Enter Low Pressure Injection Molding (LPIM), a cutting-edge solution that has transformed the way electronics are encapsulated and protected. By applying thermoplastic materials under low pressure (typically between 20 and 580 psi) and moderate temperature (356°F to 428°F), LPIM provides a more controlled, cost-effective, and efficient way to protect sensitive electronics. With LPIM, manufacturers can achieve higher-quality encapsulation without the risk of damaging delicate components. In this blog, we’ll explore how low-pressure injection molding has revolutionized the electronics industry and why it’s a game-changer for manufacturers.

What is Low Pressure Injection Molding (LPIM)?

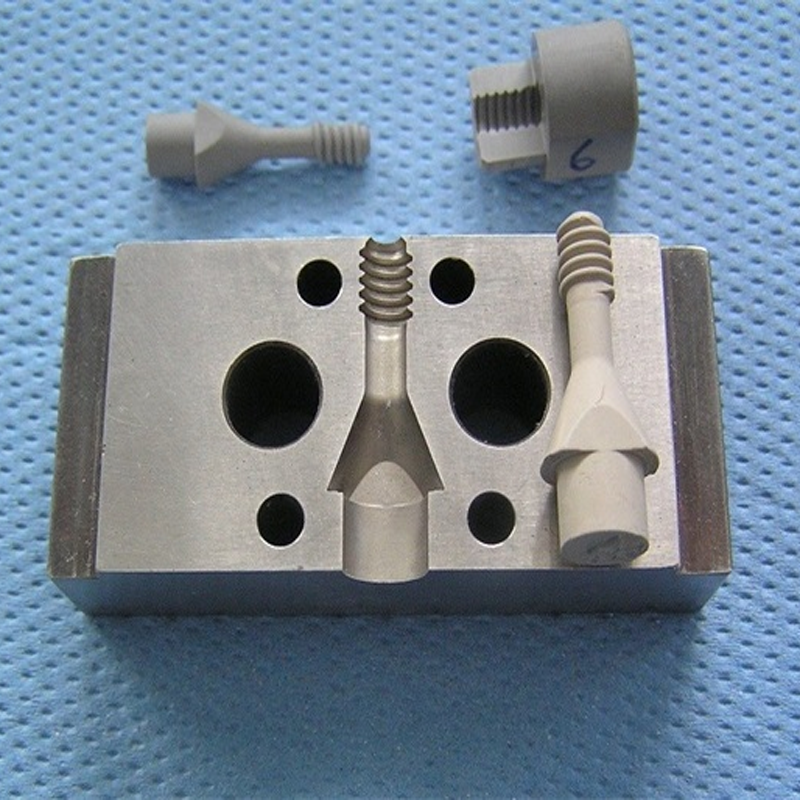

Low Pressure Injection Molding is a method of encapsulating electronic components using thermoplastic materials like polyamides (nylon), polycarbonates, and silicones. These materials are injected into molds at lower pressures and temperatures compared to traditional injection molding processes. The primary advantage of LPIM is that it allows for the encapsulation of delicate components such as PCBs and connectors without subjecting them to damaging high temperatures or excessive pressure, which could otherwise cause harm.

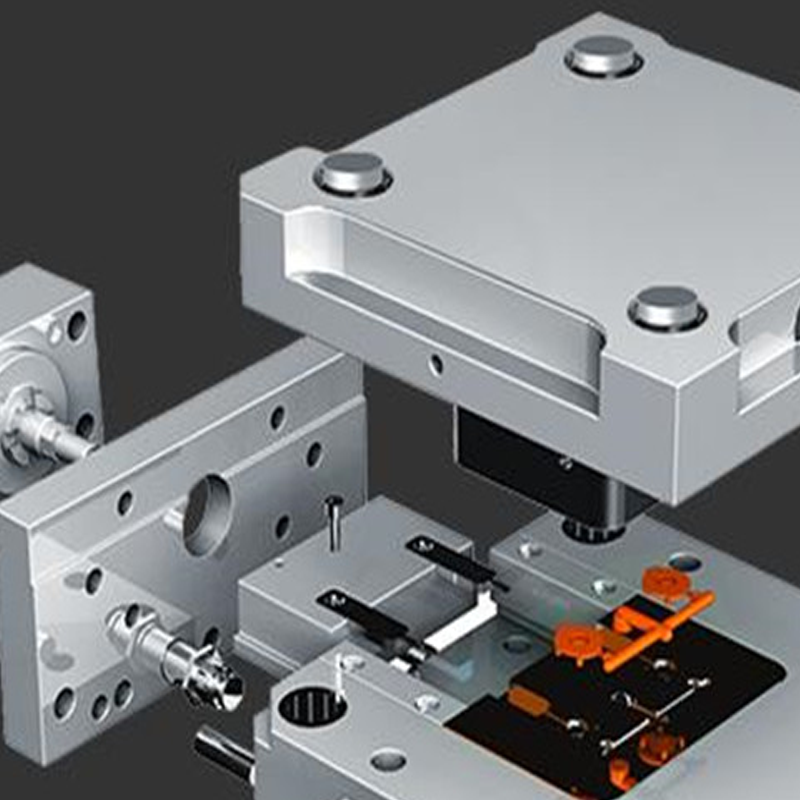

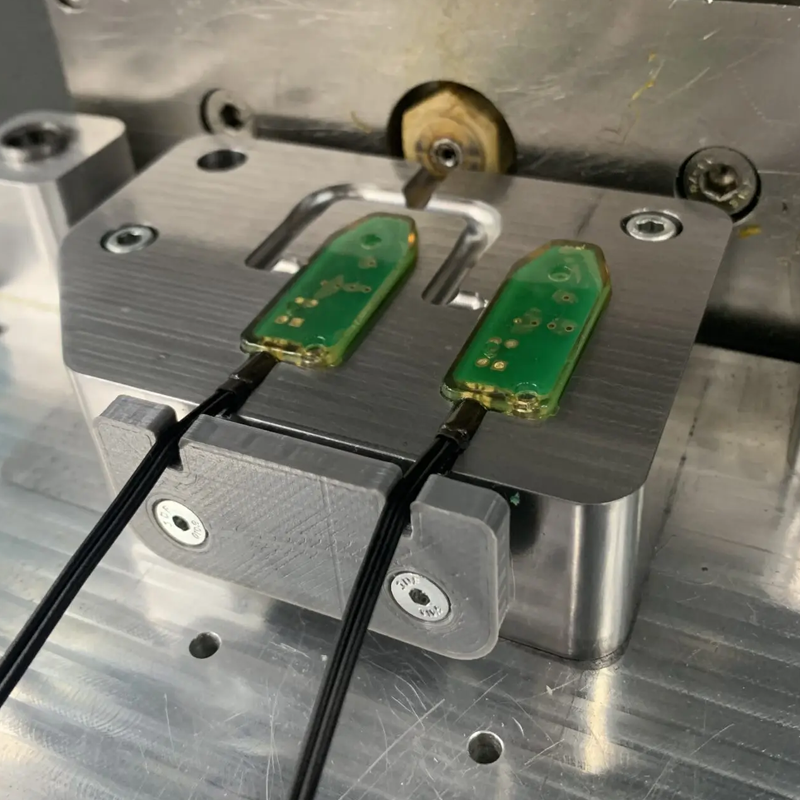

This process involves melting the selected thermoplastic material, injecting it into a mold cavity containing the electronic component, and then allowing it to cool and solidify. The result is a highly durable, moisture-resistant, and protective coating around the electronic part, ensuring its functionality and longevity in challenging environments.

Key Materials Used in Low Pressure Injection Molding

Choosing the right material is crucial for ensuring the success of low-pressure injection molding. The material selected will influence the final product’s mechanical properties, chemical resistance, and environmental adaptability. Some of the most common materials used in LPIM include:

- Polyamides (Nylon): Known for excellent mechanical strength and durability, nylon is ideal for general-purpose applications. It is also abrasion-resistant and offers good processability.

- Polycarbonates (PC): Offering exceptional clarity, strength, and impact resistance, polycarbonate is often chosen for its optical properties and overall strength.

- Polyurethanes (PU): Known for its flexibility and resistance to impact, polyurethane is often used in applications that require a soft touch or increased elasticity.

- Polyolefins (PO): This material is affordable and easy to process, making it a popular choice for applications where cost is a primary consideration.

- Silicones: Particularly useful for temperature-sensitive applications, silicone offers superior resistance to both heat and chemicals, making it ideal for medical devices and high-temperature environments.

- Epoxy Resins: Known for their excellent electrical insulation properties, epoxy resins are commonly used for applications that require high chemical resistance and electrical insulation.

Steps Involved in Low Pressure Injection Molding

The LPIM process is relatively simple compared to traditional encapsulation methods, which involve multiple steps and the use of chemicals. LPIM can be broken down into four essential steps:

- Heating the Molding Material: The selected thermoplastic material is heated to a liquid state at a temperature suited to the material’s specifications.

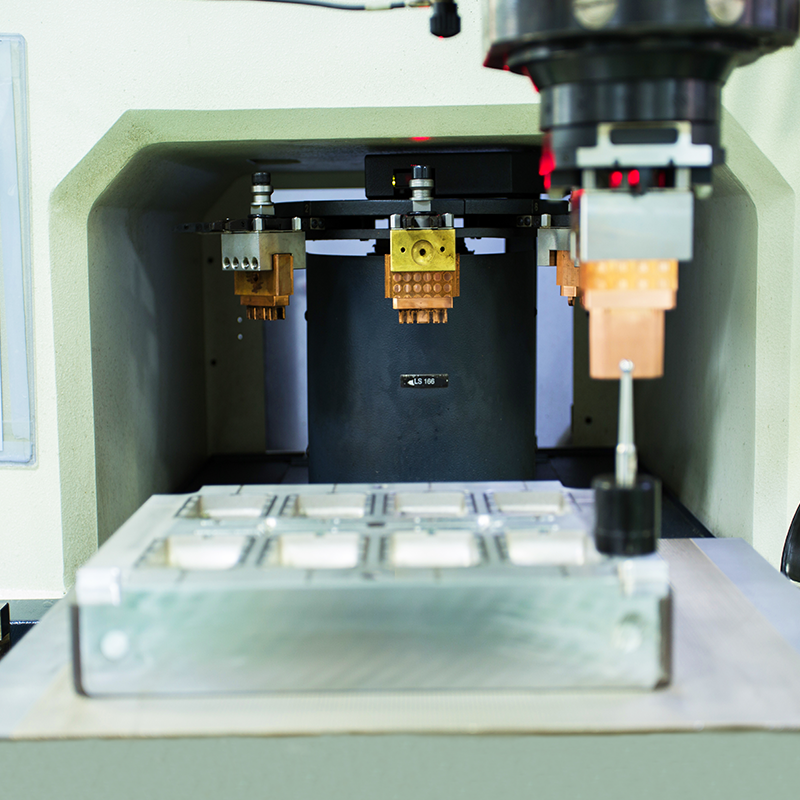

- Placing the Component: The electronic component to be encapsulated is positioned in one half of the mold cavity. The mold is then closed.

- Injection of Molding Material: The molten thermoplastic material is injected into the mold cavity at low pressure, ensuring the encapsulation of the component without damaging it.

- Cooling: After the material is injected, it is allowed to cool and solidify, forming a durable protective layer around the component.

LPIM vs. Traditional Processes: A Technical Comparison

LPIM offers several key advantages over traditional encapsulation techniques, such as potting and conformal coatings. Let’s take a look at how LPIM stacks up in comparison:

| Property | Low Pressure Injection Molding | Potting |

|---|---|---|

| Steps | Fewer steps, simpler process | More steps, labor-intensive |

| Curing Time | Seconds (5 to 50 seconds) | Hours or days |

| Material Use | More efficient, less material waste | High material waste |

| Recycling | Thermoplastics can be recycled | Excess material not recyclable |

| Environmental Impact | Lower environmental impact with recyclable materials | Potential for toxic fumes and waste |

| Cost | More cost-effective over time | Higher costs due to labor and material waste |

| Human Intervention | Can be automated, reducing errors | Requires more manual labor |

| Weight of Part | Lightweight due to thin coating | Heavier due to thick coating |

As you can see, LPIM offers significant advantages in terms of speed, efficiency, material savings, and environmental impact when compared to traditional potting processes.

Addressing Major Pain Points in Electronics Manufacturing with LPIM

Traditional encapsulation methods have long faced three major pain points in electronics manufacturing:

- Packaging Efficiency for Precision Components: Traditional methods like conformal coating and potting struggle to achieve consistent sealing across components with complex geometries, such as circuit boards with varying component sizes and orientations. LPIM, on the other hand, provides uniform encapsulation, ensuring complete protection for every component.

- High Damage Rates of Thin-Walled Parts: The labor-intensive nature of traditional methods increases the risk of damaging thin-walled parts, especially when curing compounds generate excessive heat. LPIM eliminates this risk by applying lower pressure and temperature, protecting delicate components during the molding process.

- High Costs and Environmental Concerns: Traditional potting techniques involve high material consumption and significant labor costs. In contrast, LPIM reduces material waste, operates faster, and can be automated, leading to lower overall costs and less environmental impact.

Low Pressure Injection Molding Technical Implementation Guidelines

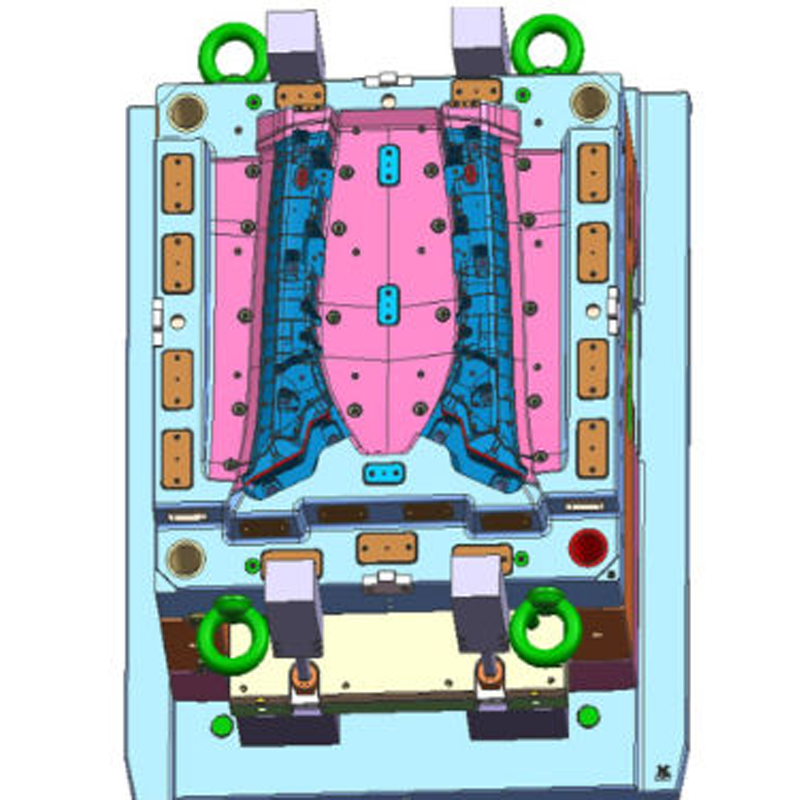

For successful LPIM implementation, manufacturers must carefully consider factors such as material selection, mold design, and machine setup. These elements play a critical role in achieving consistent, high-quality results:

- Material Selection: Choose materials with the appropriate properties for the intended application, such as resistance to heat, moisture, and chemicals.

- Mold Design: Ensure uniform wall thickness and proper gate design to prevent weld lines. Avoid sharp corners that can lead to stress concentration and cracks.

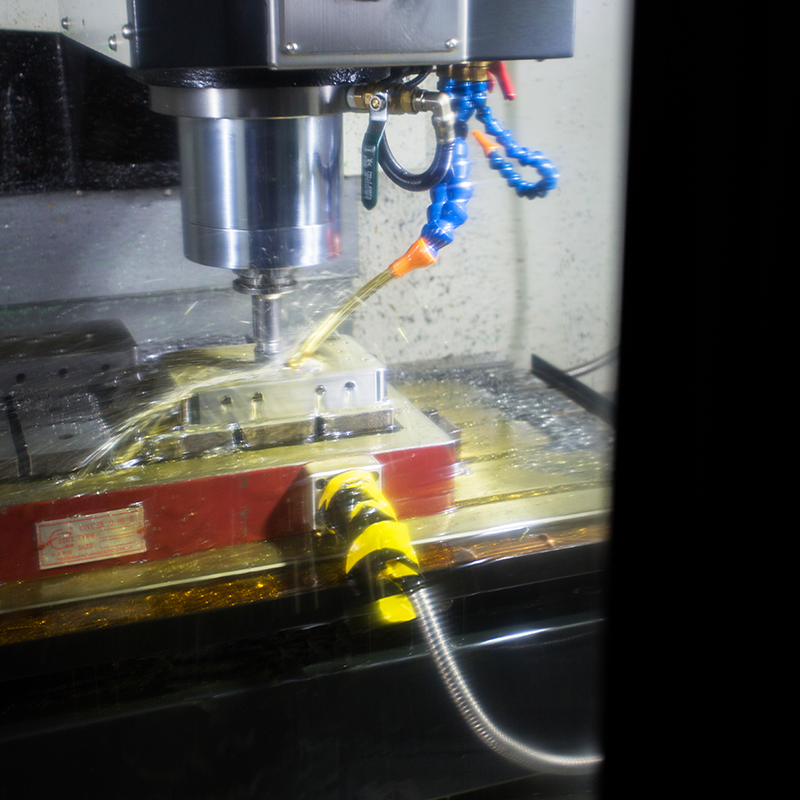

- Molding Machine Setup: Optimize temperature, pressure, and injection speed to suit the material and component requirements.

- Process Control: Continuously monitor and document molding parameters to ensure consistent part quality.

Applications of Low Pressure Injection Molding

LPIM has a wide range of applications across various industries. Some key sectors include:

- Electronics Industry: Used for encapsulating PCBs, connectors, and other sensitive components, providing protection from moisture, dust, and physical damage.

- Automotive Industry: Used for overmolding materials to substrates, especially for components like door guards and parcel shelf guards.

- Medical Devices: Ensures the safe encapsulation of sensitive medical components, offering protection against sterilization processes and external damage.

- Aerospace Industry: Used to seal cable connections and other critical components, providing long-lasting protection in harsh environments.

Conclusion: Embracing the Future of Electronics Encapsulation with LPIM

Low Pressure Injection Molding is a revolutionary technology that offers substantial benefits over traditional encapsulation methods. With its ability to protect delicate electronic components while improving efficiency, cost-effectiveness, and environmental sustainability, LPIM is the preferred choice for many manufacturers today. At LSRmold, we specialize in providing high-quality LPIM solutions that meet the unique needs of our clients, offering a comprehensive range of services from design to manufacturing.

Are you looking to explore low-pressure injection molding for your next electronics project? Contact us at LSRmold, where we offer custom solutions tailored to your specific needs, ensuring your products meet the highest standards of quality, performance, and environmental responsibility. Our OEM services and one-stop manufacturing capabilities make us the ideal partner for your next project.