Overview:

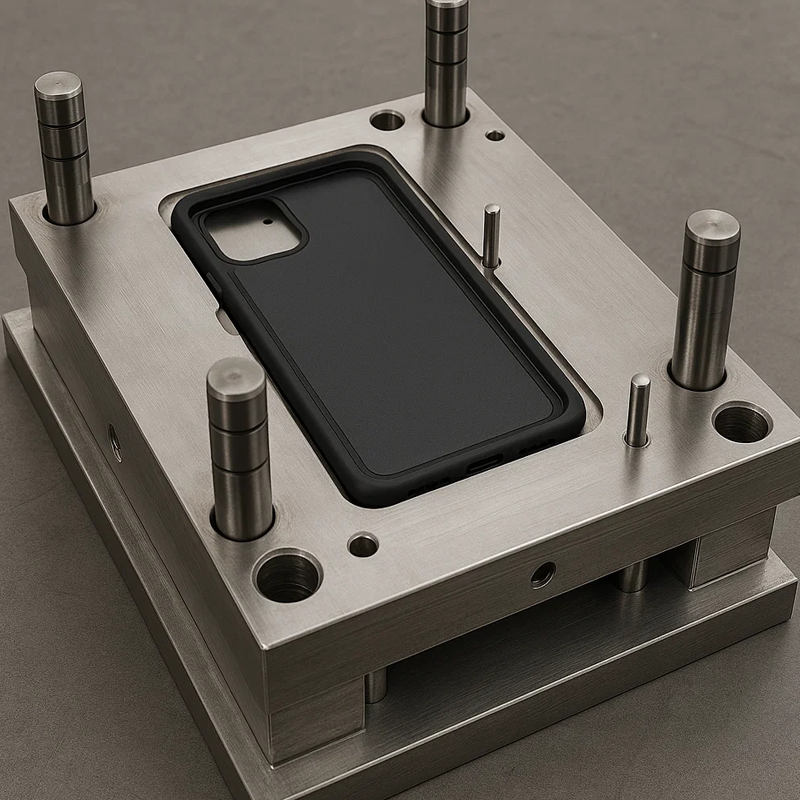

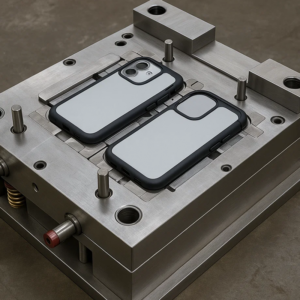

The Customized P20 Steel, S136 Steel Phone Case Overmolding Mould Tooling is a highly advanced solution designed to manufacture durable, high-quality phone case components. Crafted from premium P20 and S136 steel, known for their exceptional strength, wear resistance, and corrosion resistance, these molds utilize advanced EDM techniques to achieve precise, consistent results for phone case overmolding. Our experienced team provides comprehensive one-stop services, offering fully customizable solutions to meet your unique specifications, ensuring both cost-effectiveness and superior product performance. These molds are built to adhere to the highest quality standards, including IATF 16949, guaranteeing long-lasting durability in demanding mobile accessory applications.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | P20 Steel, S136 Steel |

| Runner System | Hot Runner, Cold Runner |

| Mould Design Software | UG, PROE, SOLIDWORKS, CAD, etc. |

| Sample | Available |

| Certification | ISO 9001, IATF 16949 |

| Packaging | Custom |

| MOQ | According to your requirement |

| Lead Time | 25–30 days |

Surface Treatment Options:

- Nickel Plating: Offers superior corrosion resistance and durability, extending the mold’s lifespan in rigorous mobile accessory production environments.

- Hard Anodizing: Enhances surface hardness and wear resistance, ideal for high-precision overmolding applications.

- Chromium Plating: Provides exceptional protection against wear and corrosion, ensuring long-term mold performance.

- Polishing: Refines the surface finish, reducing friction during the molding process and improving the quality of overmolded components.

Quality Assurance:

Our quality assurance process for Customized P20 Steel, S136 Steel Phone Case Overmolding Mould Tooling ensures precise manufacturing standards and compliance with ISO 9001 and IATF 16949 certifications. We implement robust inspection procedures including first-article evaluations, in-process audits, and final product assessments. Advanced tools such as coordinate measuring machines (CMM), hardness testers, and surface roughness analyzers are used to guarantee dimensional accuracy and material integrity. Our automated vision systems and comprehensive material testing ensure the consistency, reliability, and durability of each mold, meeting the highest industry standards.

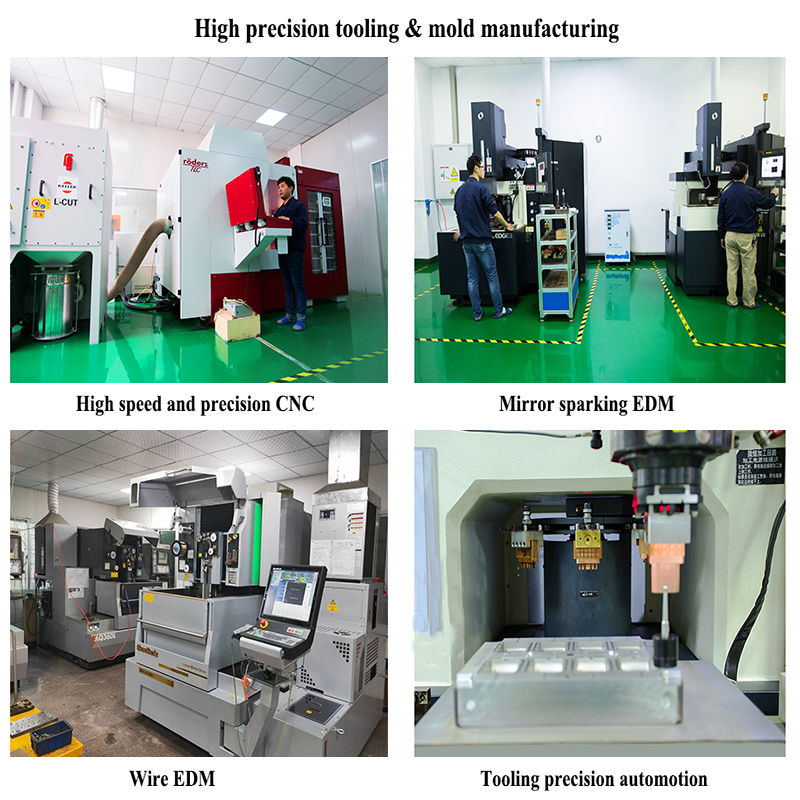

Factory Show:

Our advanced manufacturing facility is equipped with cutting-edge technologies, including CNC machining, Mirror EDM, conventional EDM, and slow-speed wire cutting (WC) to ensure the highest precision in mold fabrication. With a fleet of rubber compression molding presses and LSR injection molding machines, we are able to scale production efficiently while ensuring consistent performance. We maintain top-tier standards using inspection tools such as 3D projectors, sealing testers, durometers, and elasticity gauges, all overseen by our certified quality control team. Fully compliant with ISO 9001 and IATF 16949, we ensure dependable, high-performance manufacturing. Our automated systems, such as AutoDryers, high-speed doming machines, and precision die-cutting technology, enhance productivity, precision, and product quality, maintaining consistency throughout every stage of production.