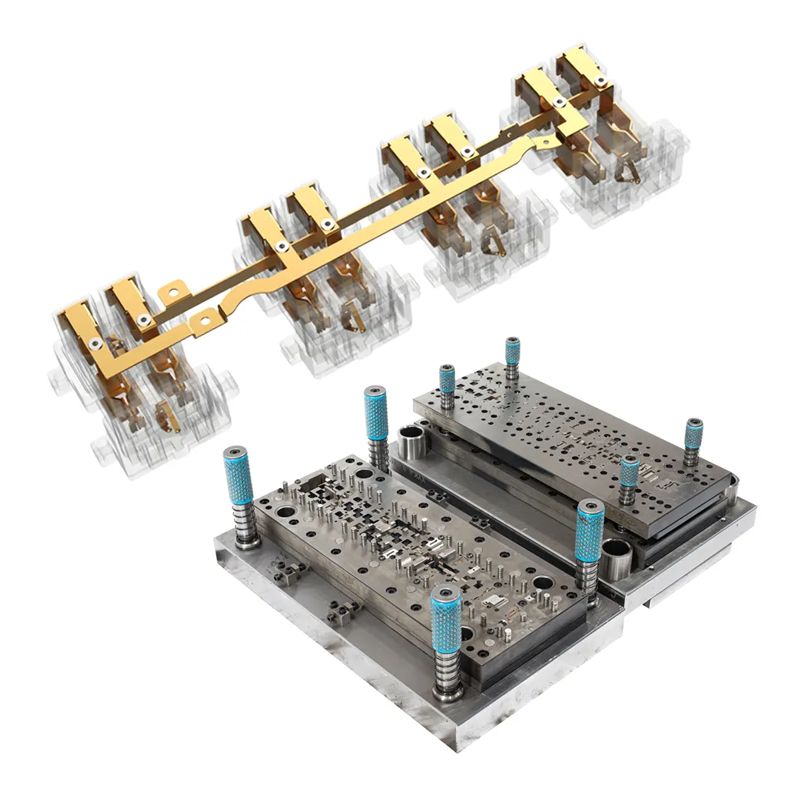

Overview:

Our personalized precision metal stamping punching die molds are engineered for the high-volume production of miniature circuit breaker (MCB) components and wall switch socket parts. Crafted from premium die steels such as D2, A2, or S7, these molds deliver exceptional dimensional accuracy and repeatability down to the micron level. We leverage advanced CNC machining, high-precision wire EDM, and automated turret presses to realize complex features—slots, embossments, and lanced tabs—while maintaining tight tolerances. Designed for both single-station and progressive die applications, our tooling accommodates materials ranging from cold-rolled stainless steel to high-strength copper alloys. Fully customizable to your electrical housing geometries and assembly requirements, these dies ensure leak-proof fit, electrical insulation clearances, and smooth actuation. From initial prototyping to full production runs, we offer one-stop service—tool design validation, pilot runs, and in-die sensing integration—so OEMs and switchgear suppliers can achieve rapid time-to-market and consistent quality.

Basic Specifications:

| Specification | Details |

|---|---|

| Mold Type | Metal Stamping Punching Die Mold |

| Die Steel Options | D2, A2, S7, H13 |

| Die Base Standards | PUNCH, PROGRESSIVE, TRANSFER |

| Cavity Configuration | Single-Station & Progressive Multi-Stage |

| Press Compatibility | Mechanical Presses (30–400 ton), Servo-Drive Presses |

| Steel Thickness Range | 0.2 mm – 3.0 mm |

| Tolerance Capability | ±0.02 mm |

| Material Compatibility | Cold-Rolled Steel, Stainless Steel (301, 304), Copper Alloys |

| Tooling Software | UG NX, SOLIDWORKS, AutoForm |

| Production Machinery | CNC Milling, Wire EDM, Surface Grinding, Automated Press Lines |

| Prototype Lead Time | 2–3 weeks |

| Production Lead Time | 4–6 weeks (dependent on complexity and cavity count) |

| OEM & Custom Services | Available – Provide 2D/3D CAD files or physical samples |

Key Advantages of Our Dies:

- Unmatched Durability: Die steels heat-treated to 60–62 HRC for long tool life under high-cycle stamping.

- Micro-Precision: Machining and EDM processes ensure edge radii as small as 0.1 mm for crisp, electrified contact surfaces.

- Versatile Die Configurations: From simple piercing and blanking to progressive dies with multi-operation stations—draw, form, pierce, and trim—in a single tool.

- Integrated In-Die Sensors: Optional load and position sensors enable real-time process monitoring and feedback for zero-defect production.

- Rapid Changeover: Modular die inserts and quick-release guide bushings minimize downtime during material grade or part design updates.

Surface Treatment & Coating Options:

- Nitride Coating (TiN): Increases surface hardness (to 2,400 HV) and reduces friction for smoother strip feed and longer die life.

- Diamond-Like Carbon (DLC): Provides ultra-low friction and superior corrosion resistance, ideal for high-humidity or chloride-rich environments often found inside switchgear.

- Hard Chrome Plating: Ensures uniform hardness and excellent wear resistance while maintaining electrical insulation gaps.

- PVD Multi-Layer Coatings (CrN/AlCrN): Delivers outstanding thermal stability and anti-adhesion properties, critical for rapid stamping cycles.

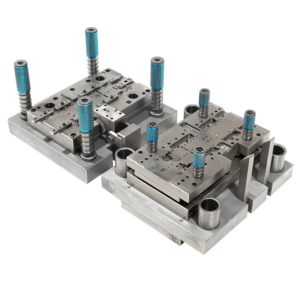

Factory Capabilities:

Our ISO 9001:2015 and IATF 16949 certified facility houses:

- CNC Machining Centers & Wire EDM Machines: For precise die cavity and punch fabrication.

- Surface Grinding & Lapping: To achieve mirror-finish die surfaces and ensure uniform metal flow.

- Automated Press Lines: Servo-driven stamping presses (50–300 ton)—capable of high-speed, high-accuracy production.

- In-House Toolroom: Dedicated toolmakers for die assembly, trial runs, and quick modifications.

- Quality Inspection: 3D CMM inspections, optical comparators, and hardness testing to verify all die features meet specification before delivery.

With a comprehensive one-stop service model—from conceptual DFM reviews to volume production support—we partner with electrical component manufacturers and switchgear suppliers to deliver precision stamping tools that power your products’ reliability and performance.