Overview:

Our high-precision OEM Hot Runner Silicone Ketchup Salad Bottle Cap Lids Mold Tooling is meticulously designed for the production of durable, leak-proof silicone caps for condiment and food packaging applications. Engineered with advanced technology, these molds are capable of producing high-quality silicone components with seamless functionality. Constructed from premium tool steels such as P20, H13, or high-quality aluminum alloys, these molds utilize cutting-edge hot runner systems to ensure uniformity and consistency in molding. We specialize in complex geometries, catering to specific material requirements for high-performance thermoplastic elastomers (TPE) and silicone materials. With an ISO 9001:2015 certification and full compliance with food-grade manufacturing standards, our molds guarantee superior product quality for OEMs in the food packaging industry. Our comprehensive service includes prototyping, mass production, and post-production inspections to ensure the final product meets the highest standards of durability, flexibility, and performance.

![]()

![]()

Basic Information:

| Basic Information | Details |

|---|---|

| Mold Type | Hot Runner Silicone Injection Mold |

| Mold Material Options | P20, 718, 738, NAK80, S136 |

| Mold Base Standards | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mold Runner System | Hot Runner |

| Mold Gate Options | Pin-point Gate, Sub Gate |

| Cavity | Multi-Cavity |

| Design Software Supported | UG, PROE, CAD, SOLIDWORKS |

| Molding Equipment Used | CNC, Wire Cutting, Milling Machine, EDM, Hot Runner |

| Compatible Raw Materials | Liquid Silicone Rubber (LSR), Thermoplastic Elastomers (TPE) |

| Packaging Method | Wooden Pallet or Carton |

| OEM Services | Available — Please provide 2D/3D files or samples |

| Lead Time | Approximately 30 days |

Advantages of Our Molds:

- Precision Engineering for High-Performance Caps: Achieves flawless molding for tight tolerances, essential for ensuring leak-proof performance in food packaging.

- Durability for Extended Mold Life: Manufactured using premium steel materials, resulting in a robust mold structure capable of withstanding extended production runs.

- Rapid Production Cycle: Hot runner technology allows for consistent, high-speed molding, reducing cycle times and improving productivity.

- Food-Safe Materials and Processes: Our molds are produced in full compliance with food-grade safety standards, ensuring safe, reliable products for use in the food industry.

- Superior Surface Finish: Achieved through advanced EDM texturing and polishing, ensuring smooth, aesthetically pleasing surfaces on the caps and lids.

Surface Coating Options:

- Titanium Nitride (TiN) Coating: Offers enhanced wear resistance and minimizes friction in high-temperature environments, making it ideal for continuous silicone molding operations.

- Diamond-Like Carbon (DLC) Coating: Ultra-low friction and exceptional corrosion resistance make DLC an excellent choice for molds exposed to food-grade silicones and other demanding materials.

- Hard Chrome Plating: Provides excellent corrosion resistance and surface hardness (up to 70 HRC), ensuring the mold’s durability and extended lifespan.

- PVD Multilayer Coatings (e.g., CrN or AlCrN): Achieves a perfect balance of hardness, thermal stability, and excellent release properties, especially beneficial for multi-cavity molds handling complex geometries.

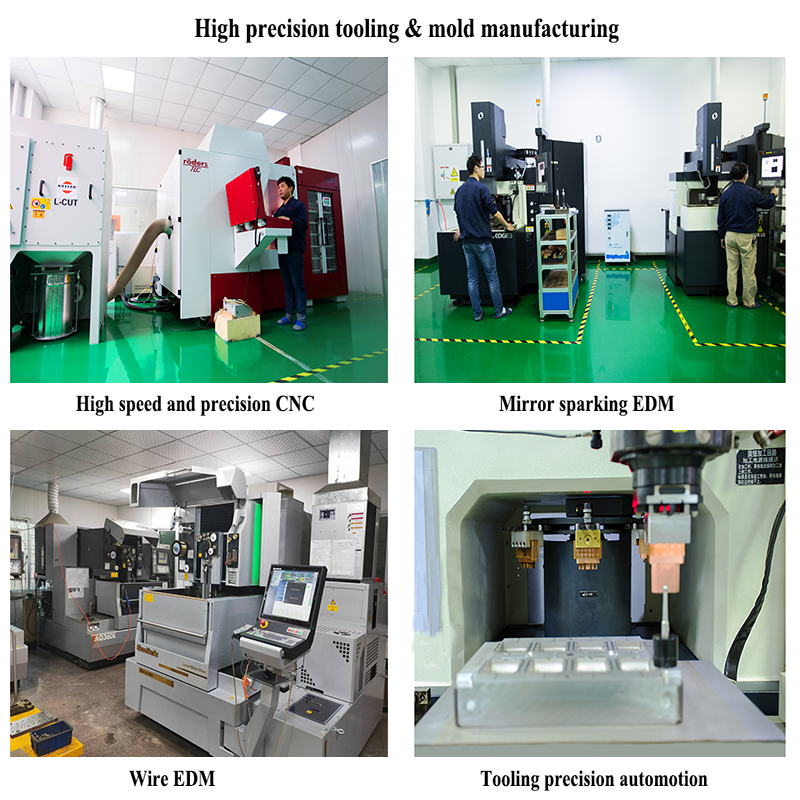

Factory Show:

Our state-of-the-art manufacturing facility is equipped with the latest technologies for producing precision silicone molding tools. Key equipment includes CNC machining centers, Mirror EDM, Slow-Speed Wire Cut (WC), and Hot Runner systems, allowing us to deliver high-quality results with superior accuracy. We also maintain a fleet of rubber compression molding machines and LSR injection molding machines to ensure flexibility in production and fast turnaround times.

Our certified quality control team uses advanced testing equipment such as 3D projectors, sealing testers, durometers, and elasticity measurement devices to ensure the highest standards of quality are met. Adhering to ISO 9001:2015 and IATF 16949 certifications, we guarantee consistent and reliable performance.

Production and Post-Production Services:

- Prototyping: We offer a fast-track prototyping service to validate the design and material specifications of the silicone bottle cap molds.

- Mold Flow Analysis: Prior to production, we use mold-flow analysis tools to optimize mold designs, ensuring the best possible material flow and minimizing defects.

- Post-Production Inspections: Every mold is subjected to comprehensive inspections for dimensional accuracy, surface finish quality, and material properties before delivery.

Our commitment to quality and customer satisfaction ensures that you receive the highest-quality molds, optimized for precision, performance, and durability in silicone ketchup and salad bottle cap lid manufacturing.